Apparatus and method for generating micro bubbles

A micro-bubble generation and micro-bubble technology, applied in chemical instruments and methods, transportation and packaging, mixers, etc., can solve the problems of increased cost, large noise and vibration, difficult operation, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

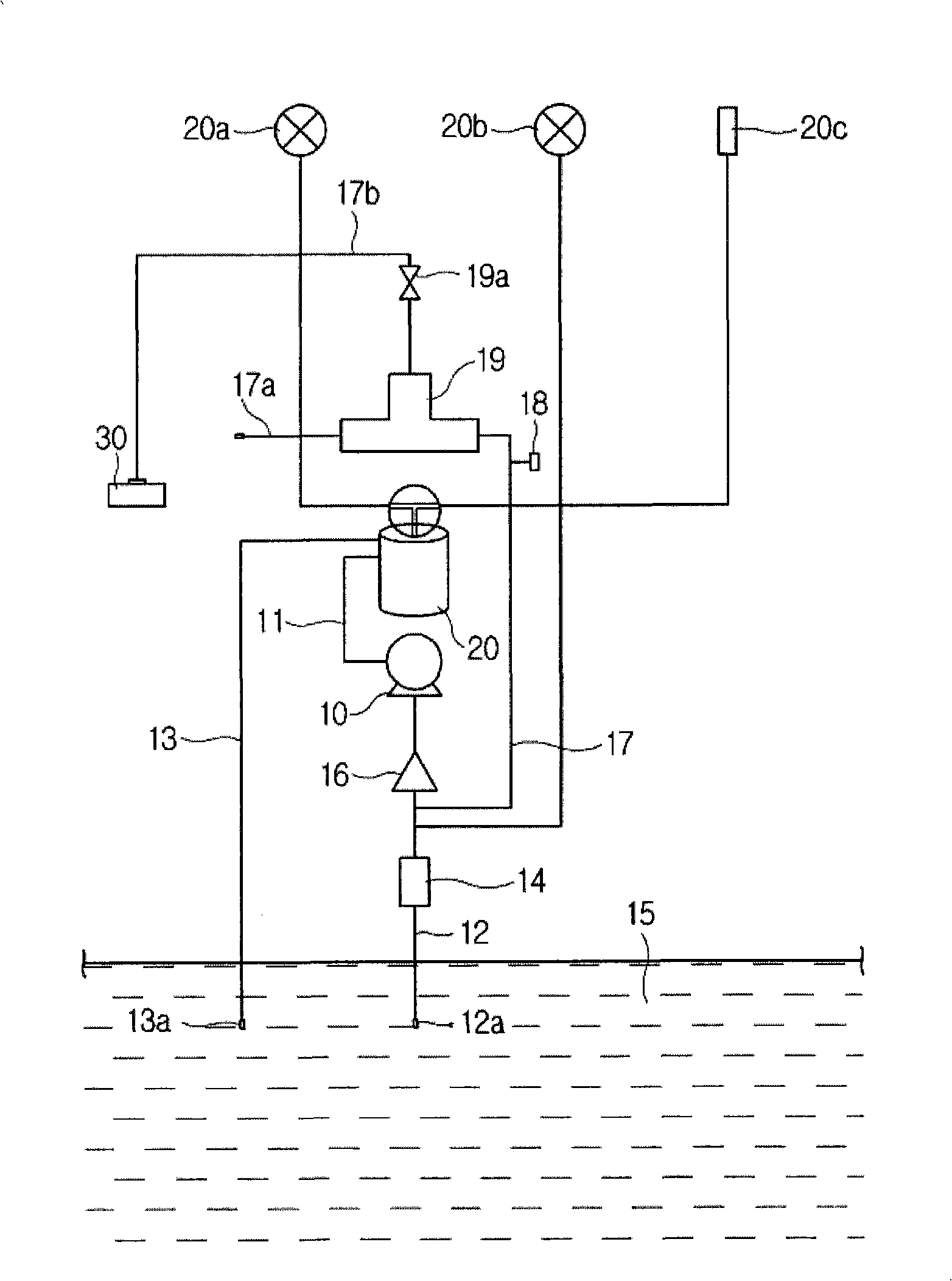

[0045] image 3 Shown is the schematic structure according to the micro-bubble generating device of the present invention, as shown in the figure, its basic structure of the micro-bubble generating device of the present invention is a pump 10 and corresponds to the above-mentioned figure 2 The pressurized tank 20 of the middle mixing chamber 3'.

[0046] The outlet of the pump 10 is connected to the inlet of the pressurized tank 20 through a pipe (water pipe) 11, and the inlet of the pump 10 and the outlet of the pressurized tank 20 lead to pipes (water pipes) 12, 13 extending into the water storage tank 15, respectively. .

[0047] In order to regulate the water flowing in from the water storage tank 15, the present invention is provided with a flow regulating valve 14 and a check valve 16 between the water inlet 12a of the water pipe 12 and the pump 10. And between the water inlet 12a of the above-mentioned water pipe 12 and the pump 10, a suction pipe 17 for sucking air ...

Embodiment 2

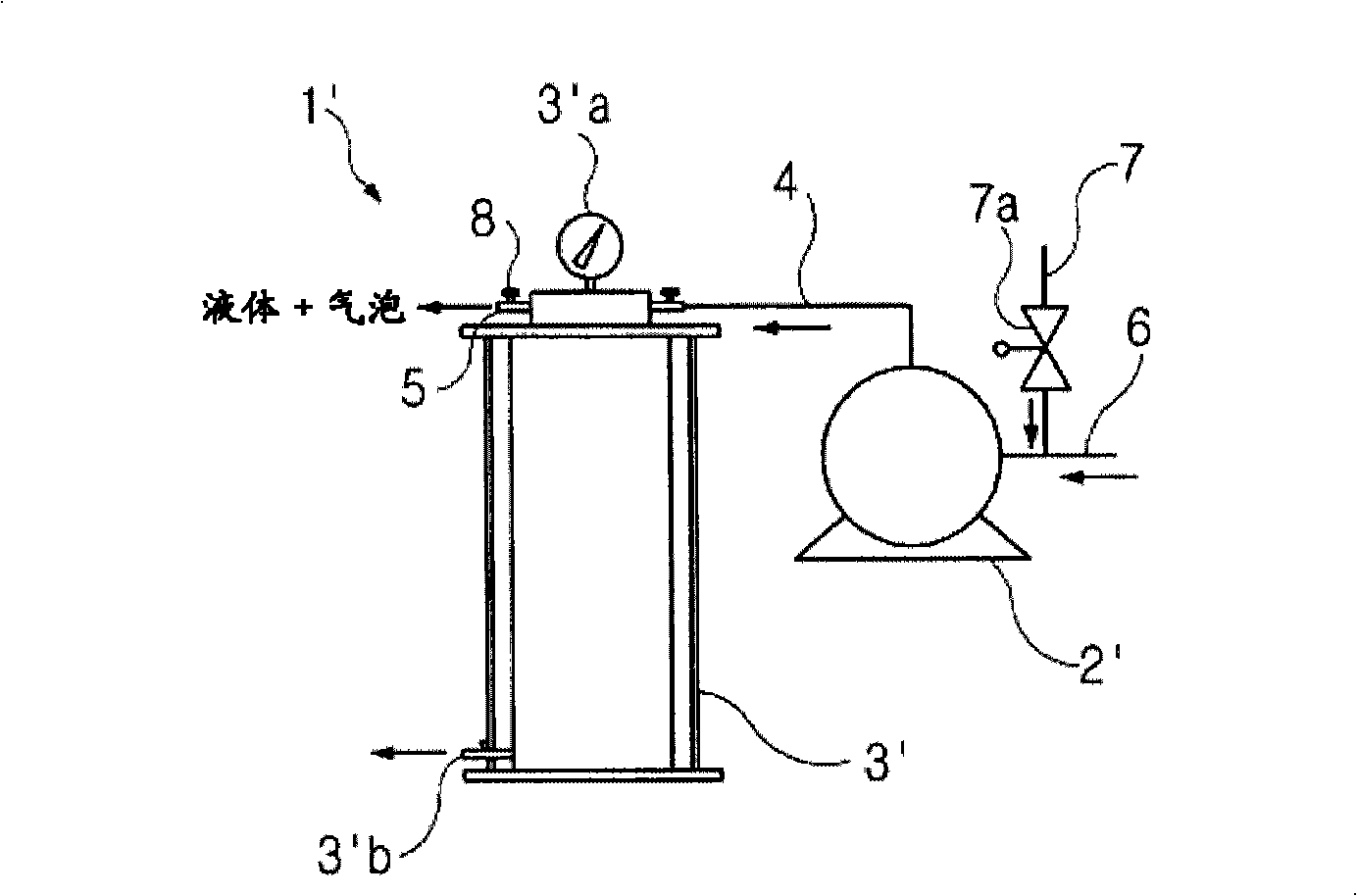

[0062] Figure 5 for image 3 A schematic diagram of a variant of the pressurized tank shown, Figure 6 for Figure 5 A cross-sectional view of the internal structure of the pressurized tank shown.

[0063] As shown in the figure, the pressurized tank 20' has a dual chamber structure of an inner chamber 27 and an outer chamber 28. The upper end of the outer chamber 28 is sealed, and the inner chamber 27 is separated from the inner wall of the outer chamber 28 and has an open upper end. The surface of the external chamber 28 is provided with connections to the respective water pipes 11, 13 (refer to image 3 ) of the inlet 21' and outlet 22', the inlet 21' and the outlet 22' extend toward the inside of the pressurized tank 20' with pipes 20'a, 20'b.

[0064] Most suitably, the inflow pipe 20'a extending from the inflow port 21' extends to the bottom of the inner chamber 27, and the outflow pipe 20'b extending from the outflow port 22' passes through the gap between the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com