Preparation method of intercalated nanocomposite foaming agent

A nanocomposite and foaming agent technology, applied in the field of intercalation compound preparation, can solve the problems of complex decomposition mechanism, no clear explanation, etc., and achieve the effect of improving agglomeration, improving agglomeration phenomenon and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

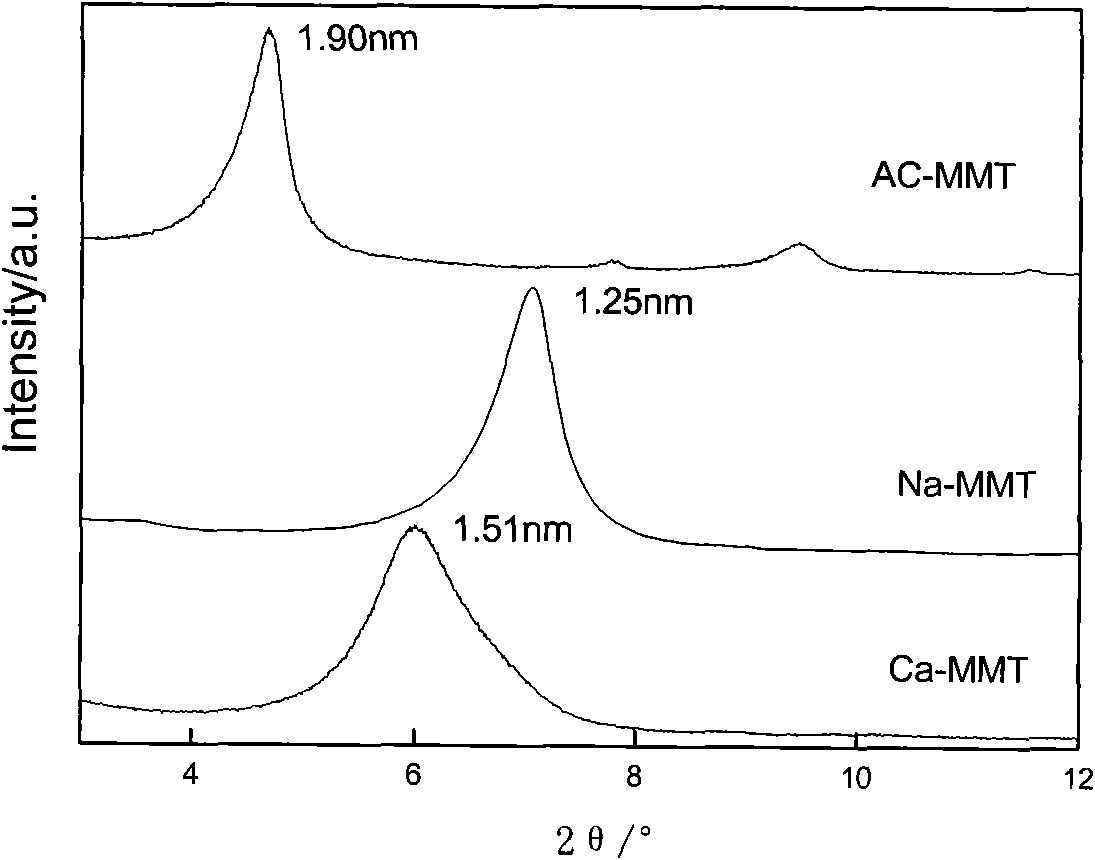

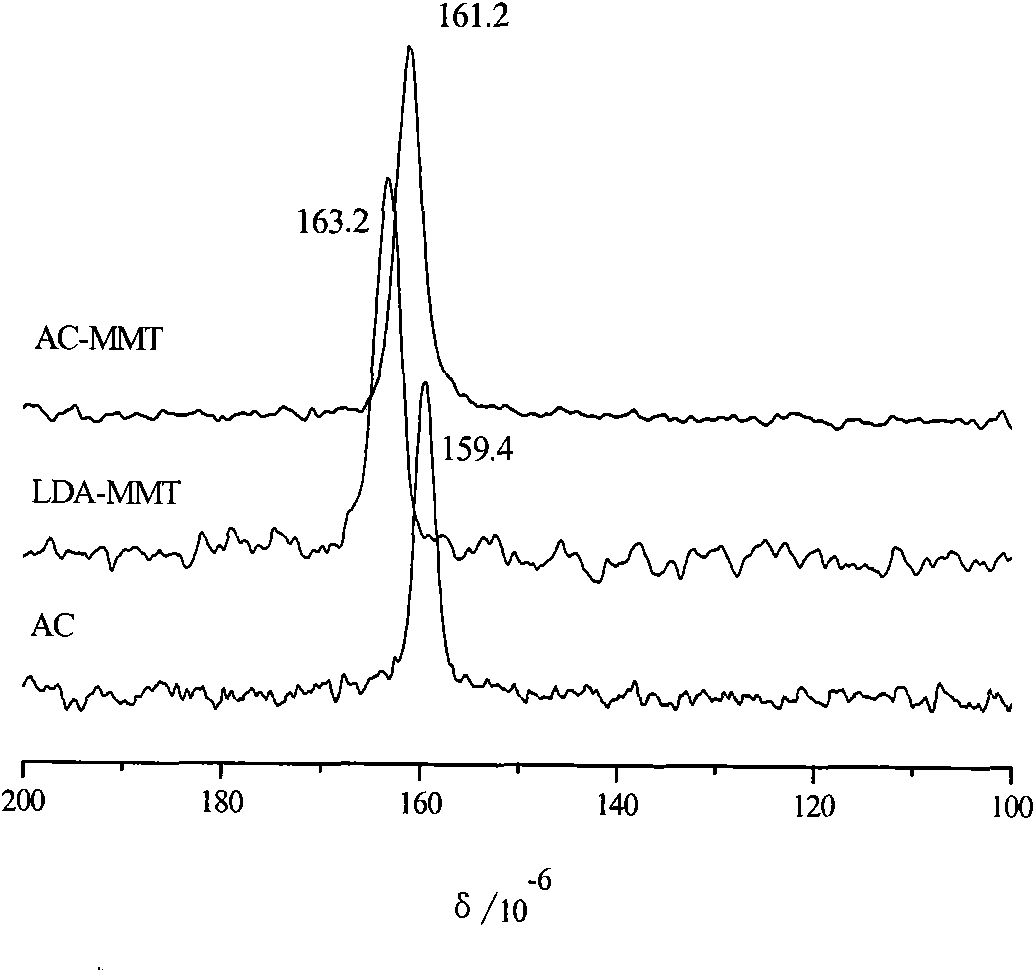

[0018] Disperse Na-montmorillonite in a certain amount of deionized water and stir for 1 hour. Azodicarbonamide was dissolved in a certain amount of dimethyl sulfoxide and added to the previous montmorillonite slurry. At a certain temperature, stir vigorously for 24 hours and then centrifuge, and then use appropriate amount of DMSO and CCl 4 Thoroughly wash the product multiple times to completely remove AC from the MMT surface. Vacuum-dried at 60°C for 24 hours to obtain the intercalation composite blowing agent AC-MMT.

[0019] Table 1 Preparation process parameters of azodicarbonamide / montmorillonite intercalation composite foaming agent

[0020]

Embodiment 2

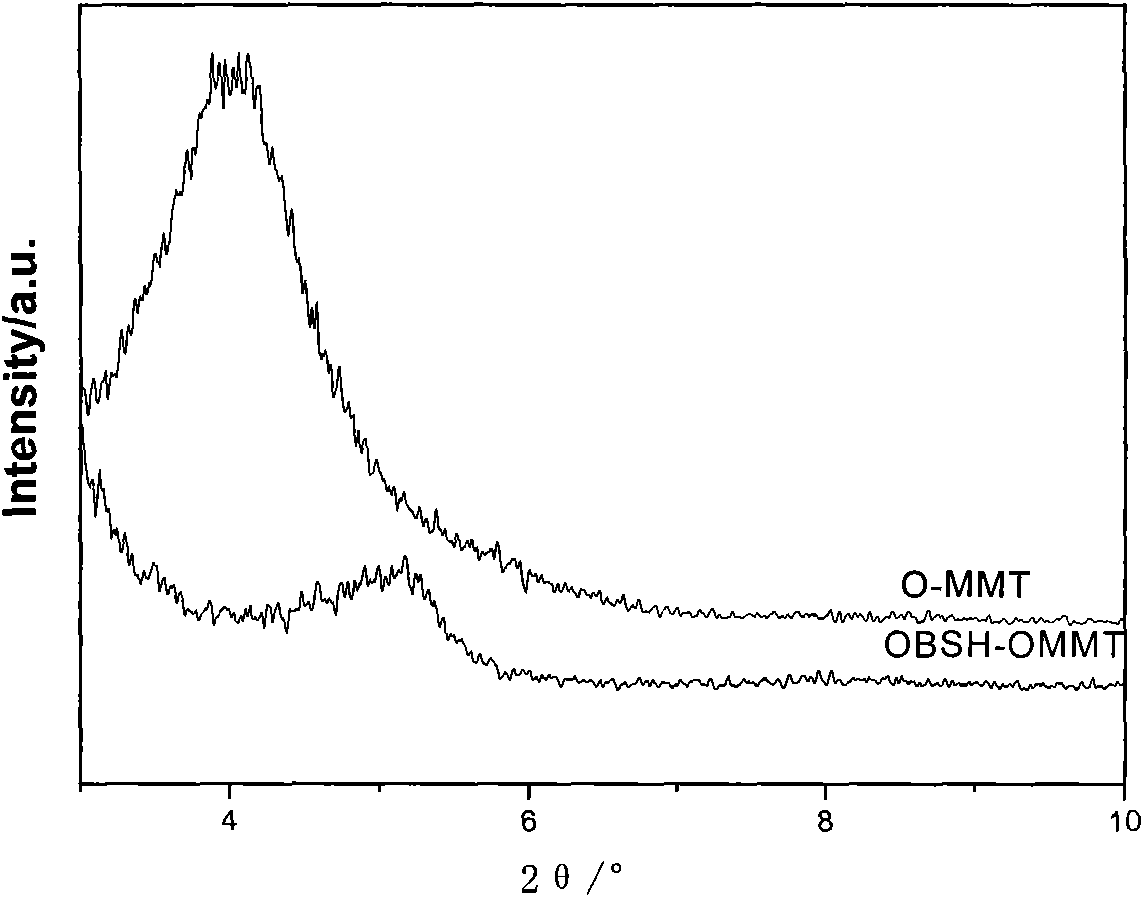

[0022] (1) Preparation of organic montmorillonite

[0023] Weigh 10g of sodium montmorillonite and suspend it in 300mL of deionized water, stir in a water bath and heat to 80°C; disperse 3g of cetyltrimethylammonium bromide (CTAB) in 20mL of deionized water and drop Add it to the above MMT suspension. Heat to 90°C in a water bath, stir at constant temperature for 4 hours, filter and wash with water for several times until there is no bromide ion, dry at 90°C, and grind to 300 mesh to obtain O-MMT.

[0024] (2) Preparation of 4,4 oxobisbenzenesulfonyl hydrazide-organized montmorillonite intercalation composite foaming agent

[0025] Organic montmorillonite O-MMT (1g) was dispersed in 30mL H 2 O; 1g of 4,4 oxobisbenzenesulfonyl hydrazide (OBSH) was dissolved in 20mL of DMSO, and the two were mixed. Stir for 24 hours, centrifuge, and dry at 60°C for 24 hours to obtain the intercalation composite foaming agent OBSH-OMMT.

[0026] Table 2 Parameters of preparation process of 4,4...

Embodiment 3

[0029] Foaming experiments were carried out with different formulations in Example 1. Raw materials: Stir intercalation composite foaming agent and silane coupling agent in ethylene glycol solution for 3 hours, dry, and then mix the obtained product with ethylene vinyl acetate copolymer resin (EVA) and stearic acid. 100 parts of EVA, 1.5 parts of composite blowing agent, and 1 part of stearic acid are used to form a mixture of the above raw materials. Stir in a high-speed mixer for 3 minutes, then knead in a screw extruder with a screw diameter of Φ32 and a screw extrusion speed of 50r / min. ℃, 180°C, 195°C, select the Φ4 monofilament die to extrude and foam to obtain a composite foam material. The intercalated composite foaming agent used therein is calculated according to the formula in Example 1.

[0030] The foaming effect of different proportions of foaming agents is different. Through the observation of the foamed materials, it is mainly to compare the uniformity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com