Plate stamping equipment

A stamping equipment and plate technology, which is applied in the field of sheet metal processing, can solve problems such as product scrapping, stamping position deviation, waste of materials, etc., and achieve the effects of material saving, accurate stamping position, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

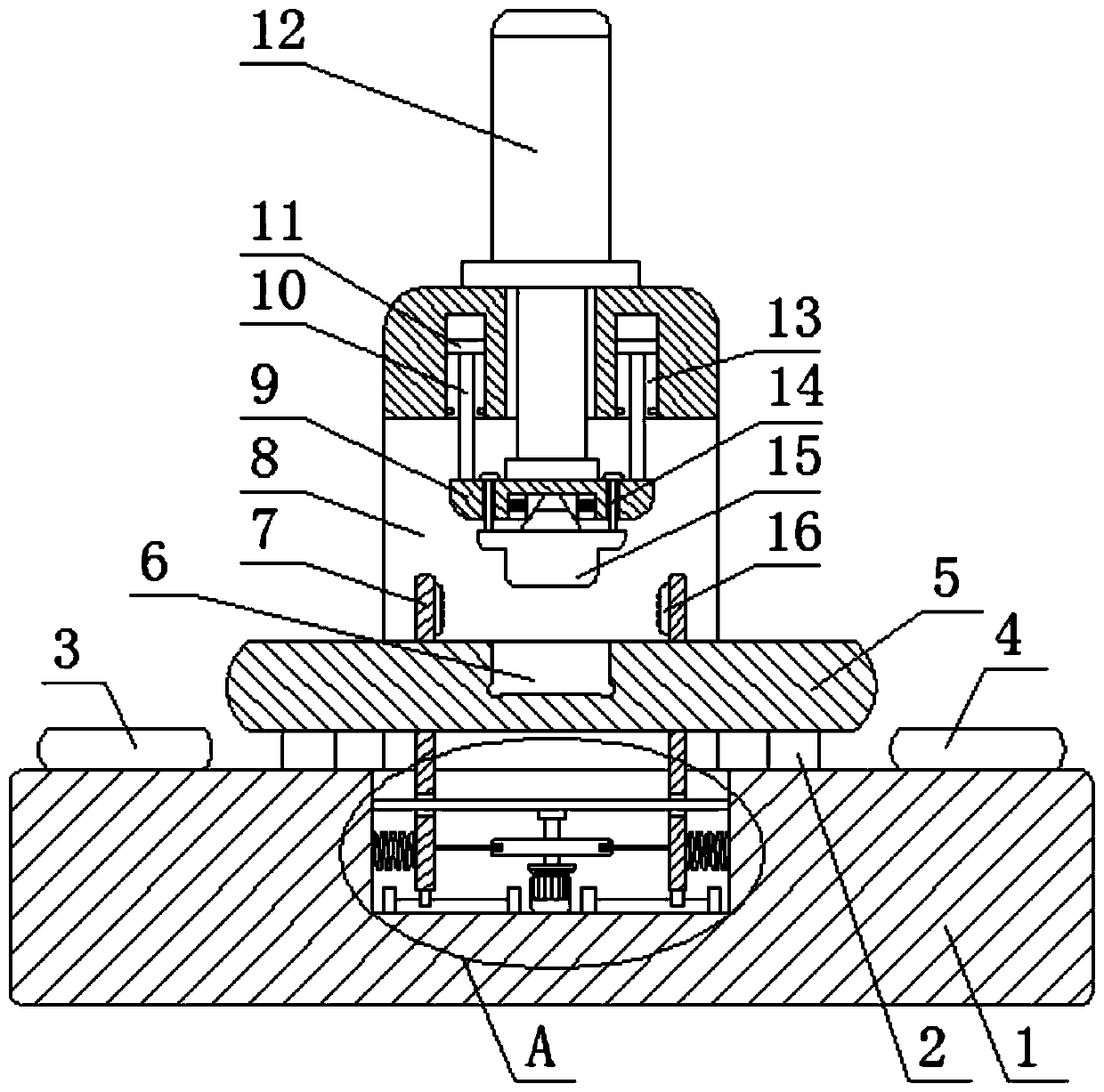

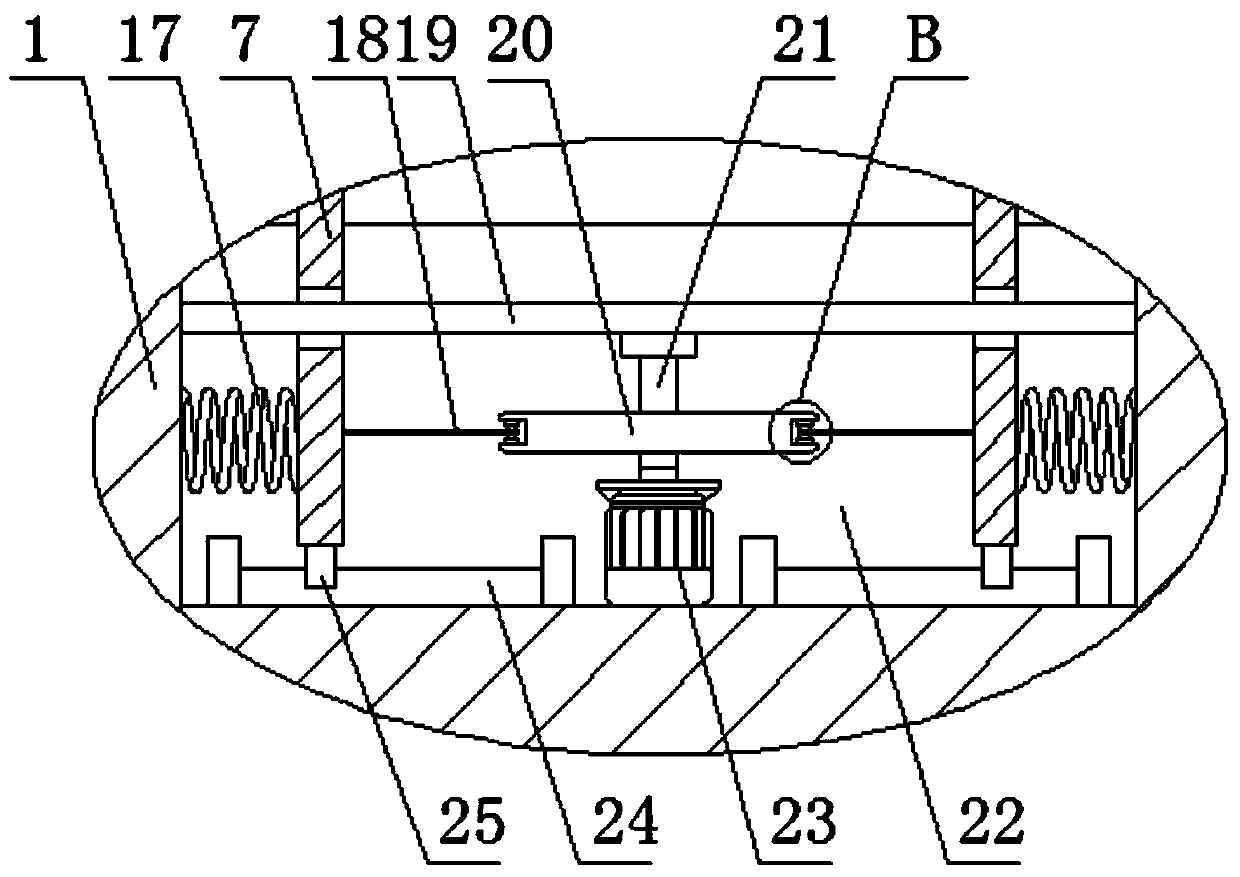

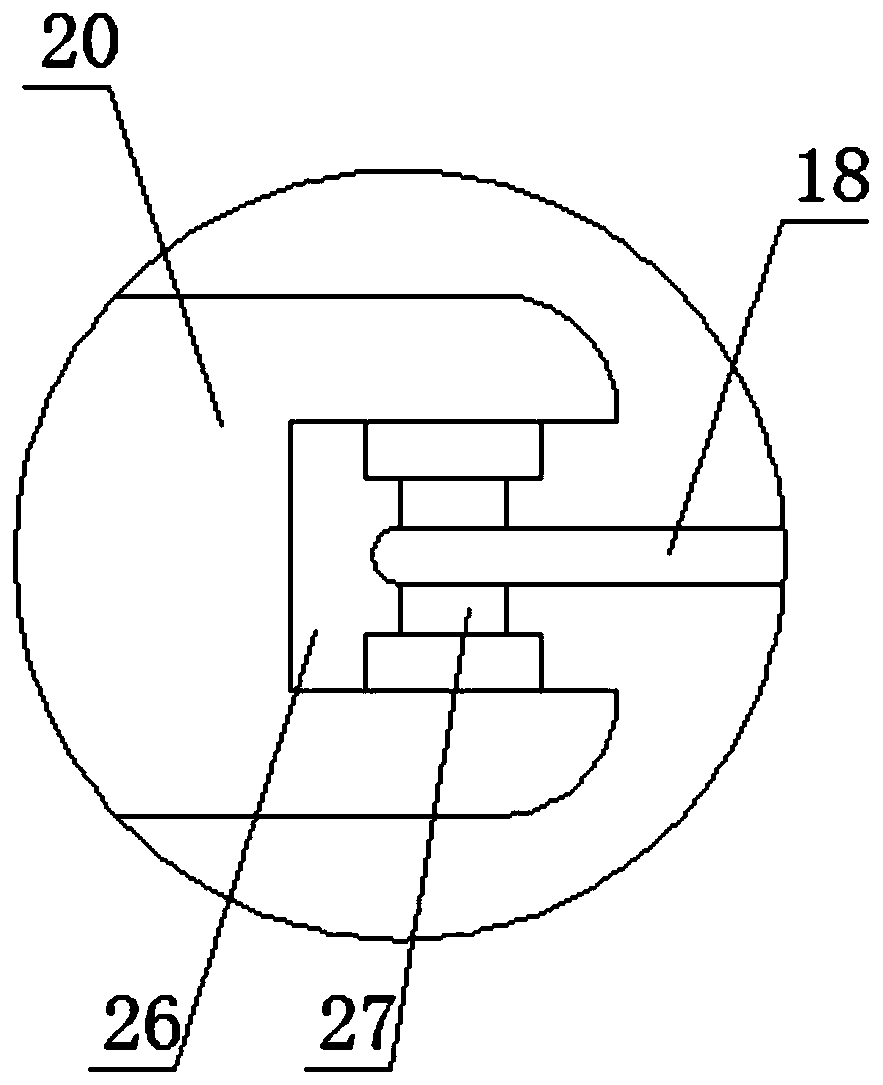

[0026] This embodiment proposes a plate punching equipment, including a base 1, a groove 22 is arranged at the center of the top of the base 1, a stamping table 5 is fixedly installed on the top of the base 1, the stamping table 5 is located above the groove 22, and the base The first U-shaped platform 3 and the second U-shaped platform 4 are respectively fixedly installed on both sides of the top of 1. The first U-shaped platform 3 and the second U-shaped platform 4 are respectively located on both sides of the punching platform 5. The first U-shaped platform A temperature sensor 33 is fixedly installed on the bottom inner wall of the 3 and the bottom inner wall of the second U-shaped table 4, and a punching groove 6 is arranged at the top center of the punching table 5, and two rectangular holes 34 are symmetrically arranged on the punching table 5, Two rectangular holes 34 are located on both sides of the stamping groove 6 respectively. The same slide bar 19 is welded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com