Metal plating-based electrical energy storage cell

A storage unit and plating technology, applied in the field of electrochemical energy storage units, can solve the problems of carbon anode metal lithium plating, safety risks, and increased cost of large multi-unit batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

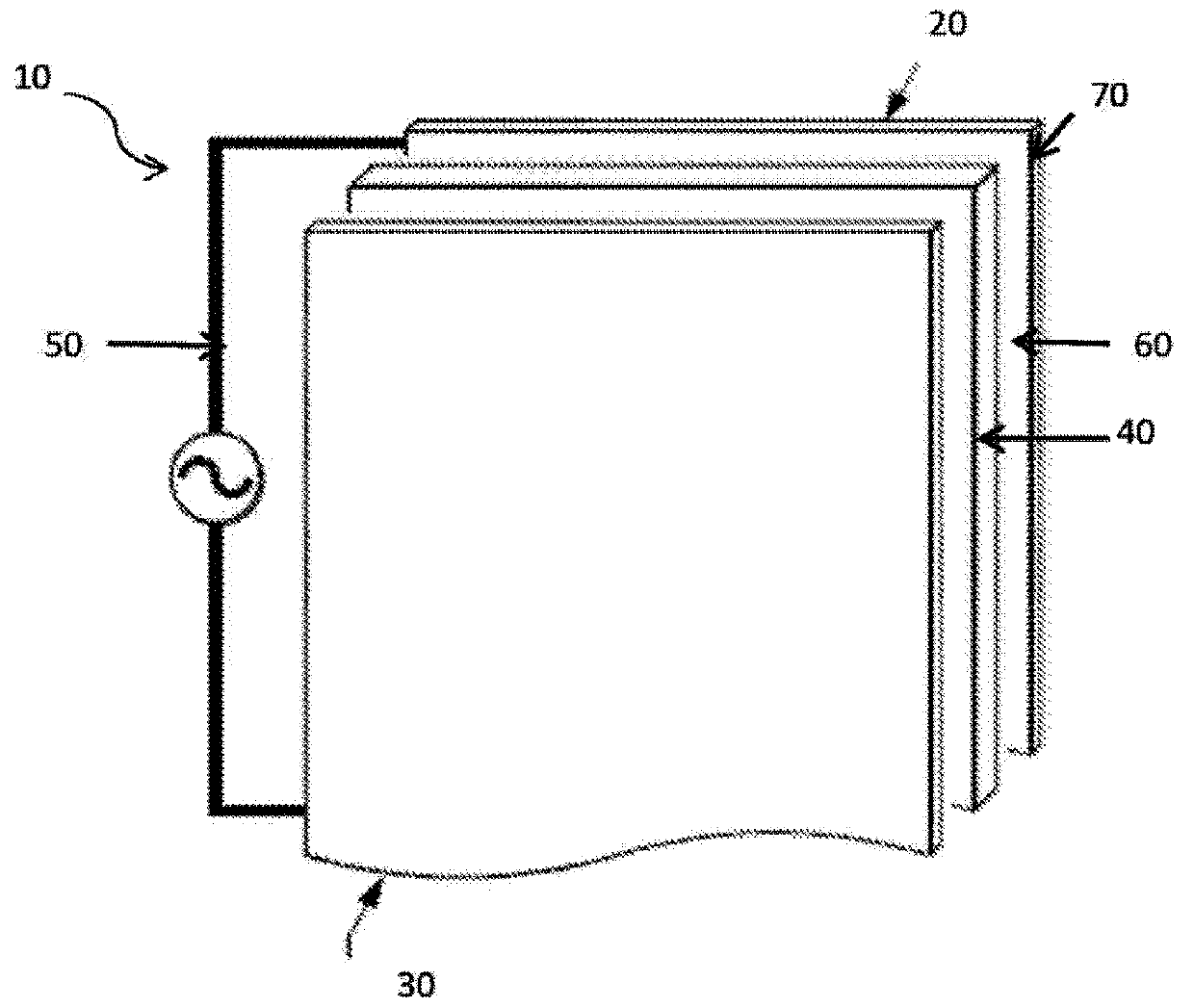

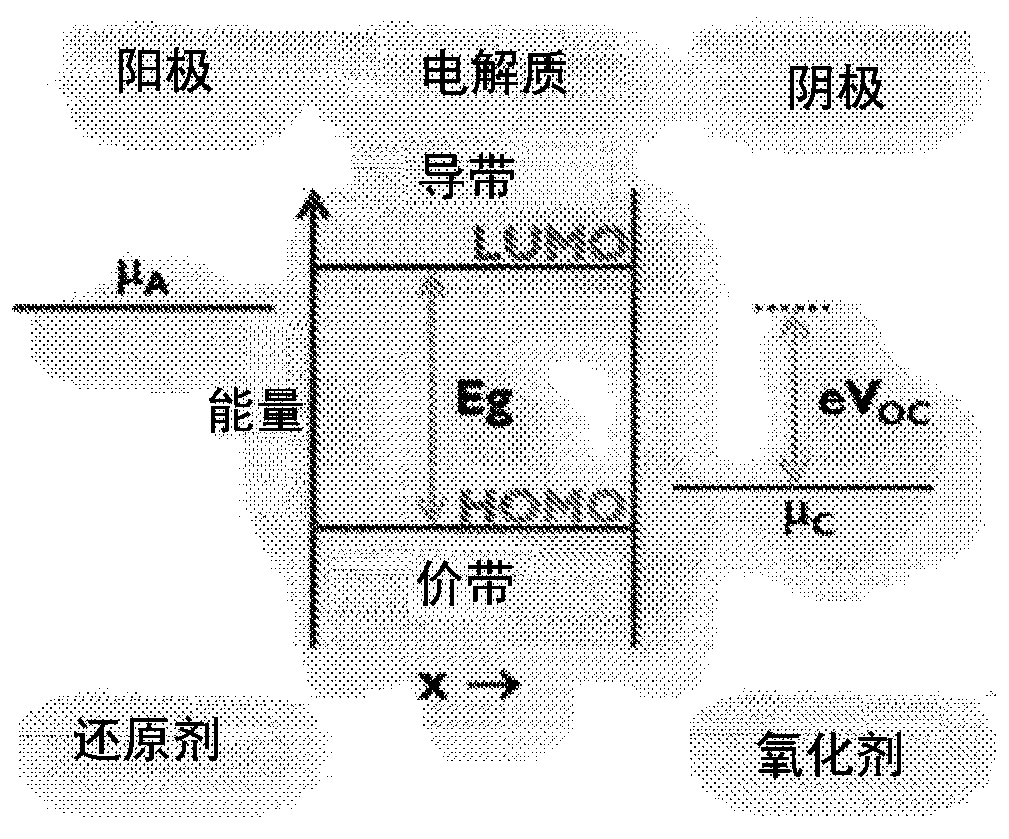

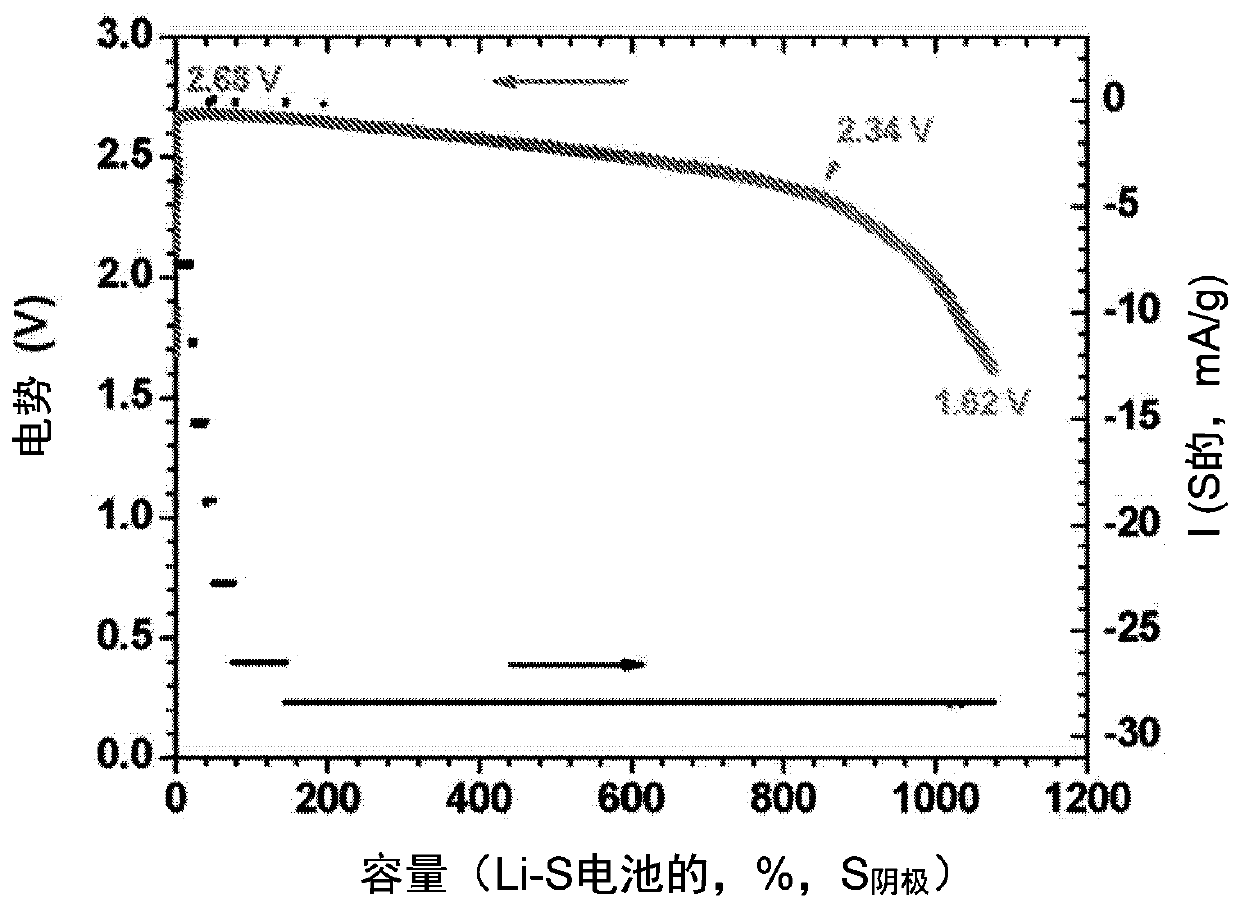

[0022] The present disclosure relates to metal plating based electrical energy storage cells. The unit may comprise batteries, especially rechargeable batteries, and various combinations of batteries and supercapacitors. More specifically, the present disclosure describes all-solid-state rechargeable cells in which cations of metals plated on an anode current collector are supplied by an electrolyte during charging. Batteries according to the present disclosure can have a high energy storage capacity with a high charge rate and a long operating life after multiple cycles. Ultracapacitors according to the present disclosure may have optimized or increased volumetric stored energy densities.

[0023] Batteries and supercapacitors according to the present disclosure may comprise a solid electrolyte comprising electric dipoles oriented parallel to each other and, if the electrodes or current collectors have a large energy difference in electrochemical potential, faradaic electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com