Section material product of continuous glass-fiber reinforced hard polyurethane microfoam and coextrusion forming process

A technology of rigid polyurethane and glass fiber yarn is applied in the field of glass fiber reinforced thermosetting composite materials, which can solve the problems of low strength and inability to use load-bearing structural parts, and achieve the effects of long service life, excellent mechanical properties, and improved cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

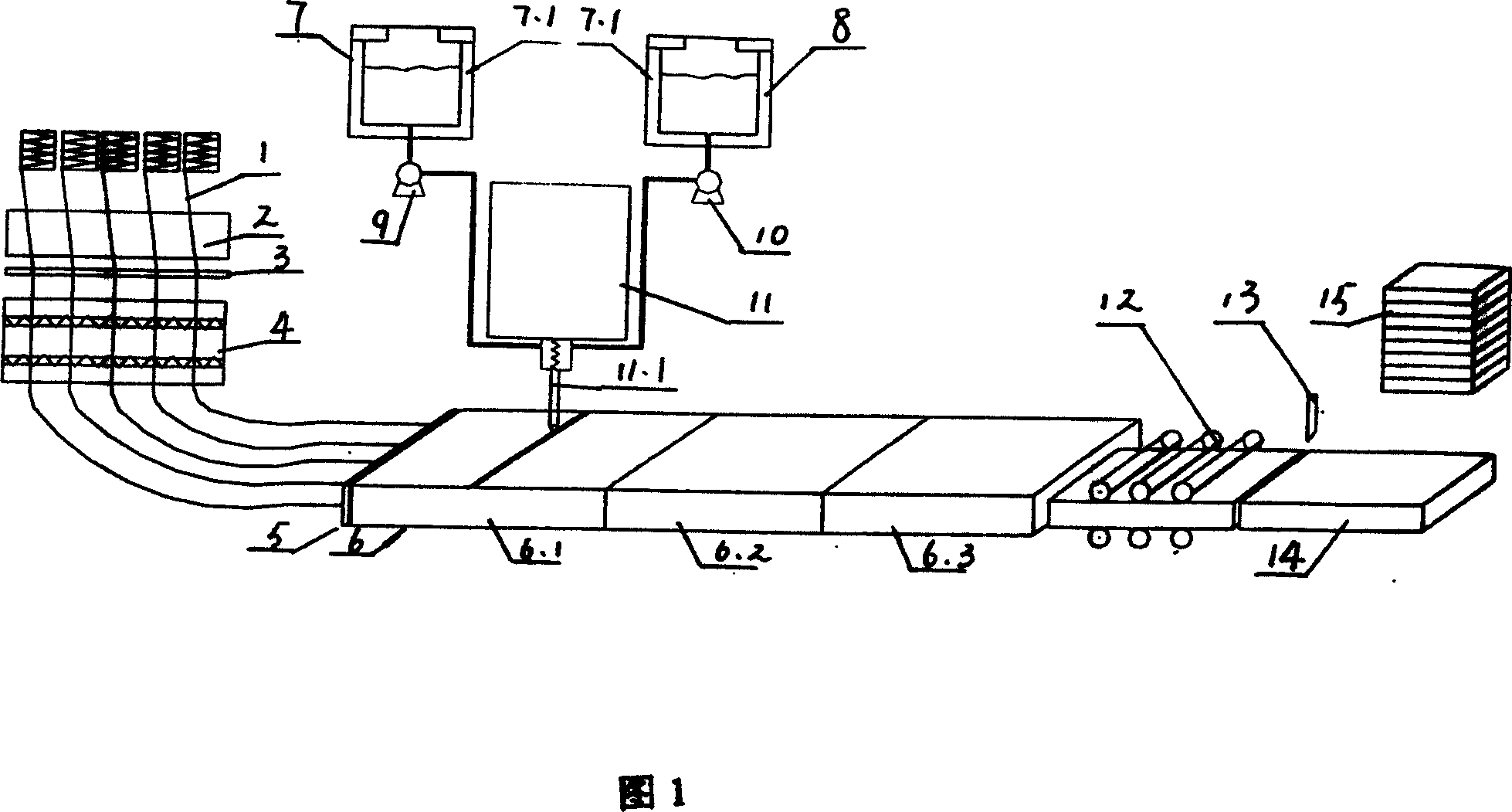

[0037] See Figure 1: Synthetic Sleeper

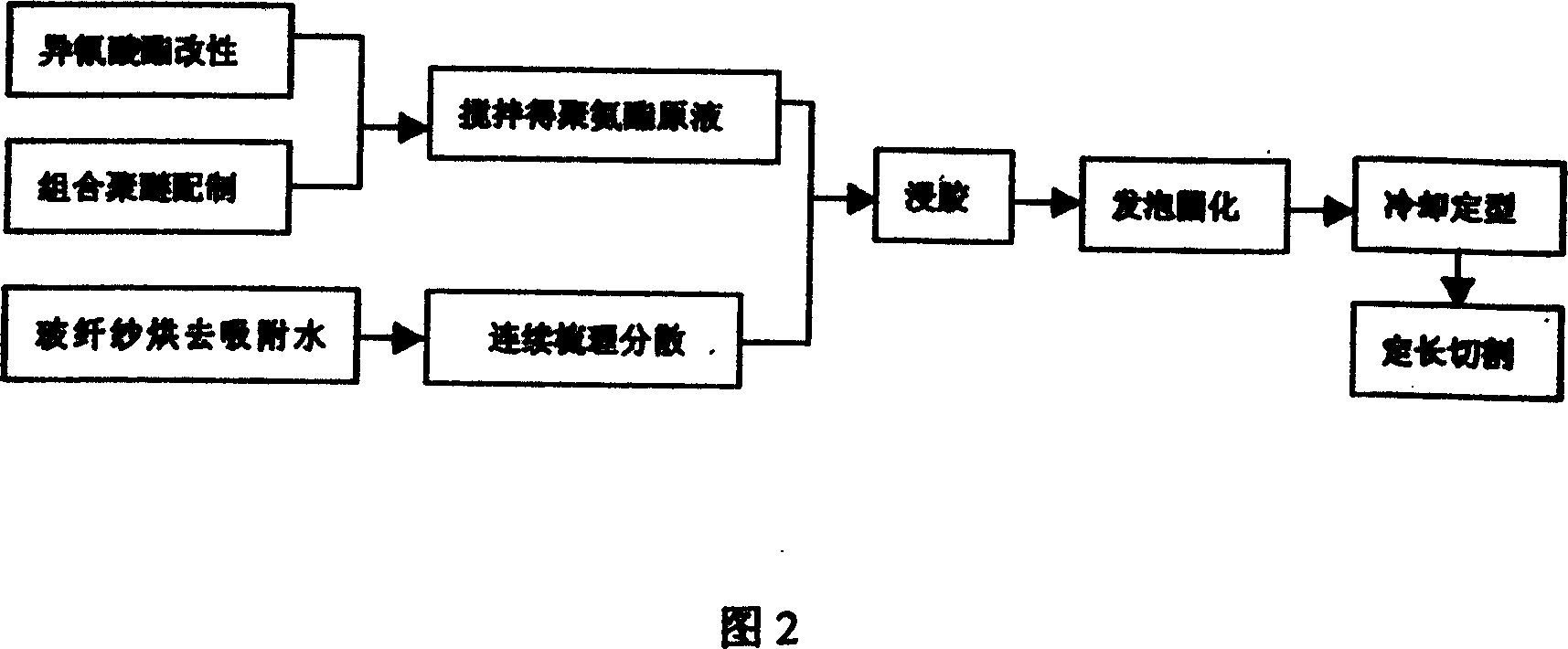

[0038] (1) Preparation of matrix material

[0039] The isocyanate is modified by adding 2.2% phosphorus and loaded into the storage tank.

[0040] Preparation of combined polyether: 100 parts of polyether

[0041] 0.3 parts of triethanolamine

[0042] Butyl stannous octoate 1.0 parts

[0043] Silicone oil 2 parts

[0044] Foaming spirit 2.5 parts

[0045] Anti-aging agent 0.2 parts

[0046] After accurately measuring according to the above formula, mix in the reactor for 1 hour, and then discharge and pack into cans.

[0047] The weight ratio of the modified isocyanate to the combined polyether is 1.05:1, which is set by the automatic metering system of the high-pressure foaming machine.

[0048](2) Reinforcing material: non-alkali non-twisted continuous glass fiber roving surface-treated with anilinomethyltrimethoxysilane coupling agent. The ratio of the...

Embodiment 2

[0059] Example 2: Container Siding

[0060] (1) Preparation of matrix materials

[0061] The formula for combining polyether: 100 parts of polyether

[0062] Triethylenediamine 0.8 part

[0063] Stannous octoate 1.0 parts

[0064] Silicone oil 2 parts

[0065] Foaming spirit 4.7 parts

[0066] Anti-aging agent 0.1 parts

[0067] Preparation and other reference examples 1

[0068] (2) Reinforcing material: refer to Example 1

[0069] (3) Product process: Referring to Example 1, the cross-sectional size is 1000×16.

[0070] (4) Main physical properties: product density 0.58g / cm 3 , glass fiber content 49%, bending strength 81Mpa, bending modulus 7930Mpa, impact strength 60KJ / m 2 .

[0071] The board has excellent mechanical properties, water and corrosion resistance, and dimensional stability. It is a lightweight structural composite material board that replaces steel with plastic and wood ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com