Metallization method for solar cell fabrication

A solar cell and metallization technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of low cost, reduced production cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

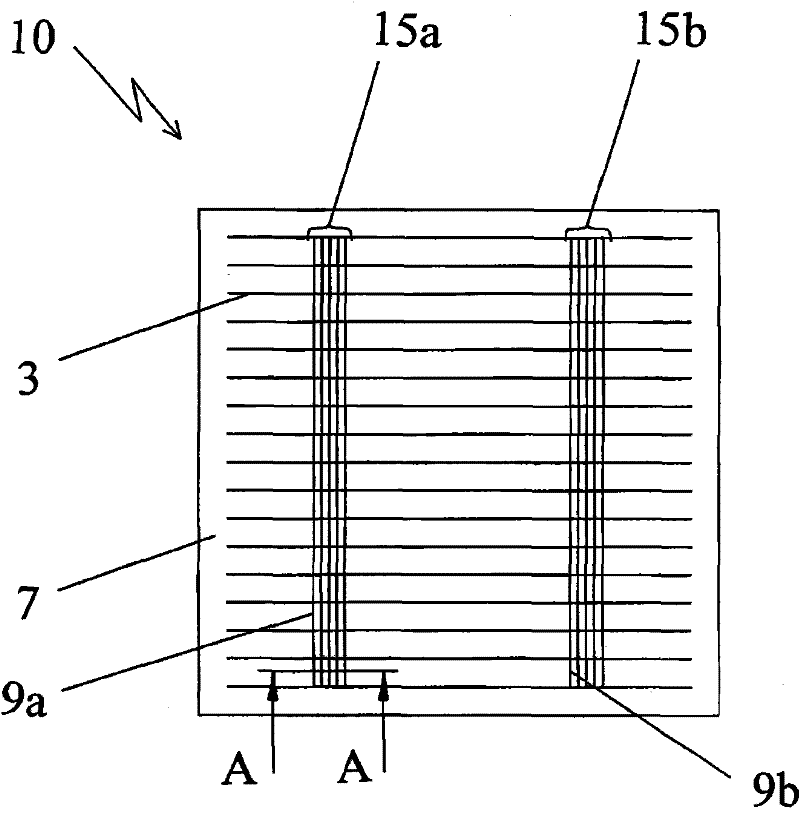

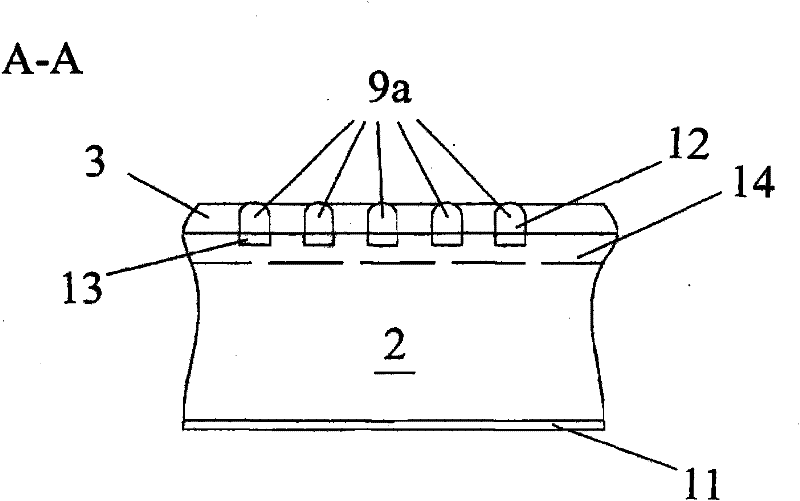

[0051] Such as figure 2 Shown is a schematic diagram of a first embodiment of a solar cell 10 of the present invention. The solar cell 10 has an electrode network comprising electrode metal fingers 3 and bus bars 15a, 15b. The bus bars 15a, 15b respectively include a plurality of bus bar metal fingers 9a, 9b arranged at intervals. Each bus bar 15a, 15b respectively includes bus bar metal fingers 9a, 9b which are locally gathered and arranged at intervals.

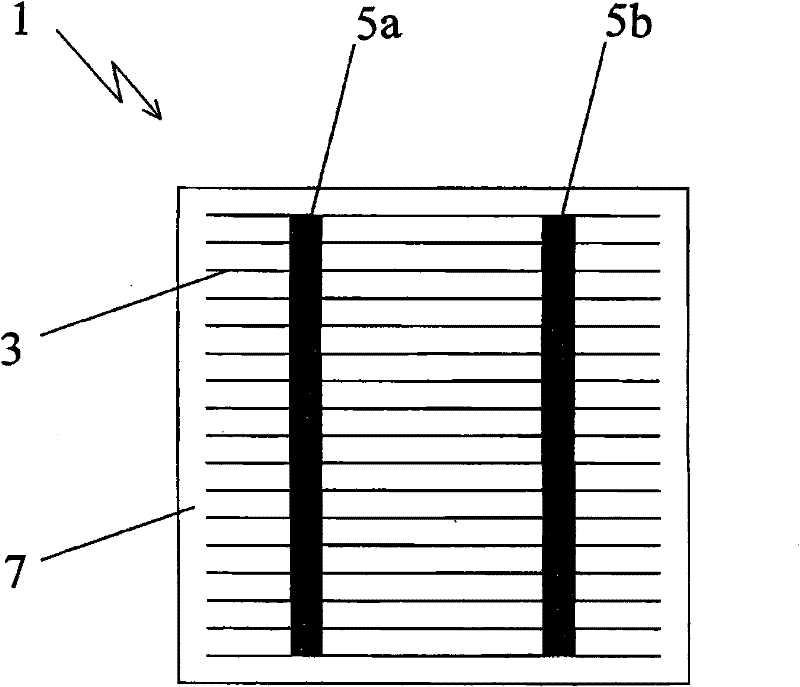

[0052] and figure 1 Compared with the shown prior art solar cell with electrode mesh, according to figure 2 An advantage of the solar cell of the present invention of the embodiment is that the solar cell produced has less shading of the active solar cell surface 7 . In this embodiment, the less shielding is mainly due to the fact that the bus bars 15a, 15b are respectively formed by the bus bar metal fingers 9a, 9b which are spaced apart from each other. As mentioned above, this less shadowing does not degrade fill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com