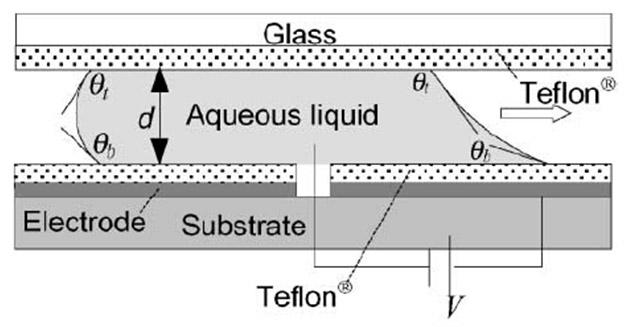

Electrochemical sensor chip based on digital microfluidic technology

A technology of sensor chips and digital microfluidics, applied in the field of microanalysis, can solve problems such as inability to realize chip integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

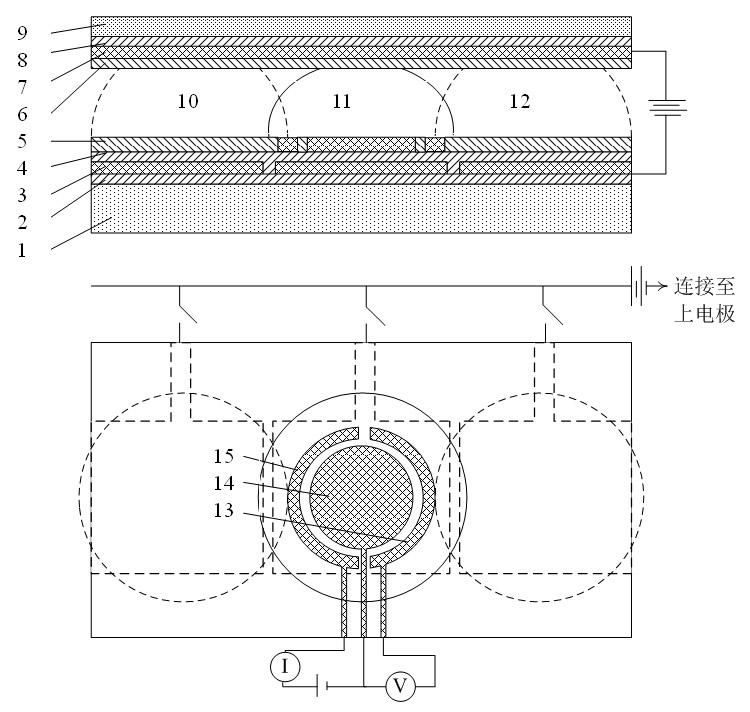

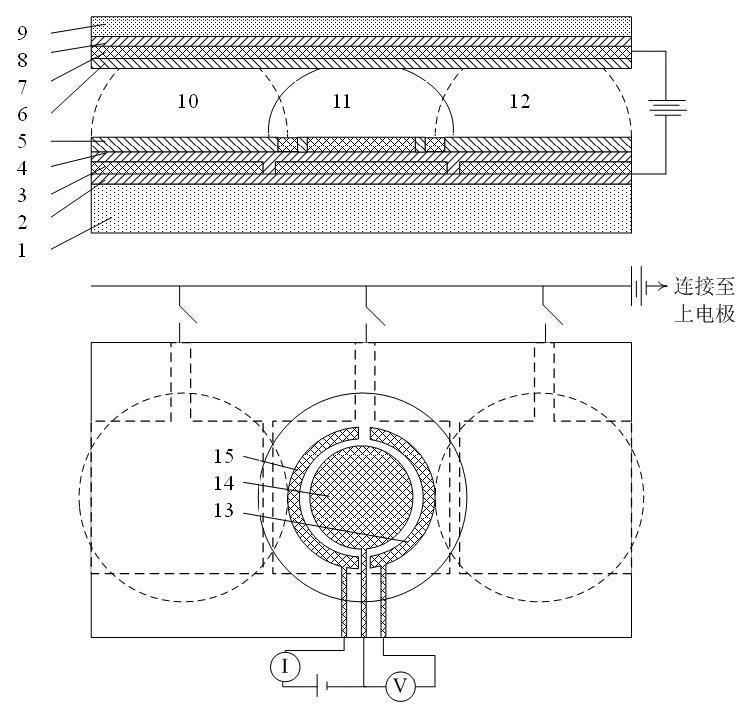

[0028] according to figure 2 Shown, the concrete implementation step of the present invention is as follows:

[0029] bottom layer

[0030] 1) Preparation of Substrate 1.

[0031] The substrate 1 can be any material, including a flexible substrate. If the substrate is a conductive material, an insulating layer 2 should be deposited first, and the process of depositing the insulating layer can be thermal oxidation, chemical vapor deposition CVD or physical vapor deposition PVD and other processes. For example, if the substrate is made of silicon, an insulating layer of silicon dioxide can be used.

[0032] 2) Deposition and patterning of the electrode layer 3 .

[0033] The electrode 3 can be metal, conductive polymer or conductive oxide, etc., and the electrode layer is deposited by spin coating annealing, physical sputtering or evaporation process. Patterning can use a) etching after photolithography (dry or wet), or lift-off process; b) hard mask combined with physical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com