Wide preparation window and preparation method of spontaneous textured perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems that the surface of perovskite cannot be textured and has no reliable method, so as to achieve the effect of improving fault tolerance and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

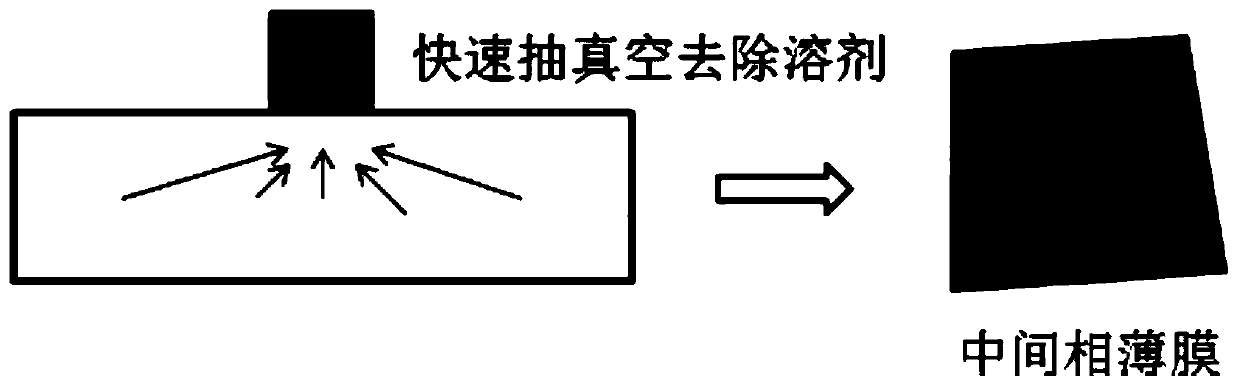

Method used

Image

Examples

Embodiment 1

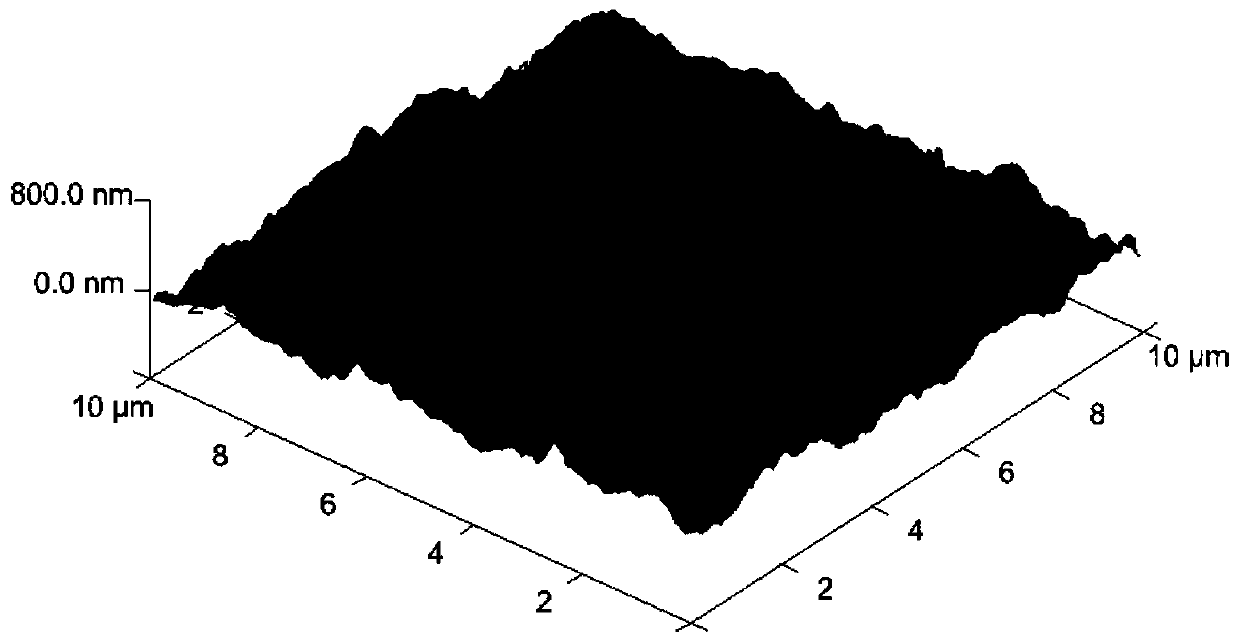

[0021] 1. The suede FTO glass is ultrasonically passed through acetone, alcohol, and isopropanol for 15 minutes respectively, and then blown dry with nitrogen. Among them, the haze of FTO glass is not less than 17%, and the sheet resistance is not higher than 7omh / sq. Before use , by UV-ozone treatment for 15 min.

[0022] 2. Prepare the electron transport layer. The material of the electron transport layer is titanium oxide with a thickness of 30nm. The specific steps are to immerse the cleaned FTO glass into a 0.2M titanium tetrachloride aqueous solution, and the aqueous solution is heated from room temperature to 70°C , lasted for 75 minutes, after that, rinsed with deionized water, and then dried with nitrogen gas for later use.

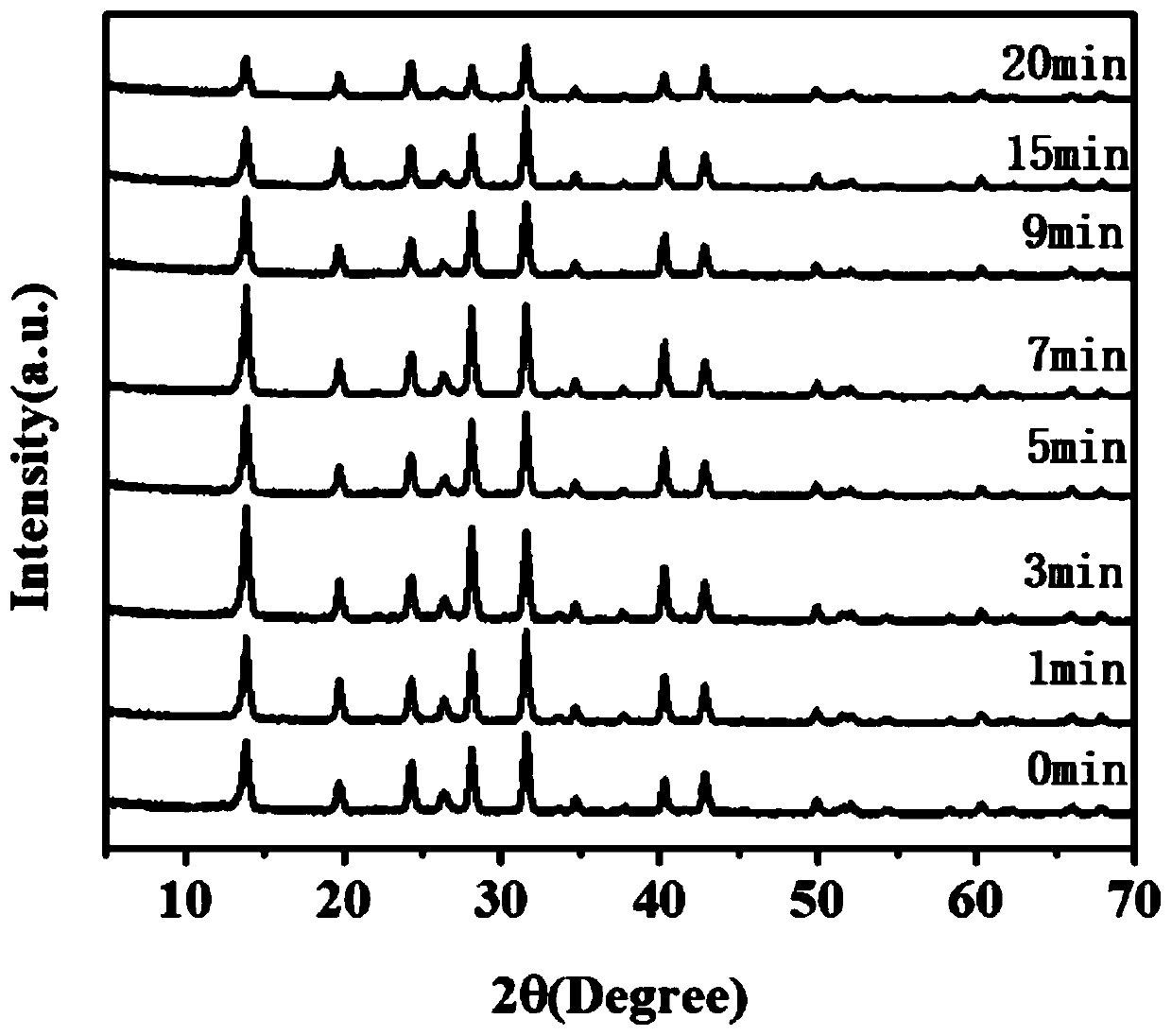

[0023] 3. Dissolve 3.507g of cesium iodide, 0.76g of methylamine bromide, 2.48g of lead bromide, 59.12g of lead iodide, and 19.74g of formamidine iodide into 100mL of a mixed solvent to obtain a perovskite precursor solution, Among them, the mix...

Embodiment 2

[0030] 1. The suede FTO glass is ultrasonically passed through acetone, alcohol, and isopropanol for 15 minutes respectively, and then blown dry with nitrogen. Among them, the haze of FTO glass is not less than 17%, and the sheet resistance is not higher than 7omh / sq. Before use , by UV-ozone treatment for 15 min.

[0031] 2. Prepare the electron transport layer. The material of the electron transport layer is titanium oxide with a thickness of 30nm. The specific steps are to immerse the cleaned FTO glass into a 0.2M titanium tetrachloride aqueous solution, and the aqueous solution is heated from room temperature to 70°C , lasted for 75 minutes, after that, rinsed with deionized water, and then dried with nitrogen gas for later use.

[0032] 3. Dissolve 3.507g of cesium iodide, 0.76g of methylamine bromide, 2.48g of lead bromide, 59.12g of lead iodide, and 19.74g of formamidine iodide into 100mL mixed solvent to obtain a perovskite precursor solution, wherein , the mixed solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com