Nitrogen-doped carbon-coated vanadium nitride electrode material as well as preparation method and application thereof

An electrode material, nitrogen-doped carbon technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the cumbersome preparation method of porous carbon matrix, unfavorable lithium-sulfur battery charge and discharge performance, can not meet To meet the actual requirements and other issues, to achieve the effect of environmental protection and safety in the preparation process, excellent electrochemical performance, and inhibition of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

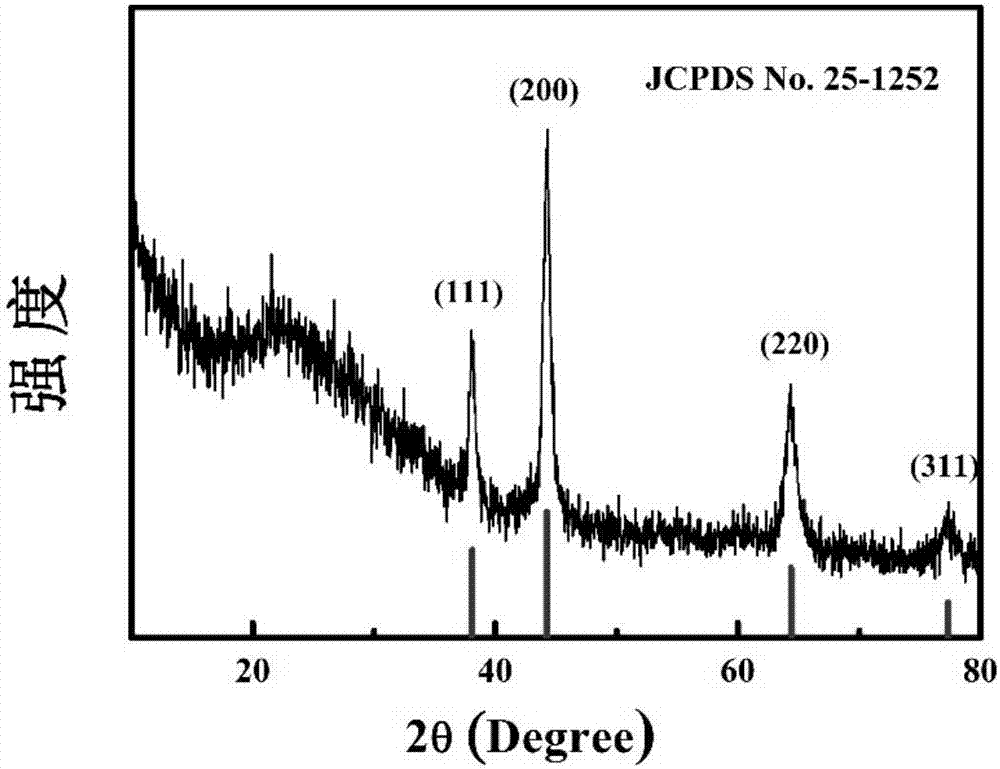

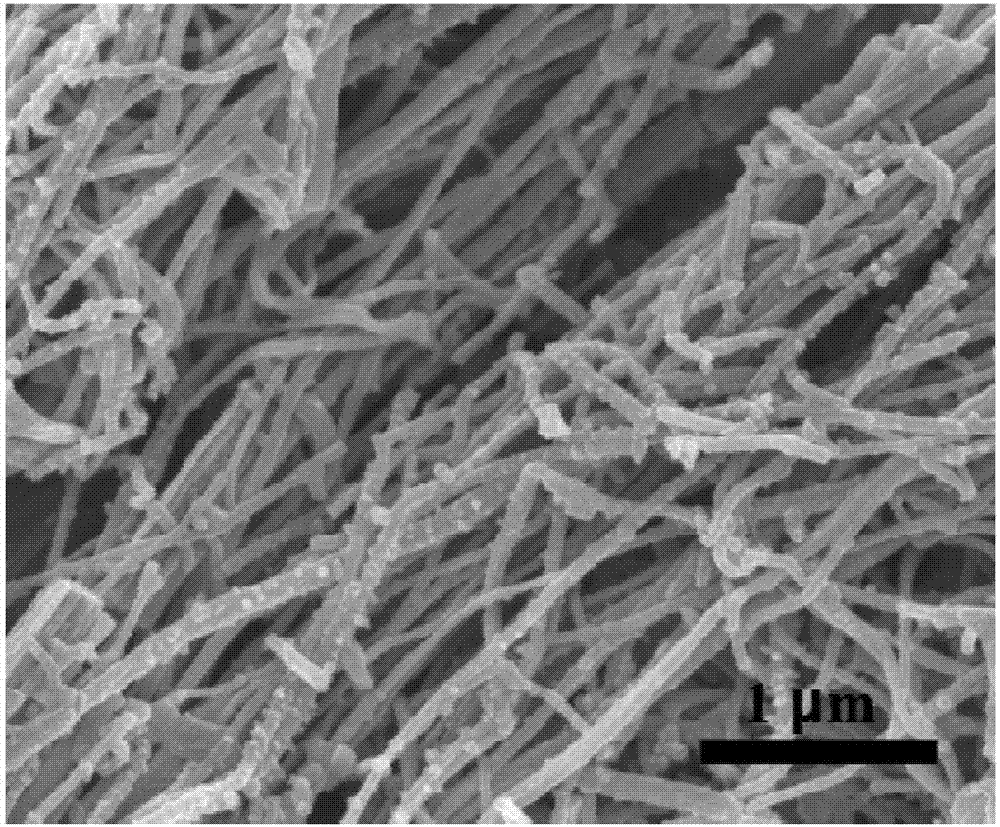

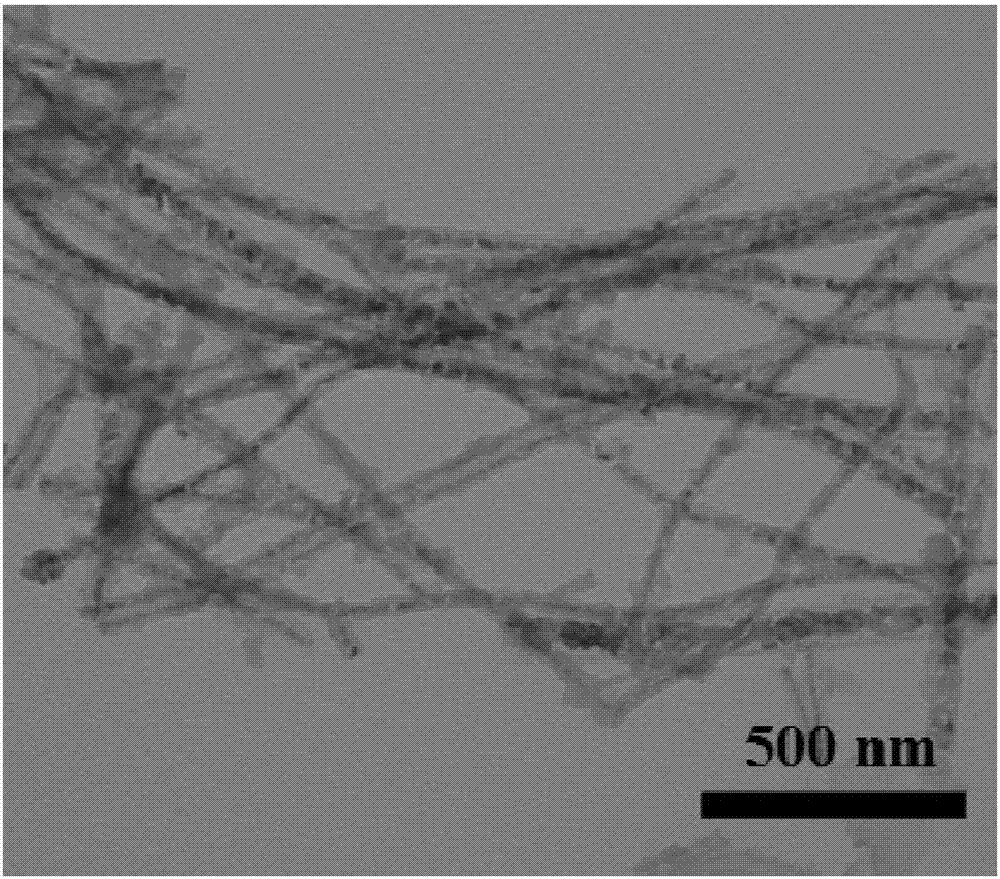

[0054] A nitrogen-doped carbon-coated vanadium nitride electrode material, the microscopic morphology of the electrode material is: the surface of the vanadium nitride nanowire is covered with nitrogen-doped carbon material; the average diameter of the vanadium nitride nanowire is 40nm, the average length is 1.5μm, and the average thickness of the nitrogen-doped carbon layer is 10nm;

[0055] The mass content of vanadium nitride in the electrode material is 75.9%, and the mass content of carbon is 24.1%.

[0056] The preparation method of the above-mentioned nitrogen-doped carbon-coated vanadium nitride electrode material includes the following steps:

[0057] (1) Dissolve 0.364g of vanadium pentoxide in 30ml of deionized water, add 5ml of aqueous hydrogen peroxide solution with a mass concentration of 30%, and stir at room temperature for 2 hours to obtain a mixed solution; hydrothermally react at 205°C for 4 days; , deionized water and absolute ethanol were alternately wash...

Embodiment 2

[0062] A preparation method of a nitrogen-doped carbon-coated vanadium nitride electrode material, the preparation steps are as described in Example 1, the difference is that the addition of pyrrole monomer in step (2) is 60 μL; the addition mass concentration is 1.3% The aqueous solution of ammonium persulfate 15mL, others are consistent with embodiment 1.

Embodiment 3

[0064] A method for preparing a nitrogen-doped carbon-coated vanadium nitride electrode material, comprising the following steps:

[0065] (1) Dissolve 0.364g of vanadium pentoxide in 30ml of deionized water, add 5ml of aqueous hydrogen peroxide solution with a mass concentration of 30%, and stir at room temperature for 2 hours to obtain a mixed solution; hydrothermally react at 200°C for 3 days; centrifuge , deionized water and absolute ethanol were washed alternately three times, and dried at 70°C for 4 hours to obtain a vanadium pentoxide nanowire precursor;

[0066] (2) Dissolve 0.4 g of sodium dodecylsulfonate in 50 mL of deionized water, add 0.1 g of the vanadium pentoxide nanowire precursor obtained in step (1) and 80 μL of pyrrole monomer, mix well and disperse evenly, and Stir at 0°C for 1 hour to obtain a reaction solution; under stirring conditions, add 10 mL of an aqueous solution of ammonium persulfate with a mass concentration of 2.6%, and react at 0°C for 5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com