Oil-free piston, processing technology thereof and piston compressor

A processing technology and oil piston technology, applied in the field of air compressors, can solve the problems of prone to air holes, reduce the service life of pistons, burnout and condensation of lubricating oil, etc., and achieve the effect of accurate drilling position, high friction resistance and prevention of misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

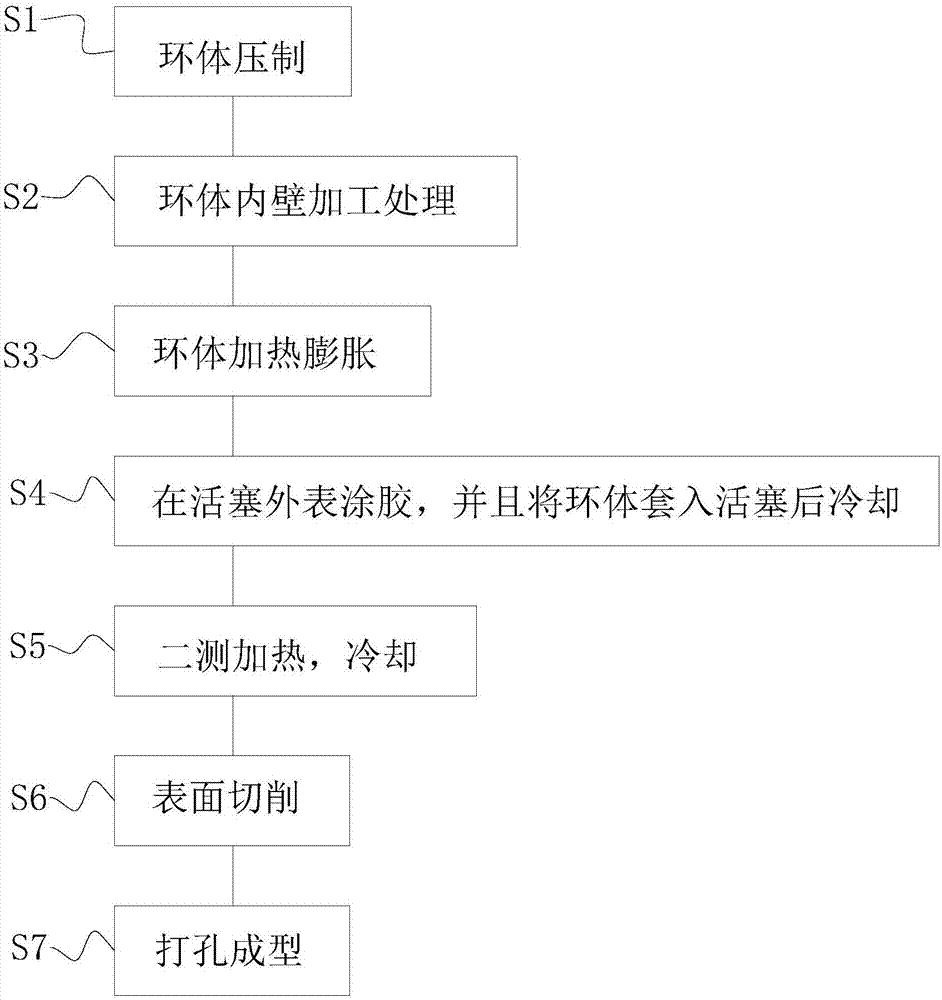

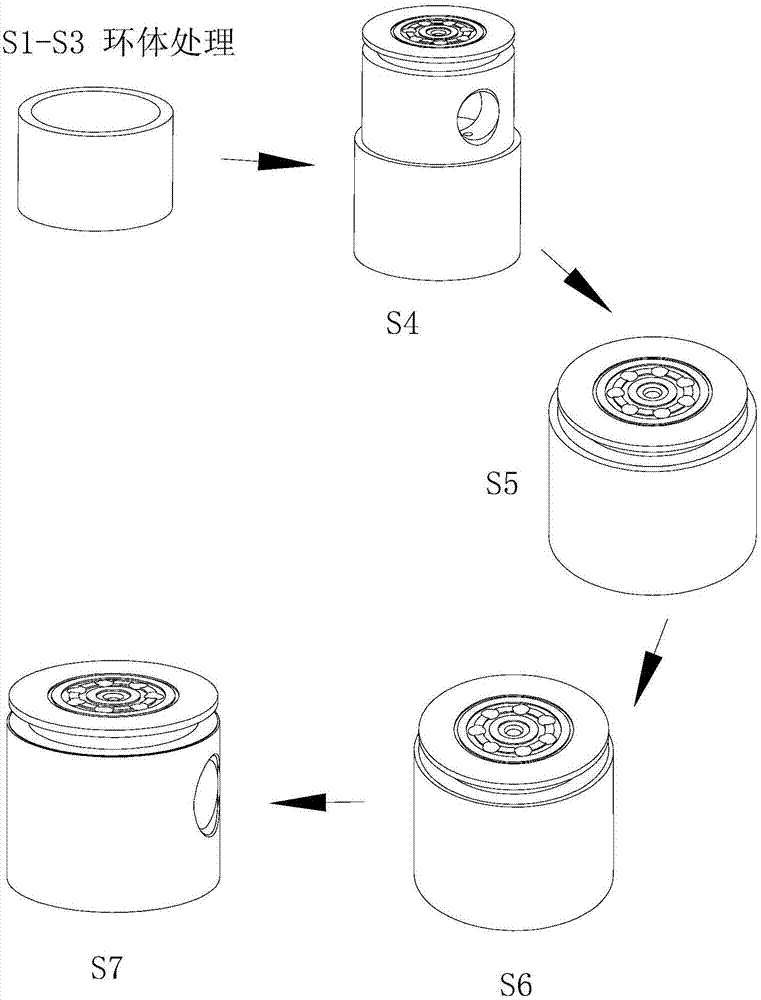

[0040] Embodiment 1: An oil-free piston machining process, including the following steps:

[0041] S1. The ring body compression of the self-lubricating piston sleeve;

[0042] S2, the inner wall of the ring is processed;

[0043] S3. Heat and expand the ring body;

[0044] S4. Apply glue on the outer surface of the piston, and cool the ring body after covering the outer surface of the piston;

[0045] S5. Reheat the entire cooled piston and then cool it;

[0046] S6. Cut the surface of the ring body so that its surface size can be sleeved with the cylinder block;

[0047] S7. Punching and forming, to open the ring body at the original pin hole (used to install the connecting rod pin) on the piston.

[0048] Among them, the ring body is made of polytetrafluoroethylene, glass fiber, molybdenum disulfide and copper powder, and the proportion is as follows:

[0049] PTFE 67 g

[0050] Glass fiber 3 g

[0051] Molybdenum disulfide 10 g

[0053] In S2, the inner wall of ...

Embodiment 2

[0057] Embodiment 2: A piston, which is manufactured using the process described in Embodiment 1.

Embodiment 3

[0058] Embodiment 3: A piston compressor including the piston described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com