Processing technology of modular cab

A processing technology, cab technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems that the modules are difficult to perfectly match, the space occupied by the cab is large, and the transportation cost is high, and the assembly is accurate, convenient and similar. The effect of high degree and precise punching position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

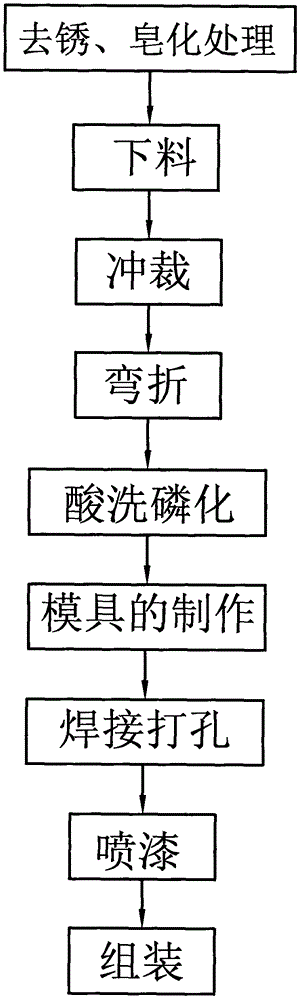

[0021] like figure 1 The processing technology of a modularized driver's cab shown includes the following steps:

[0022] A. Rust removal and saponification treatment: put the plate to be treated in an HCL solution with a concentration of 18-35% and pickle for 100-180 minutes to remove the scale on the outside of the plate; then take out the plate and put it in with a pH value of 3 Rinse in the aqueous solution of -7 for 1-2 minutes to remove the residual HCL solution on the surface of the board; then put the board into the oxalic acid solution with a concentration of 0.4-1% for 10-20 seconds to remove the spots on the surface of the board, and then take out the board and put it away Rinse in an aqueous solution with a pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com