Oily sewage treatment and treater thereof

A technology for treating process and oily sewage, applied in flotation water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low deoiling rate and complex process equipment in the first stage of air flotation and other problems, to achieve the effects of shortening the stirring process, high dissolution efficiency, and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Sewage treatment process and equipment

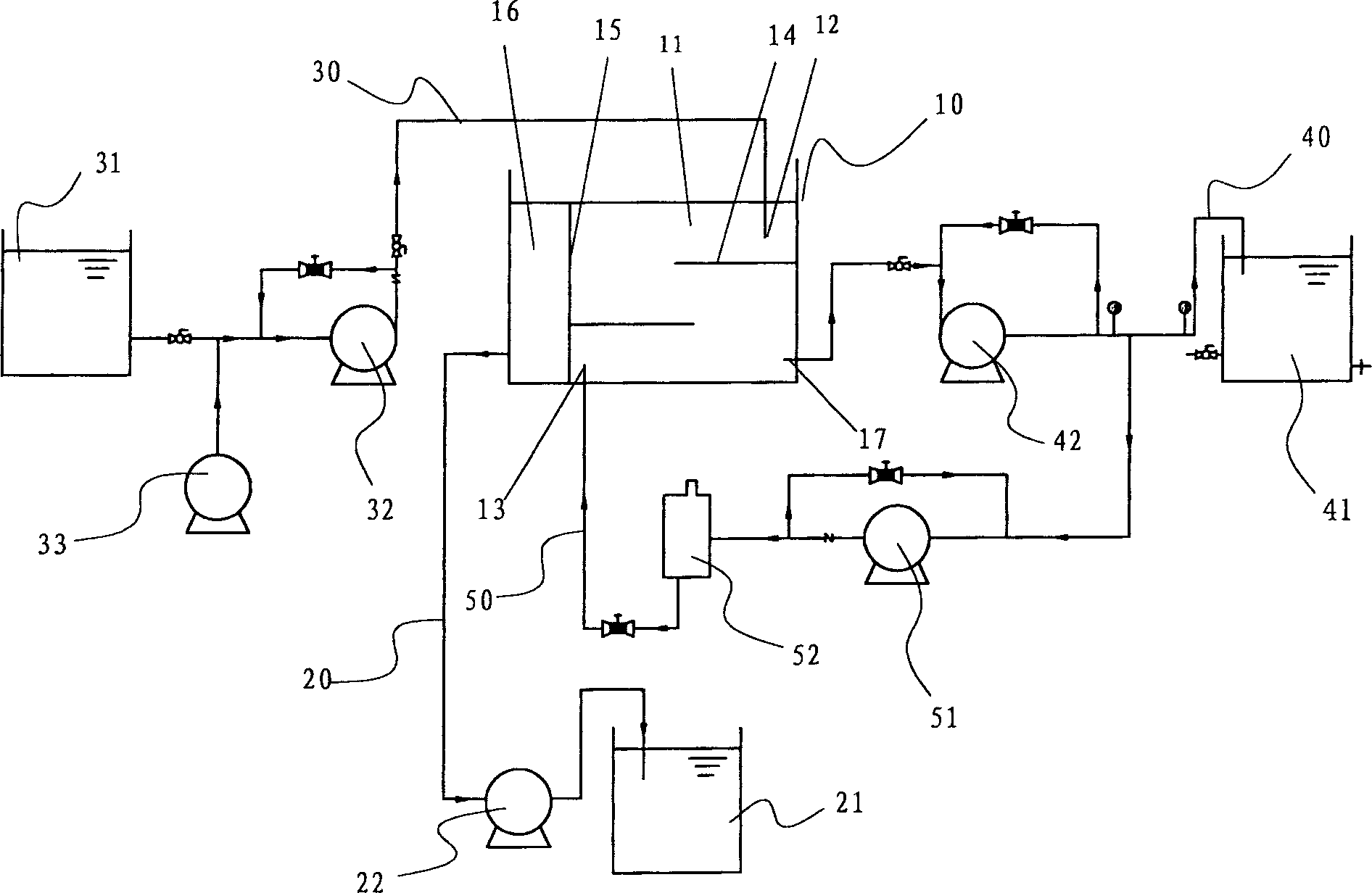

[0040] 1. Specific examples of air flotation treatment

[0041] Such as figure 1 with Figure 4 As shown, the air flotation device used in the present invention at least includes an air flotation reaction chamber 11 and a raw water inlet 12 and a dissolved air water inlet 13 connected to the air flotation reaction chamber 11, and the raw water inlet 12 is arranged on the air flotation reaction chamber 11. The upper part of the reaction chamber 11, and the dissolved air water inlet 13 is arranged at the lower part of the air flotation reaction chamber 11. In this way, in the air flotation reaction chamber 11, the raw water entering from the raw water inlet 12 flows from top to bottom, and the dissolved air water entering from the dissolved air water inlet 13 generates microbubbles from bottom to top after the pressure is released, so that the raw water Reverse contact with the micro-bubbles, the micro-bubbles can repeatedly col...

Embodiment 2

[0056] Using the high-efficiency dissolved air extended-range air flotation device of Example 1, the oily sewage is treated. Test conditions: pressurized dissolved air water 0.54MPa, the flow rate of the water inlet pump (raw water pump 32) is 600L / hour, the flow rate of the product water pump 42 is 1400L / hour, the flow rate of the air-water mixing pump 51 is 800L / hour Hours, the amount of composite flocculant added is 50ppm, which is a composite of polyaluminum chloride and polyacrylamide, and the compounding ratio of the two is about 30:1.

[0057] The sewage to be treated (raw water) appears to be oily sewage, with no visibility, slight odor, low BOD and COD content, and high oil content.

[0058] The above-mentioned sewage from the raw water pool 31 is mixed with the flocculant and then pumped into the air flotation reaction tank 11 from the top water inlet 12 by the raw water pump 32, and the dissolved air water from the air-water mixing pump 51 is adjusted to a pressure ...

Embodiment 3

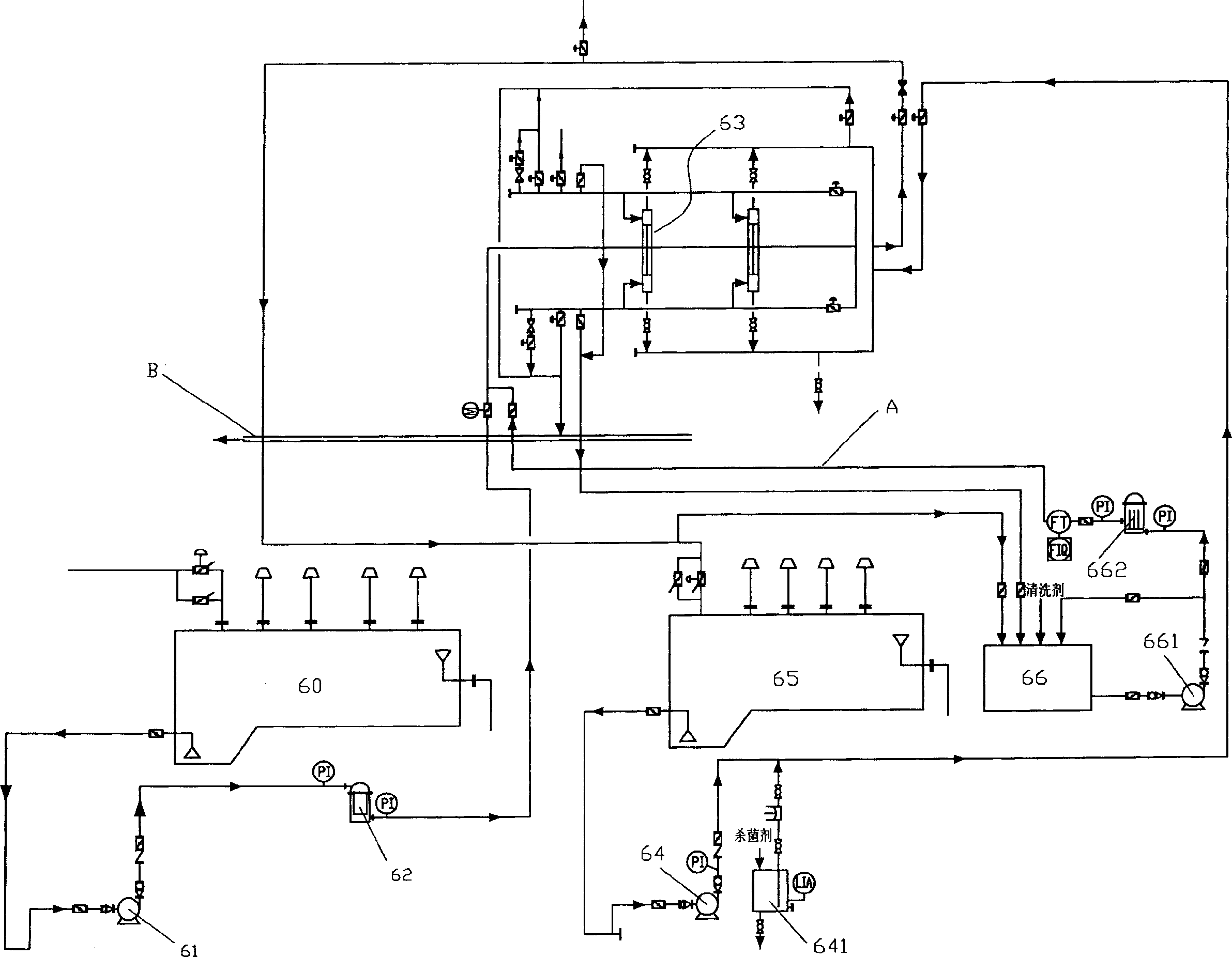

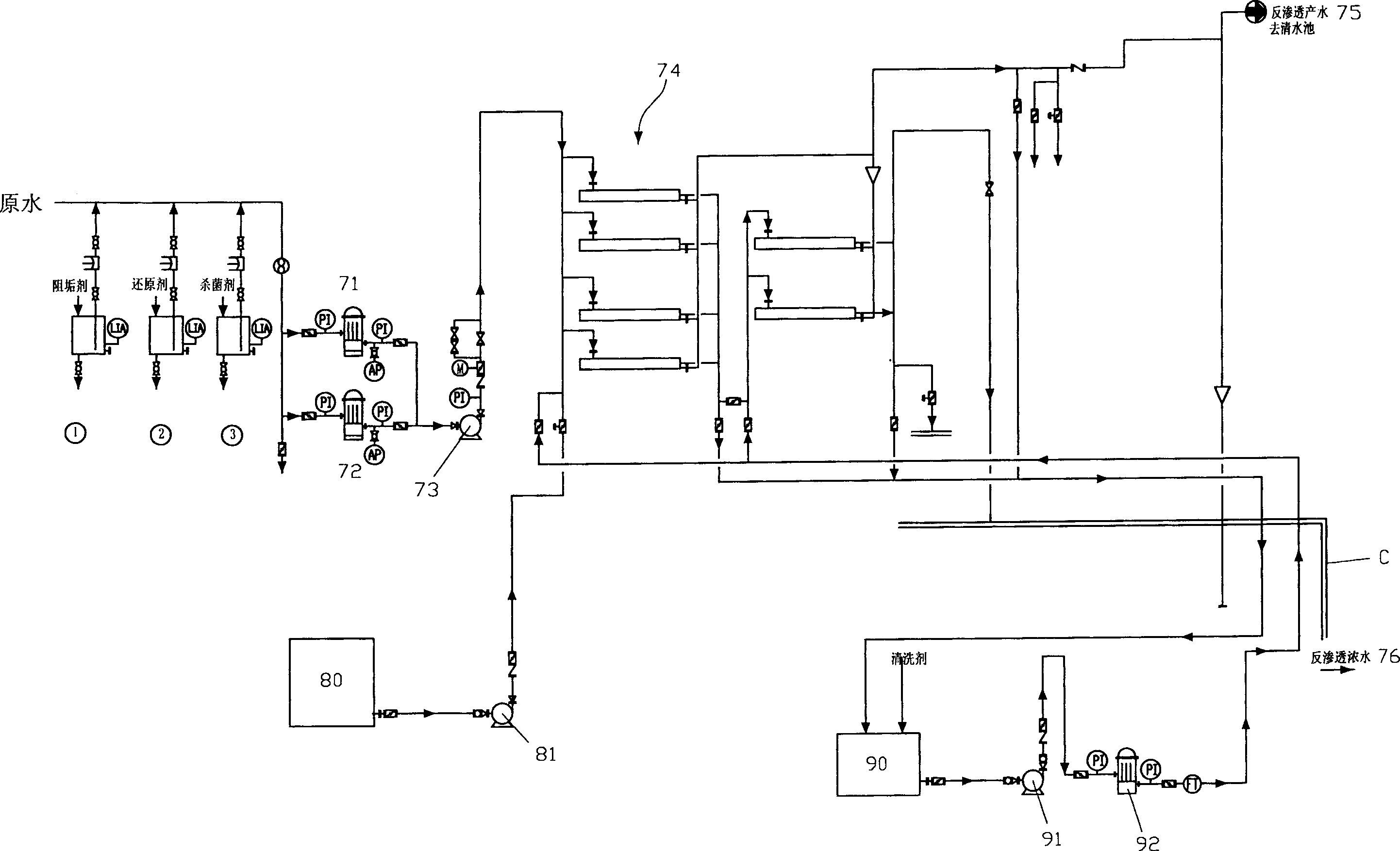

[0063] The air flotation water produced in Example 2 is sterilized by ozone oxidation and directly enters the ultrafiltration device of Example 1, and the treated water enters the reverse osmosis device of Example 1 for advanced purification treatment. The process is as described in Example 1.

[0064] Among them, the ultrafiltration membrane adopts Coriolis-V8048-35PMC, and the reverse osmosis equipment adopts BW4040 Dow membrane. During the treatment process, the ultrafiltration membrane adopts forward washing and backwashing, and the washing water volume is 10-12L / m 2 .s, backwash time 4min. The water quality indicators of the final product water are shown in Table 2:

[0065] Detection Indicator

[0066] It can be seen that the water treated by reverse osmosis is already high-quality water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com