A combed cotton web shearing device

A shearing device, combed cotton technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of poor cutting accuracy, fiber side slip, low work efficiency, etc., to achieve easy operation, accurate cutting length, High shearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

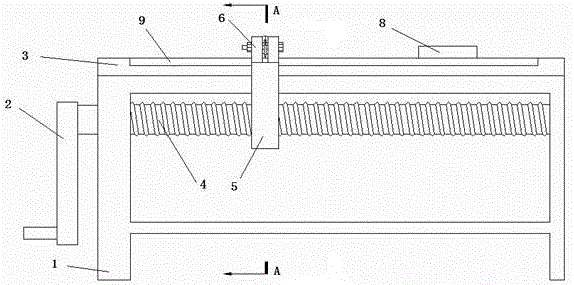

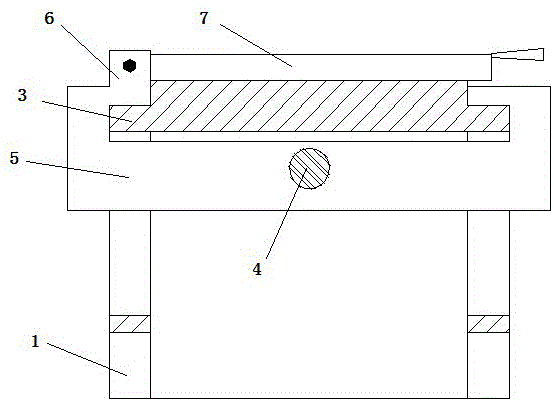

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] A combed cotton web shearing device, comprising a base 1, on which a stage 3 is arranged, and a lead screw 4 is arranged at the lower end of the stage 3, and one end of the lead screw 4 is fixedly connected with a driving handle 2, and the lead screw 4 is provided with a movable table 5, and the lead screw 4 and the movable table 5 are connected by a screw nut pair; the movable table 5 is fixedly provided with a blade control frame 6, and the blade control frame 6 is fixedly equipped with a blade 7; 3 is provided with scale 9.

[0015] The surface of the stage 3 is smooth. The stage 3 is provided with a scale 9, and the starting point of the scale 9 is used as the datum line of the cotton web head end. The stage 3 is provided with a fixing plate 8 for fixing the cotton net. The mobile platform 5 is fixedly provided with a blade control frame 6 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com