Universal type air-conditioner cable core end stamping, stripping and welding all-in-one machine

A cable and general-purpose technology, which is applied in the field of general-purpose air-conditioning cable core and wire end punching and stripping all-in-one machine, which can solve the problems of loose wire ends, broken wire cores, and the failure of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

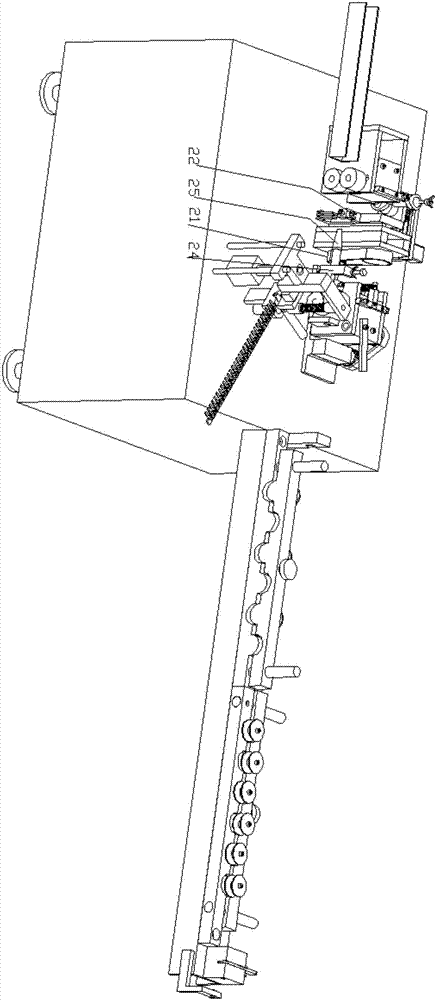

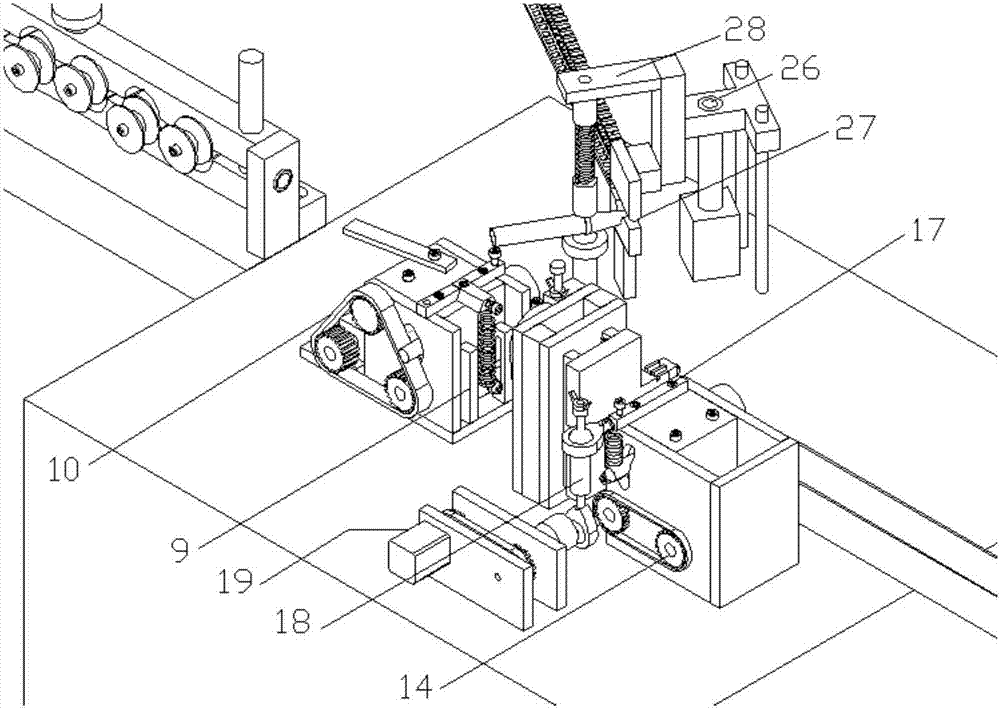

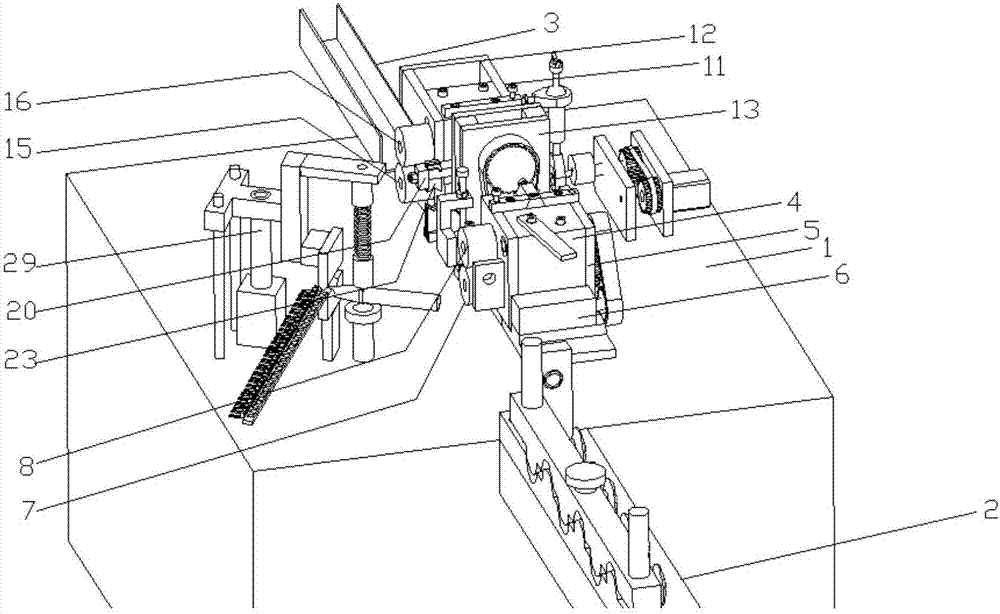

[0022] As shown in the attached figure, the general-purpose air-conditioning cable core and wire end stamping and stripping welding integrated machine includes machine 1, feeding assembly 2, and discharging assembly 3, and its feeding assembly 2 and discharging assembly 3 are separated from the machine. The left and right sides of 1 are fixed to the edge of machine 1 in a straight line, and its feeding component 2 is a vertical two-way staggered guide wheel structure, and a pressure relay 29 is arranged at the end, and its pressure relay 29 is located on the main circuit of machine 1 power supply Control the power on and off of machine 1; also include:

[0023] -Wire control component 4, its control line component 4 is fixed on the machine table 1 close to the feeding component 2 and is located at the connection position between the feeding component 2 and the discharging component 3, and its control line component 4 includes a wire controller body 5. The wire control motor 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com