Preparation method of flexible self-supporting iron-doped porous carbon nanofiber lithium metal negative electrode framework material

A lithium metal negative electrode and nanofiber technology is applied in the field of preparation of flexible self-supporting iron-doped porous carbon nanofiber lithium metal negative electrode skeleton materials, which can solve the problems of increasing battery internal resistance, battery short circuit, safety problems, etc. The method is simple, easy to scale production, and the effect of good practical prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Weigh 0.4g of iron acetylacetonate (Fe(C 5 h 7 o 2 ) 3 ), dissolved in 4.4g of N,N-dimethylformamide (DMF), then added 0.6g of polyacrylonitrile (PAN), 0.04g of polymethylmethacrylate (PMMA), and placed the resulting solution Stir magnetically in a water bath at 50° C. for 12 hours to form a uniform spinning solution.

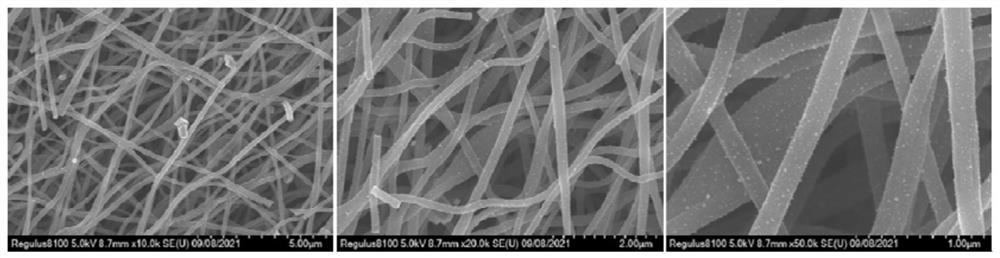

[0018] (2) Using the method of solution electrospinning, suck the prepared spinning solution into a medical syringe, connect the rotating receiver to a positive pressure of 10kV, and the needle to a negative pressure of 8kV, turn on the micro-syringe pump to propel the spinning solution at a speed of 0.5ml / h. The silk solution advances, the spinning solution is stretched under the action of the electric field force, the solvent is volatilized, and the precursor nanofiber film is obtained on the rotating receiver with a rotation speed of 900r / min, and the distance between the needle and the rotating receiver is 12cm. Wherein, the environmental par...

Embodiment 2

[0021] (1) Weigh 0.6g of iron acetylacetonate (Fe(C 5 h 7 o 2 ) 3 ), dissolved in 4.4g of N,N-dimethylformamide (DMF), then added 0.6g of polyacrylonitrile (PAN), 0.04g of polymethylmethacrylate (PMMA), and placed the resulting solution Stir magnetically in a water bath at 50° C. for 12 hours to form a uniform spinning solution.

[0022] (2) Using the method of solution electrospinning, suck the prepared spinning solution into a medical syringe, connect the rotating receiver to a positive pressure of 10kV, and the needle to a negative pressure of 8kV, turn on the micro-syringe pump to propel the spinning solution at a speed of 0.5ml / h. The silk solution advances, the spinning solution is stretched under the action of the electric field force, the solvent is volatilized, and the precursor nanofiber film is obtained on the rotating receiver with a rotation speed of 900r / min, and the distance between the needle and the rotating receiver is 12cm. Wherein, the environmental par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com