Method for producing mung bean beverage containing full mung bean granules

A whole-granule, mung bean technology, applied in the application, food preparation, food science and other directions, can solve the problems of low utilization rate of mung bean, poor utilization of mung bean nutrients, etc., and achieve good taste and flavor, easy to chew, Complete and chewable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

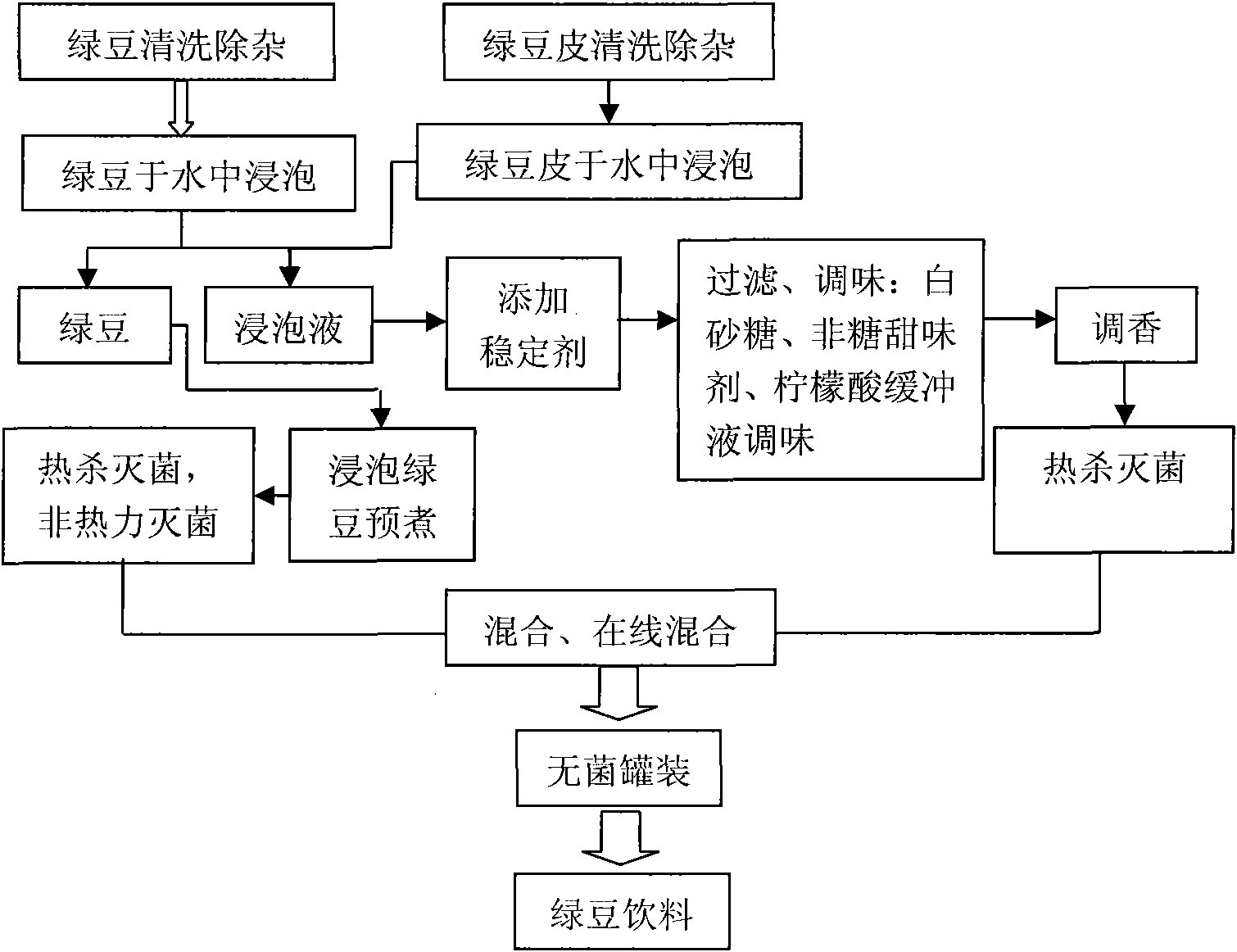

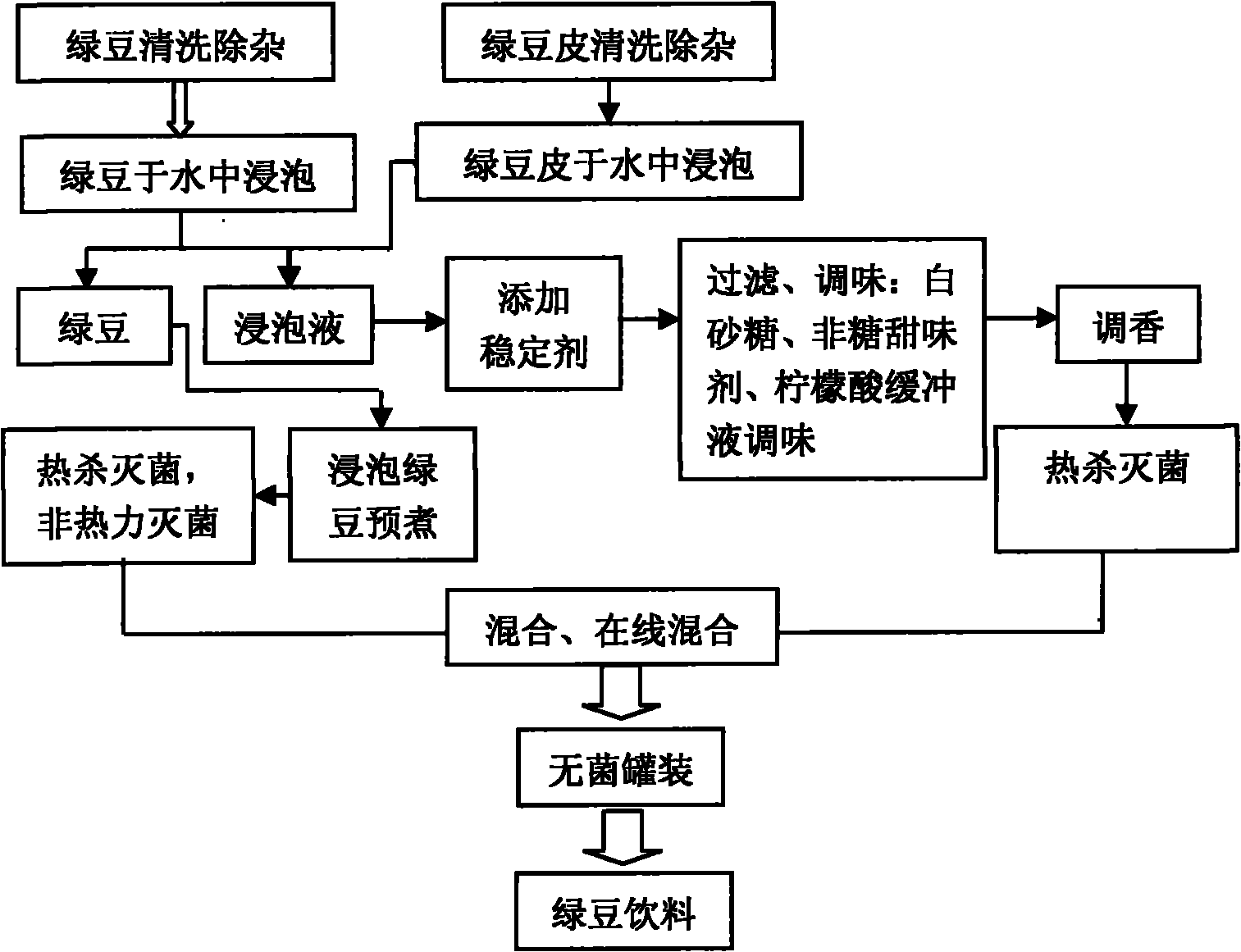

Image

Examples

Embodiment 1

[0028] A method for producing a mung bean beverage containing whole mung bean particles, the steps are as follows:

[0029] (1) Wash the mung beans with clean water, sort and remove the mung bean skins and clean them with clean water; wherein, the mung beans are mung beans that meet the edible standards, and have been manually or mechanically removed from impurities and shrunken, unusable particles; The mung bean skins are selected from clean mung bean skins that are separated from other food processing processes;

[0030] (2) Mix the cleaned mung beans with water at a mass-volume ratio of 1:20 (20ml of water is required for every 1g of mung beans), and soak them at room temperature at 25°C for 6 hours; 1:10 (add 10ml of water for every 1g of mung bean skin), mix and soak at room temperature 25°C for 6 hours;

[0031] (3) Separate the mung bean soaking liquid from the mung bean granules in step (2), separate the mung bean skin soaking liquid from the mung bean skin; mix the m...

Embodiment 2

[0041] A method for producing a mung bean beverage containing whole mung bean particles, the steps are as follows:

[0042] (1) Wash the mung beans with clean water, sort and remove the mung bean skins and clean them with clean water; wherein, the mung beans are mung beans that meet the edible standards, and have been manually or mechanically removed from impurities and shrunken, unusable particles; The mung bean skins are selected from clean mung bean skins that are separated from other food processing processes;

[0043] (2) Mix the cleaned mung beans with water in a mass-volume ratio of 1:20 (20ml of water is required for every 1g of mung beans), and soak for 6 hours at room temperature at 25°C; 1:10 (add 10ml of water for every 1g of mung bean skin), mix and soak at room temperature 25°C for 6 hours;

[0044] (3) Separate the mung bean soaking liquid from the mung bean granules in step (2), separate the mung bean skin soaking liquid from the mung bean skin; mix the mung b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com