Cu-Ag/carbon nanometer fiber composite material and preparation method and application thereof

A carbon nanofiber and composite material technology, applied in the field of carbon fiber, can solve the problems of low specific capacitance and poor cycle performance, and achieve the effects of large specific capacitance, improved conductivity, and optimized process reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

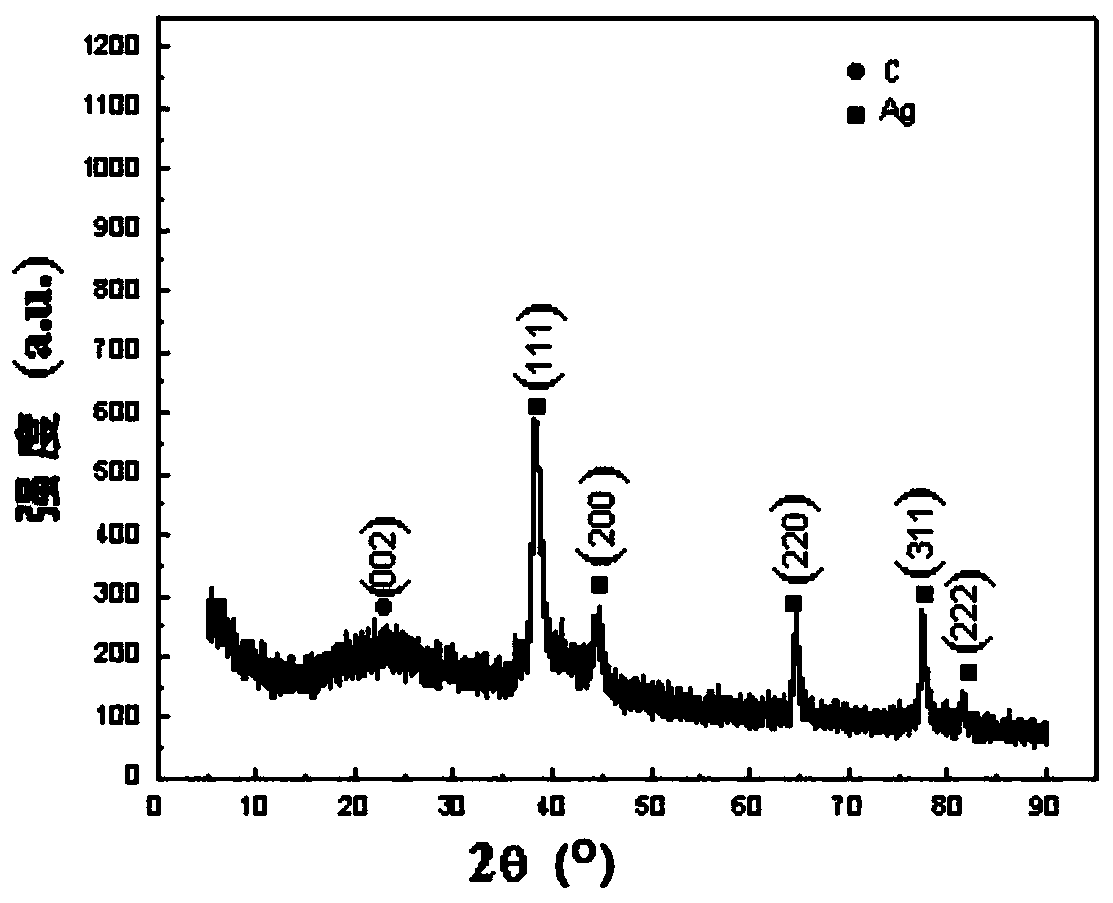

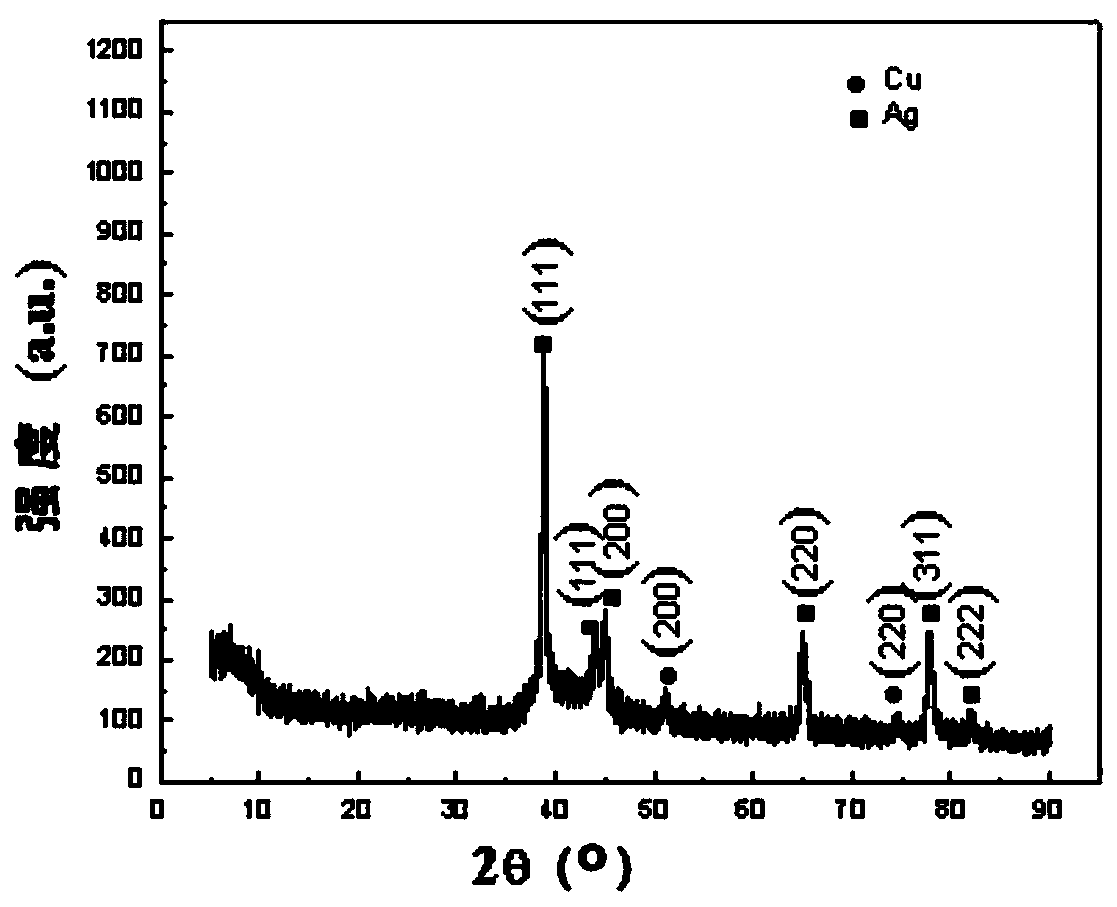

Image

Examples

Embodiment 1

[0032] The preparation method of Cu-Ag / carbon nanofiber composite material comprises the following steps:

[0033] (1) Preparation of spinning solution: Weigh 1.102g of polyacrylonitrile and dissolve it in 12mL of N,N-dimethylformamide solvent, stir well to obtain solution A; weigh 1.332g of copper acetate and pour it into solution A , stirred at room temperature for 3 hours to obtain a mixed solution B; weighed 1.331 g of silver acetate and poured it into the mixed solution B, and stirred at room temperature for 2 hours to obtain a mixed solution C;

[0034] (2) Preparation of the precursor: place the mixed solution C in the syringe, and perform electrospinning at a voltage of 15kV, a flow rate of 1mL / h and a height of 15cm. After the electrospinning is completed, dry at room temperature overnight. Precursor Cu-Ag / PAN nanofibers were prepared;

[0035] (3) Preparation of Cu-Ag / carbon nanofiber composite material: the precursor obtained in step (2) was placed in a porcelain b...

Embodiment 2

[0043] The preparation method of Cu-Ag / carbon nanofiber composite material comprises the following steps:

[0044] (1) Preparation of spinning solution: Weigh 0.302g of polyacrylonitrile and dissolve it in 12mL of N,N-dimethylformamide solvent, stir well to obtain solution A; weigh 1.331g of copper acetate and pour it into solution A , stirred at room temperature for 3 hours to obtain a mixed solution B; weighed 1.332 g of silver acetate and poured it into the mixed solution B, stirred at room temperature for 2 hours to obtain a mixed solution C;

[0045] (2) Preparation of the precursor: place the mixed solution C in the syringe, and perform electrospinning at a voltage of 15kV, a flow rate of 1mL / h and a height of 20cm. After the electrospinning is completed, dry at room temperature overnight. Prepare Cu-Ag / PAN nanofibers;

[0046] (3) Preparation of Cu-Ag / carbon nanofiber composite material: the nanofibers obtained in step (2) are placed in a porcelain boat, 2 Under the c...

Embodiment 3

[0050] The preparation method of Cu-Ag / carbon nanofiber composite material comprises the following steps:

[0051] (1) Preparation of spinning solution: Weigh 0.801g of polyacrylonitrile and dissolve it in 12mL of N,N-dimethylformamide solvent, stir well to obtain solution A; weigh 1.332g of copper acetate and pour it into solution A , stirred at room temperature for 3 hours to obtain a mixed solution B; weighed 1.335 g of silver acetate and poured it into the mixed solution B, and stirred at room temperature for 3.5 hours to obtain a mixed solution C;

[0052] (2) Preparation of the precursor: place the mixed solution C in the syringe, and perform electrospinning at a voltage of 20kV, a flow rate of 0.8mL / h and a height of 10cm, and dry overnight at room temperature after electrospinning , making Cu / PAN nanofibers;

[0053] (3) Preparation of Cu-Ag / carbon nanofiber composite material: place the nanofiber obtained in step (2) in a porcelain boat, and heat it from room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com