Ultrasonic metal pushing device

A punching device and ultrasonic technology, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of manual manual fixing of metal parts, difficult separation of metal parts and waste parts, etc., and reduce labor intensity and operation steps. The effect of reducing labor intensity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

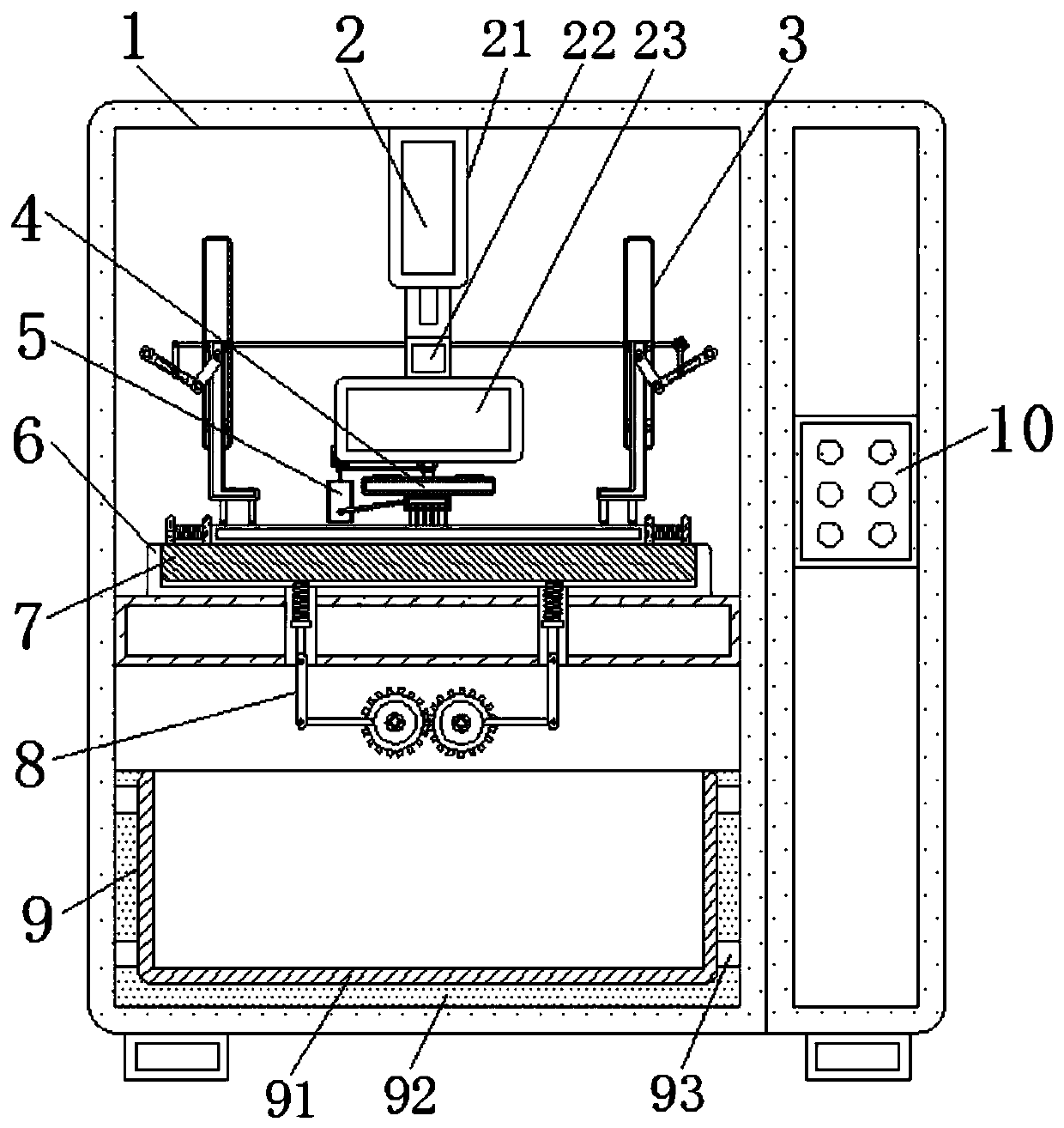

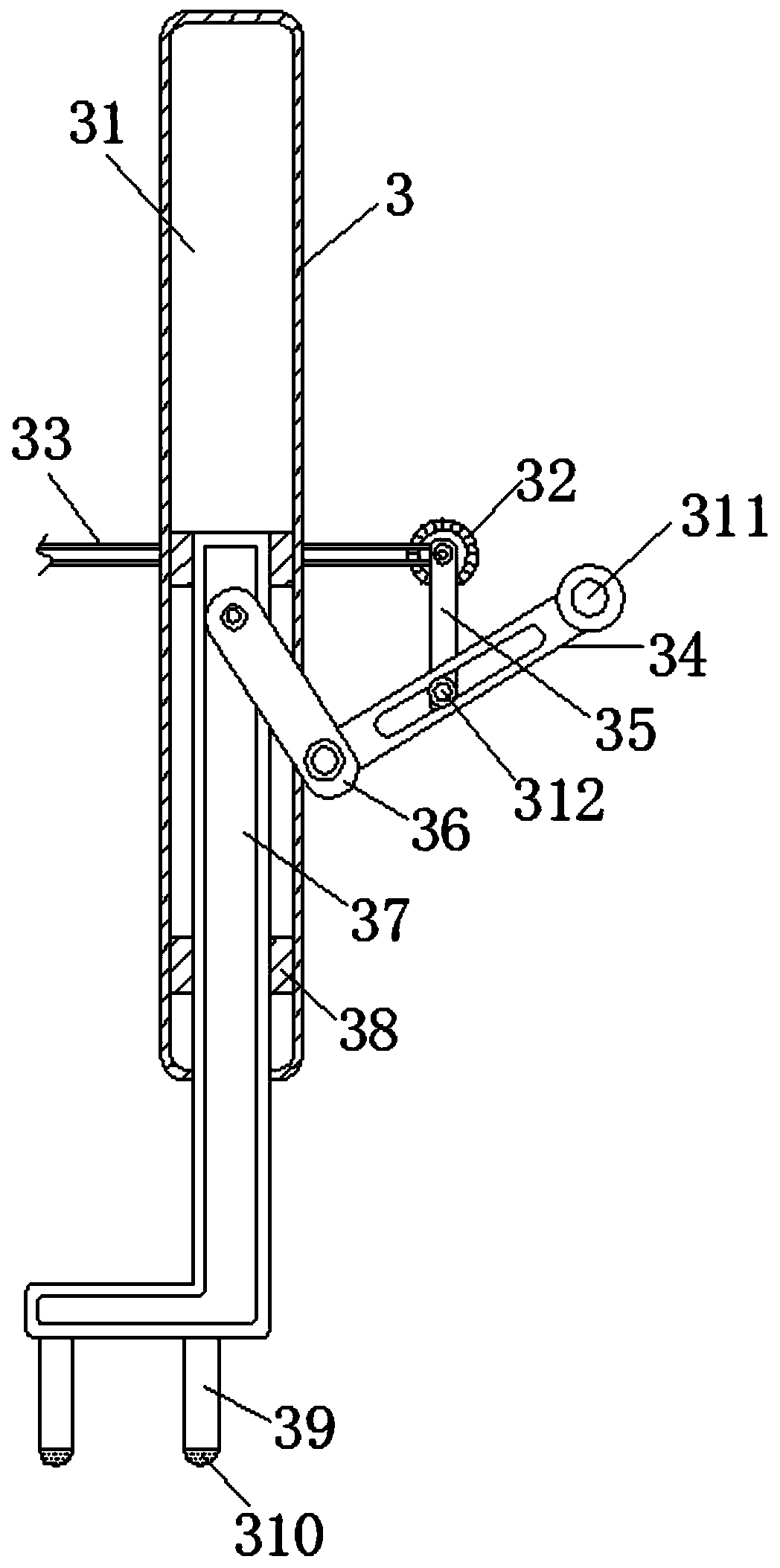

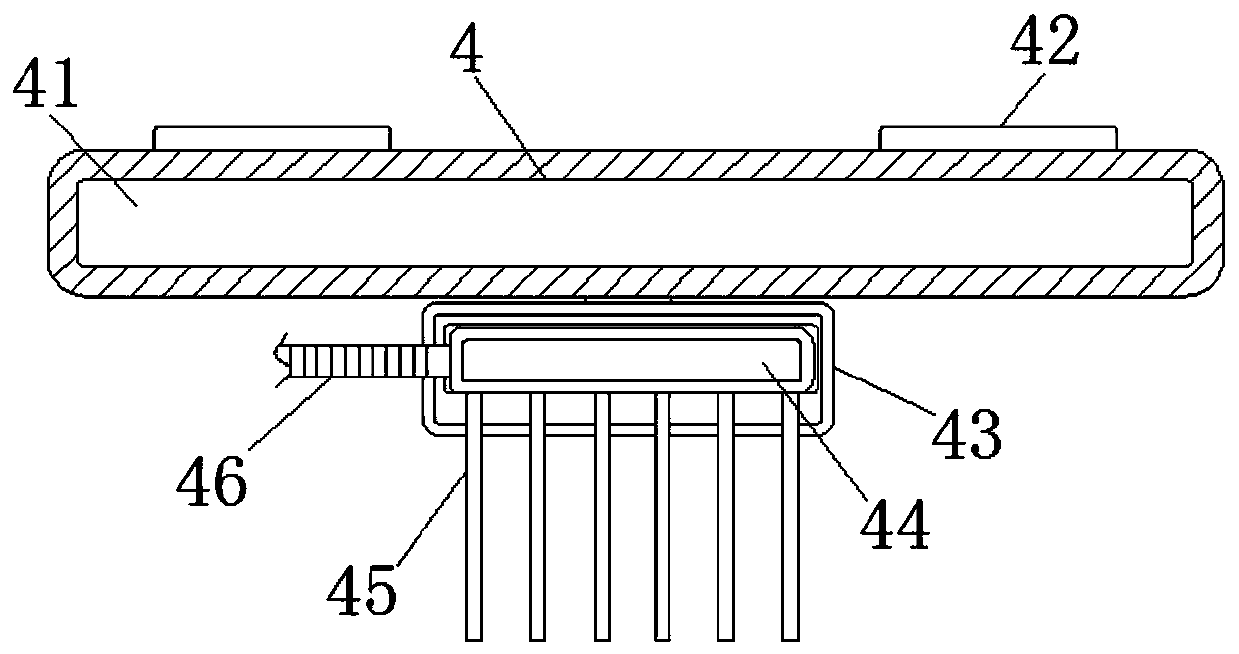

[0029]An ultrasonic metal punching device, comprising a device box 1, a punching mechanism 2 is fixedly installed at the inner center of the device box 1, and the punching mechanism 2 includes a hydraulic lifting rod 21, an ultrasonic transducer 22 and an ultrasonic punch 23. An ultrasonic transducer 22 is fixedly connected to the bottom end of the hydraulic lifting rod 21, and an ultrasonic punch 23 is installed on the bottom end of the ultrasonic transducer 22, and a separation mechanism 4 is installed on the back of the bottom end of the punching mechanism 2, and the separation mechanism 4 includes a fixed ring 41, a fixed rod 42, a sixth connecting rod 43, a telescopic rod 44, a brush 45, a hose 46, a first insertion rod 47, a fixed disc 48, a sleeve 49, a second insertion rod 410 and a limit rod 411, the surface of the fixed ring 41 is uniformly fixed with a fixed rod 42, and the bottom end of the fixed rod 42 is fixedly connected with a fixed disk 48, and the inside of th...

Embodiment 2

[0034] Embodiment 2: An ultrasonic metal punching device, including a device box 1, a punching mechanism 2 is fixedly installed at the inner center of the device box 1, and the punching mechanism 2 includes a hydraulic lifting rod 21 and an ultrasonic transducer 22 And ultrasonic punch 23, the bottom end of hydraulic lifting rod 21 is fixedly connected with ultrasonic transducer 22, and the bottom end of ultrasonic transducer 22 is equipped with ultrasonic punch 23, hydraulic lifting rod 21, ultrasonic transducer 22 and ultrasonic Punch 23 is prior art, and the bottom back of punching mechanism 2 is equipped with separating mechanism 4, and separating mechanism 4 comprises fixed ring 41, fixed rod 42, the 6th connecting rod 43, telescopic rod 44, brush 45, hose 46 , the first insertion rod 47, the fixed plate 48, the sleeve 49, the second insertion rod 410 and the limit rod 411, the surface of the fixed ring 41 is evenly fixed with the fixed rod 42, and the fixed rod 42 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com