Centrifugal pump impeller sealing structure

A centrifugal pump impeller, centrifugal wheel technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of improving pump efficiency, poor sealing effect, friction power consumption of front and rear bosses, etc., to achieve stability and structure. High reliability, stable leakage cooling flow, and the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

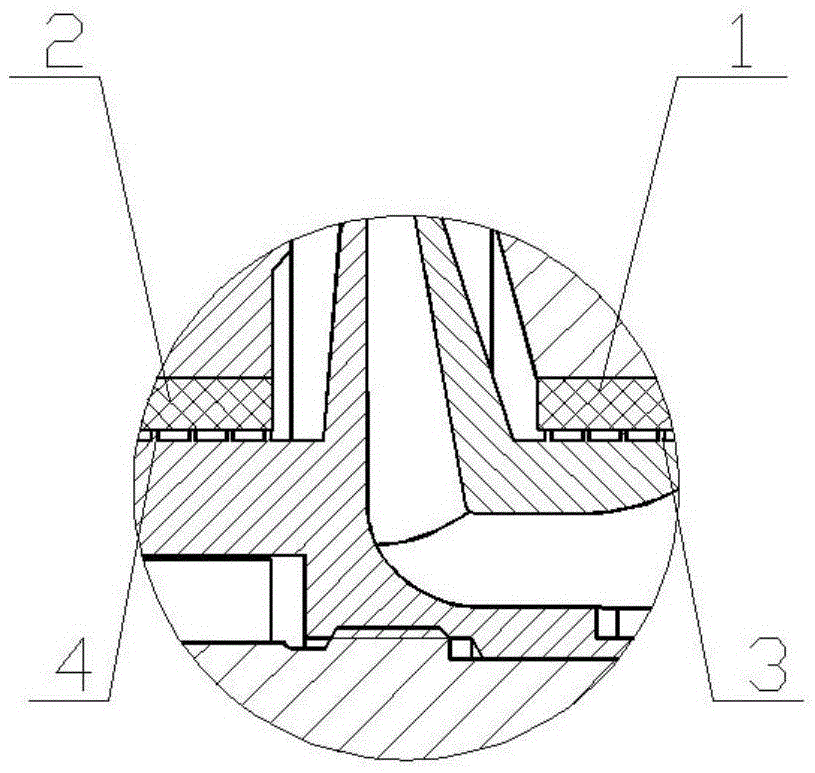

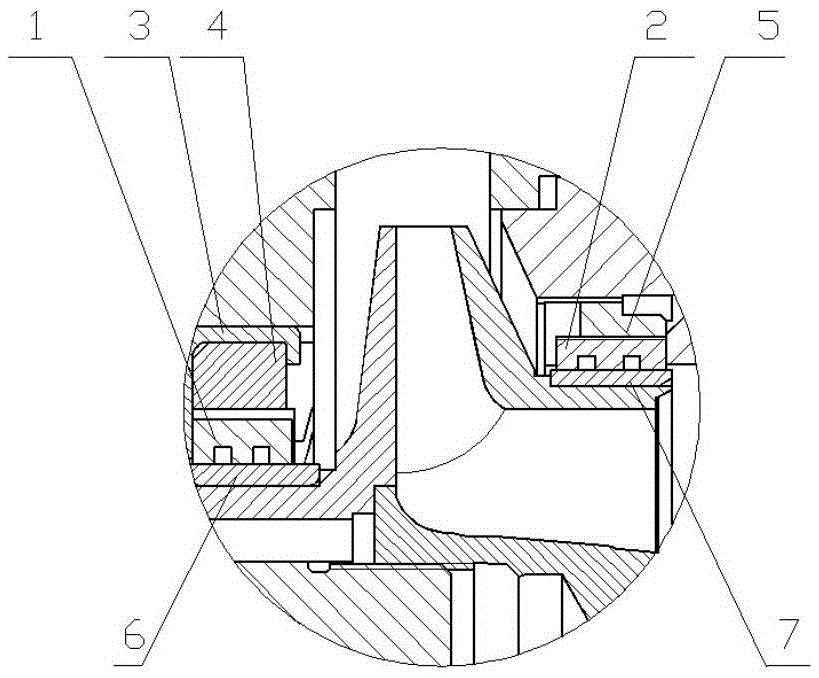

[0019] For the low specific speed centrifugal pump with small flow rate and high speed, its hydraulic efficiency is low under the ideal state. Therefore, in order to ensure the efficiency close to the ideal state, the influence of volume loss must be strictly controlled. Reducing the leakage gap before and after the centrifugal pump is the most direct means to improve the volumetric efficiency, but too small sealing gap will easily cause the pump running process, and the friction between the pump impeller and the sealing ring will occur under the action of the shafting beating, resulting in additional power consumption and fluctuations in working conditions. The invention solves the contradiction between improving the hydraulic efficiency and the friction between the pump wheel and the sealing ring under a small gap. The graphite sealing ring is embedded on the pump casing, and the sealing teeth are respectively processed on the front boss and the rear boss of the centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com