Substrate processing apparatus

A substrate processing device and technology for substrates, which are applied in the fields of components, optics, and instruments for opto-mechanical processing, can solve the problems of prolonged drying time and reduced drying performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0020]

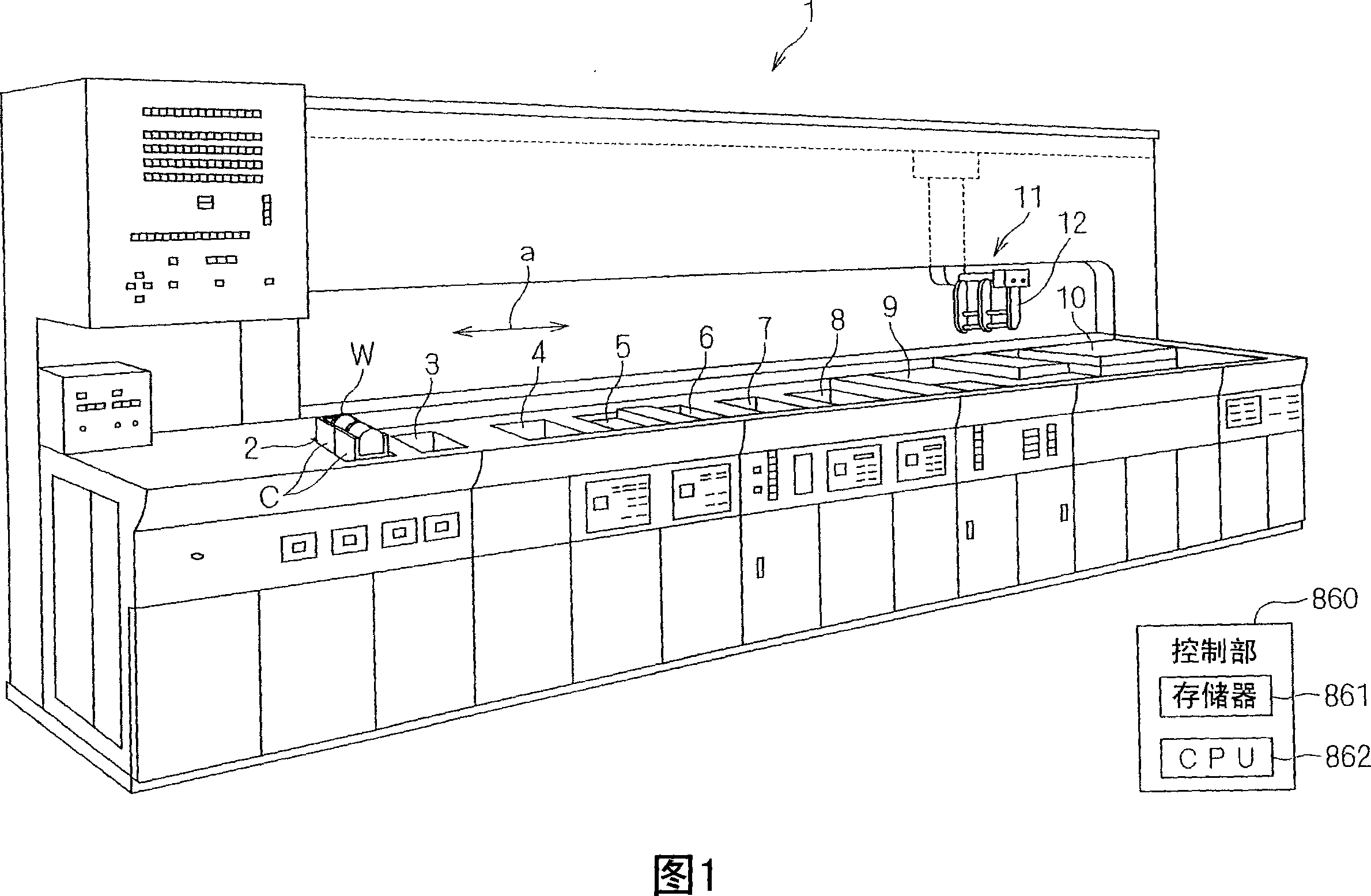

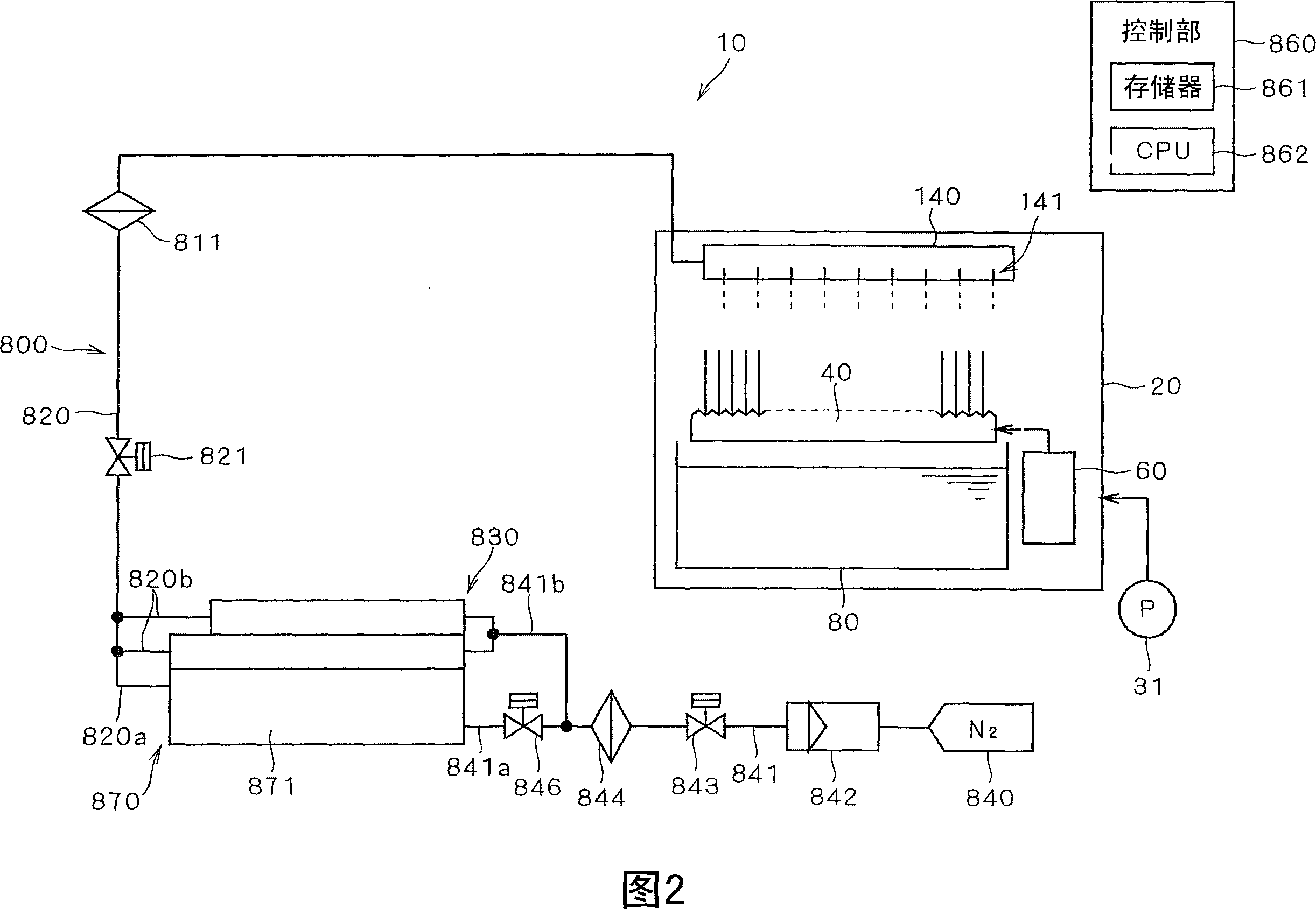

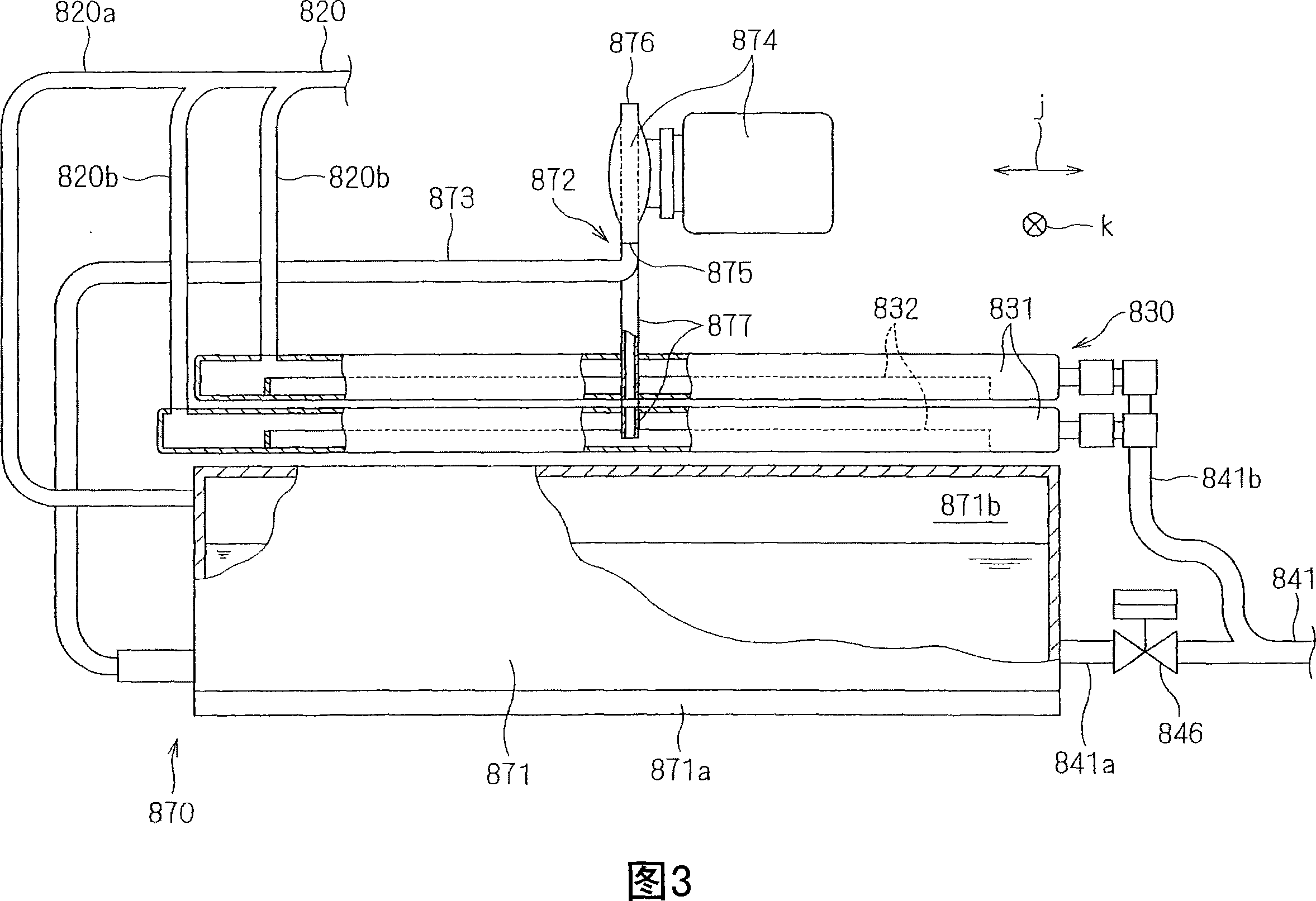

[0021] FIG. 1 is a perspective view showing an example of the overall structure of a wet bench 1 in an embodiment of the present invention. This wet bench 1 is a "batch type" substrate processing apparatus that processes a plurality of substrates W at a time. A cleaning process and a drying process are performed on a plurality of (for example, 26) substrates W accommodated in the cassette C using a chemical solution and pure water.

[0022] As shown in FIG. 1 , the wet bench 1 mainly includes a stacking unit 2 , a take-out unit 3 , processing units 4 to 9 , a decompression drying unit 10 , and a transfer robot 11 . Here, as shown in FIG. 1 , in this embodiment, the stacking unit 2 , the take-out unit 3 , the processing units 4 to 9 , and the reduced-pressure drying unit 10 are linearly arranged along the predetermined processing unit array directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com