Cross-linked anion membrane, preparation method thereof and application

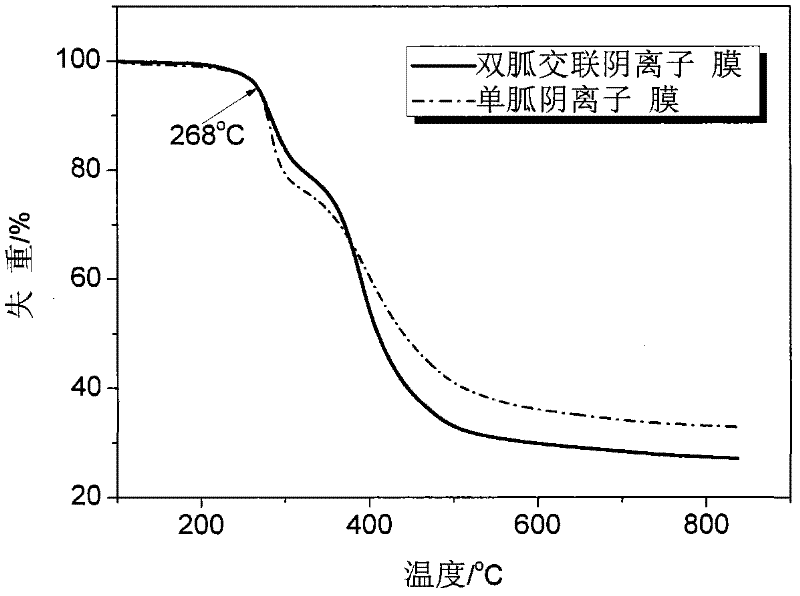

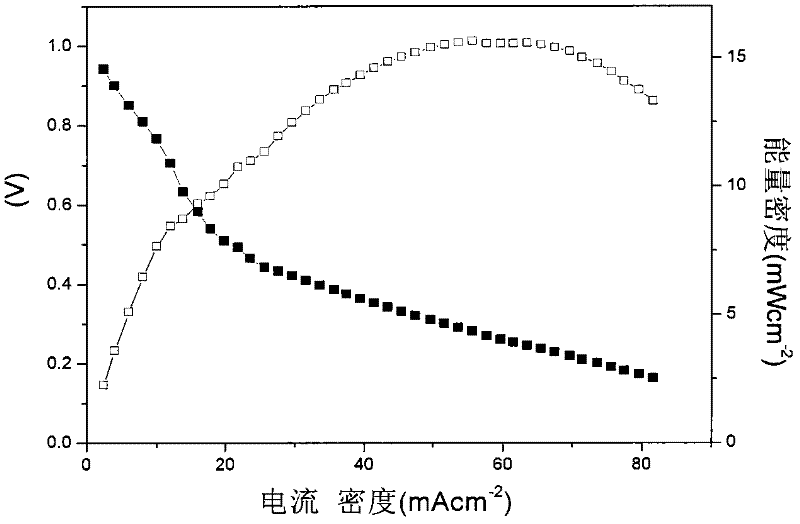

A technology for cross-linking anion membranes and anion membranes, which can be used in fuel cells, electrical components, electrochemical generators, etc., and can solve problems such as unfavorable oxidation stability and reduced battery Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

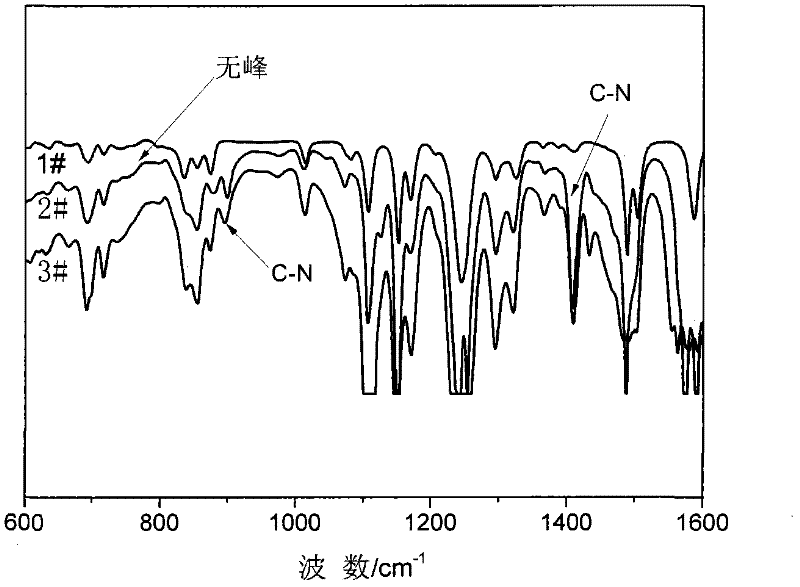

[0085] Under nitrogen atmosphere, at 0°C, add 1 mass part of tetramethylurea dissolved in 8 mass parts of ether, after mixing evenly, drop 4 mass parts of oxalyl chloride into the system at a speed of 2 drops / s After the dropwise addition, stir for 30 minutes, slowly raise the temperature to 60° C., and reflux for 3 hours. The solvent was removed by evaporation. A pale yellow solid was obtained. That is tetramethyl Vilsmeyer salt.

[0086]Dissolve 1 mole fraction of the prepared tetramethyl Vilsmeyer salt in 10 mole fractions of acetonitrile, slowly add 1 mole fraction of dry methylamine, after the addition, slowly raise the temperature to 90°C and reflux for over 4 hours. Stop responding. Under vigorous stirring, add 5molL -1 NaOH aqueous solution until the solution is clear. Separate the organic phase and remove the solvent to prepare pentamethylguanidine.

[0087] 1 mole fraction of the prepared Vilsmeyer salt was dissolved in 10 mole fractions of acetonitrile, and a ...

Embodiment 2

[0096] Under nitrogen atmosphere, at 0°C, add 1 mass part of tetramethylurea dissolved in 8 mass parts of ether, after mixing evenly, drop 4 mass parts of oxalyl chloride into the system at a speed of 2 drops / s After the dropwise addition, stir for 30 minutes, slowly raise the temperature to 60° C., and reflux for 3 hours. The solvent was removed by evaporation. A pale yellow solid was obtained. That is tetramethyl Vilsmeyer salt.

[0097] Dissolve 1 mole fraction of the prepared tetramethyl Vilsmeyer salt in 10 mole fractions of acetonitrile, slowly add 1 mole fraction of dry methylamine, after the addition, slowly raise the temperature to 90°C and reflux for over 4 hours. Stop responding. Under vigorous stirring, add 5molL -1 NaOH aqueous solution until the solution is clear. Separate the organic phase and remove the solvent to prepare pentamethylguanidine.

[0098] 1 mole fraction of the prepared Vilsmeyer salt was dissolved in 10 mole fractions of acetonitrile, and a...

Embodiment 3

[0104] Under an argon atmosphere, at 5°C, add 1 mass part of N,N-diethylpropenyl urea dissolved in 10 mass parts of dichloromethane, mix well, and add dropwise at a speed of 3 drops / s 6 parts by mass of oxalyl chloride was added to the system, after the dropwise addition, stirred for 20 minutes, slowly heated to 50°C, and refluxed for 4 hours. The solvent was removed by evaporation. A pale yellow solid was obtained. That is N, N-diethylpropenyl Vilsmeyer salt.

[0105] Take the prepared 1 mole fraction of N,N-diethylpropenyl Vilsmeyer salt and dissolve it in acetonitrile, and slowly add a dry mixture of 0.5 mole fractions of 1,6-hexanediamine and 2 mole fractions of triethylamine . After the dropwise addition, the temperature was slowly raised to 100° C. for reflux reaction for 24 hours. Under vigorous stirring, add 10molL -1 KOH aqueous solution until the system is clear. Separate the organic phase, remove the solvent and triethylamine, and dry in vacuum to prepare N,N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com