Method for strengthening separation effect of air floatation process by using micro-bubble modification technology

A technology of micro-bubbles and enhanced gas, applied in flotation water/sewage treatment, etc., can solve the problems of large dosage, long reaction time, complicated operation, etc., to reduce water content, increase adhesion probability, and improve separation and recovery efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

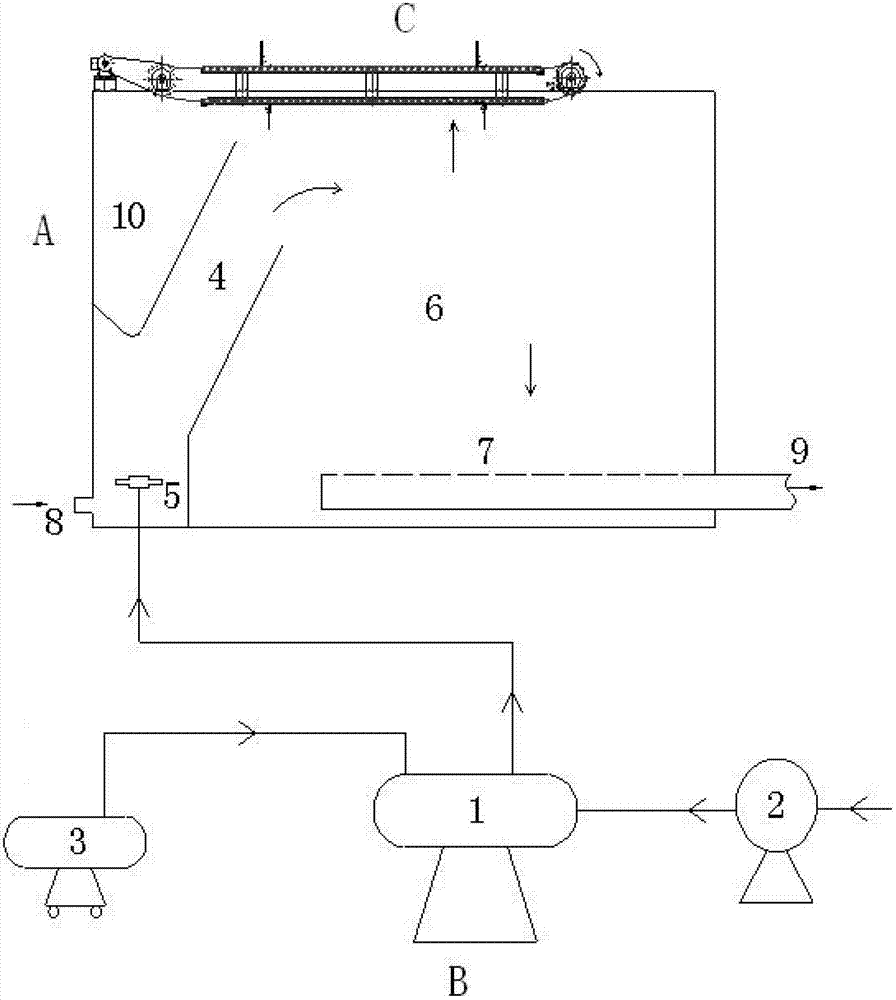

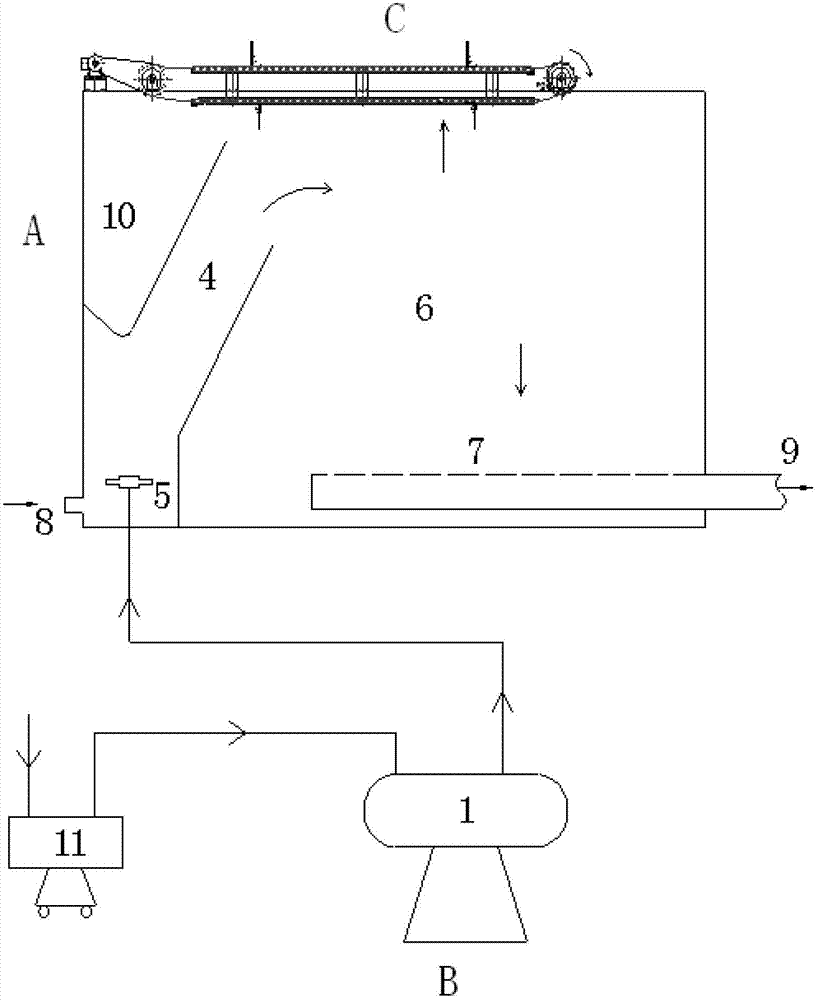

[0024] Specific implementation mode 1: In this implementation mode, the method of using microbubble modification technology to strengthen the separation effect of the air flotation process is specifically completed according to the following steps:

[0025] 1. Add the microbubble positive charge modifying agent to the microbubble generating system B of the air flotation system, the microbubble positive charge modifying agent is mixed with water and air source evenly, and supersaturation is formed in the pressure dissolved air tank 1 Dissolved air water, in which, the dosage of microbubble positive charge modifier is 0.1mg / L~30mg / L, the pressure in the pressure dissolved air tank 1 is maintained at 0.3MPa~0.6MPa, and the water in the supersaturated dissolved air water and The volume ratio of water to be treated is 5%~70%;

[0026] The air flotation system includes an air flotation tank body A, a microbubble generation system B and a scum collection system C. The microbubble gen...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the microbubble positive charge modifier is a metal coagulant, cationic surfactant, cationic polymer, chitosan or modified chitosan sugar derivatives. Others are the same as in the first embodiment.

[0033] In this embodiment, chitosan and modified chitosan derivatives are non-toxic and harmless, have better biocompatibility and biodegradability, and can be applied in the field of drinking water purification.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the metal coagulant is aluminum chloride, aluminum sulfate, ferrous sulfate, ferric sulfate, ferric chloride, polyferric chloride, polychlorinated One or more combinations of aluminum and polyaluminum sulfate. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com