Method for preparing cellulose ester by using cellulose

A cellulose ester and cellulose technology, applied in the field of cellulose ester production from cellulose, can solve the problems of high cost of purification and recycling, high cost of solvent, high cost of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

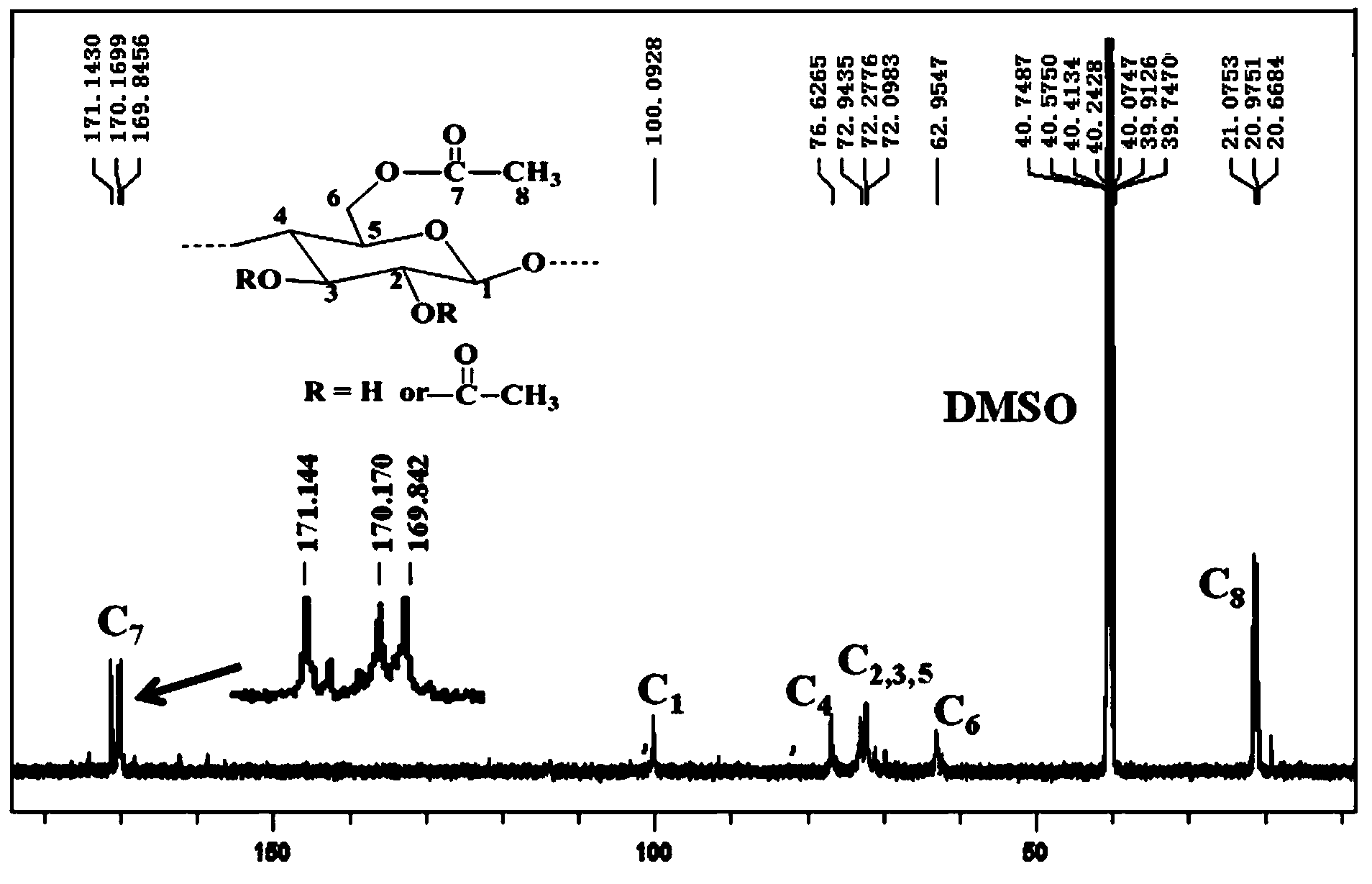

[0070] Weigh about 0.5g of corn stalk cellulose, and about 10g of a mixed solution composed of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), methanol and DMSO (DMSO accounts for The mole fraction of the solution is 80%, DMSO is about 5.8g, DBU is about 2.8g, methanol is about 0.59g), put them into the autoclave together, cover the autoclave, and pass 0.5MPa of CO 2 , the temperature is at 80°C, sealed and vigorously stirred mechanically for 1 hour, and a one-pot reaction is carried out to dissolve the cellulose. A clear and transparent cellulose solution was obtained, and the concentration of the cellulose solution was 5% (mass fraction). Keep the temperature at 80°C, and add acetic anhydride (about 2.86g) to the solution at the same time, so that the molar ratio of acetic anhydride to the total hydroxyl groups in the cellulose solution is 1:1, and react for 5h. After the reaction was completed, the product was precipitated with 3 times the amount of water, and the solid product ...

Embodiment 2

[0072] Efficient recycling of solvents is an important special feature of this patent, which we illustrate through this example.

[0073] Weigh 0.5g of microcrystalline cellulose, weigh about 10g of the mixed solution composed of DBU, methanol and DMSO (the molar fraction of DMSO in the mixed solution is 80%, about 5.8g of DMSO, about 2.8g of DBU, and about 0.59g of methanol), Add together in the autoclave, cover the autoclave, pass 0.5MPa of CO 2 , the temperature is at 80°C, sealed and vigorously stirred mechanically for 1 hour, and a one-pot reaction is carried out to dissolve the cellulose. A clear and transparent cellulose solution was obtained, and the concentration of the cellulose solution was 5% (mass fraction). Keep the temperature at 80°C, and add acetic anhydride (about 2.86g) to the solution at the same time, so that the molar ratio of acetic anhydride to the total hydroxyl groups in the cellulose solution is 1:1, and react for 5h. After the reaction was complet...

Embodiment 3

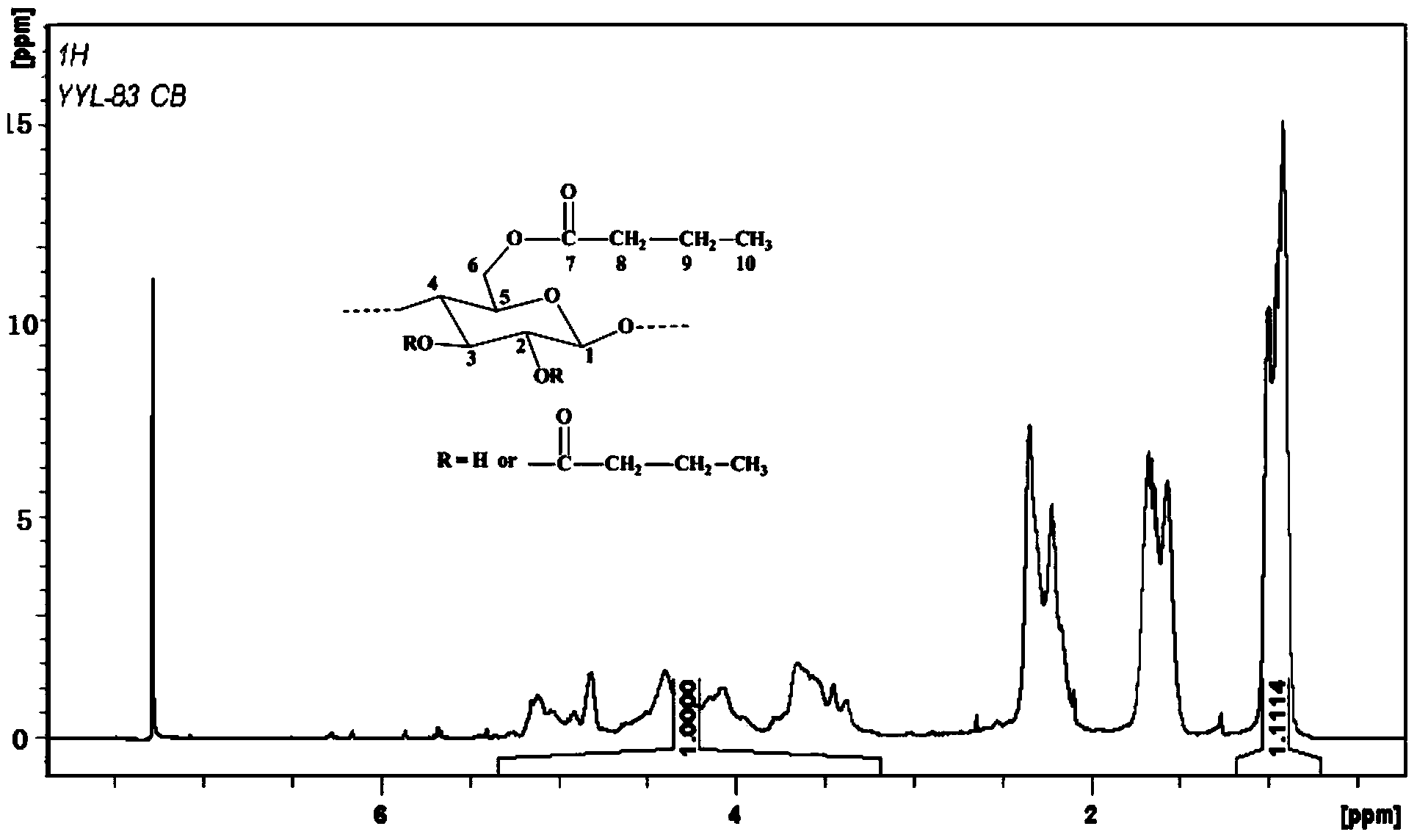

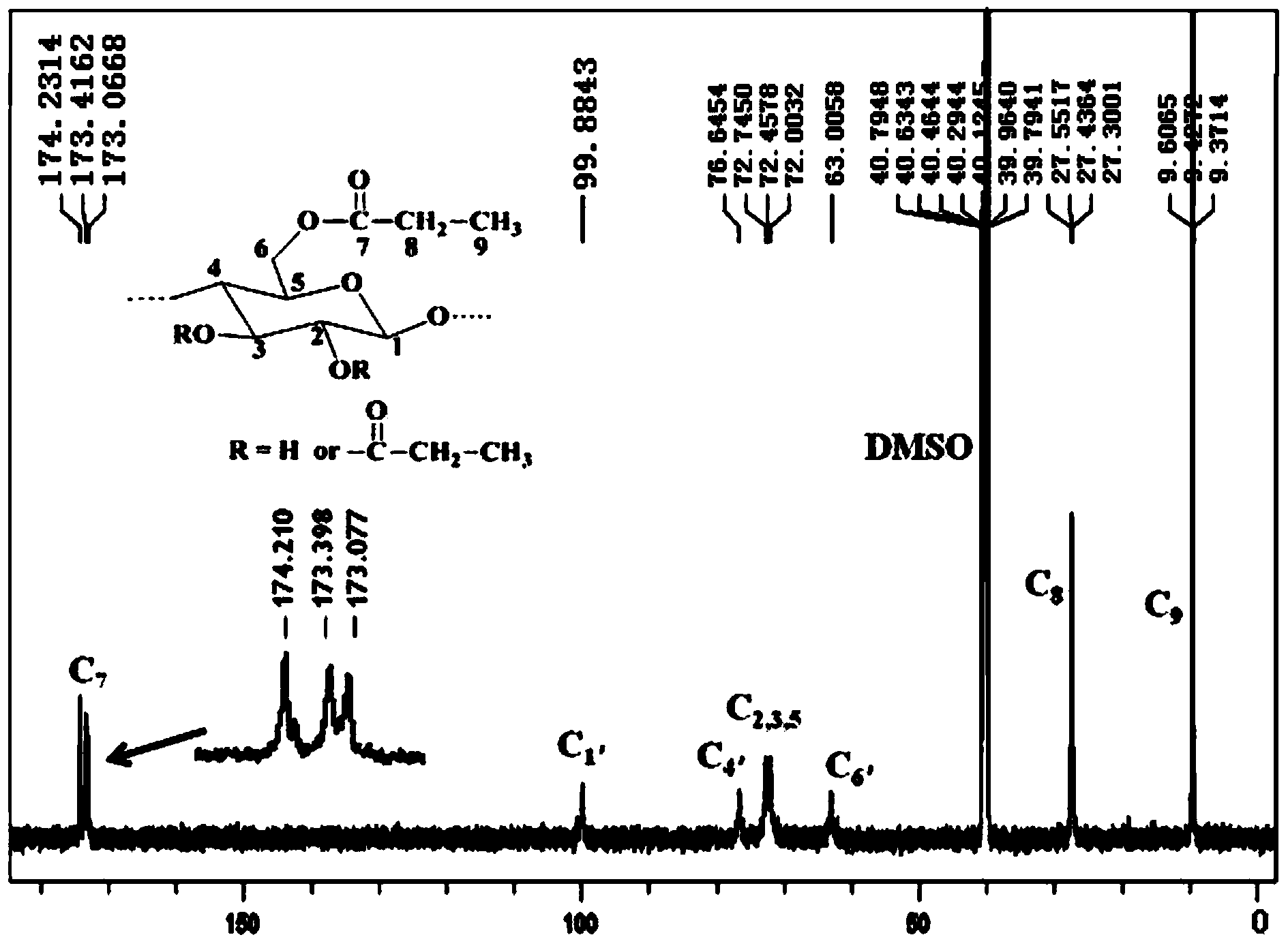

[0076] Weigh about 0.5g of α-cellulose, weigh about 10g of a mixed solution composed of 1,1,3,3-tetramethylguanidine (TMG), methanol and DMSO (DMSO accounts for 80% of the molar fraction of the mixed solution, methanol About 0.63g), put into the autoclave together, cover the autoclave, pass 2MPa CO 2 , the temperature is at 60°C, sealed with strong mechanical stirring for 3 hours, and a one-pot reaction is carried out to dissolve the cellulose. A clear and transparent cellulose solution was obtained, and the concentration of the cellulose solution was 5% (mass fraction). Raise the temperature to 80°C, and at the same time add acetic anhydride (about 3.64g) to the solution so that the molar ratio of acetic anhydride to the total hydroxyl groups in the cellulose solution is 1.2:1, and react for 5 hours. After the reaction was completed, the product was precipitated with 4 times the amount of methanol, and the solid product was repeatedly washed with water and freeze-dried for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com