Preparation method of flexible composite material, water-system nickel-iron battery electrode containing flexible composite material, and battery

A composite material and flexible technology, applied in the direction of battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of unsatisfactory electrochemical performance and uneven dispersion, achieve high specific capacity, increase energy density, and increase magnification performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Other characteristics, characteristics and advantages of the present invention will be more apparent after the following detailed description of the embodiments of the present invention by way of examples in conjunction with the accompanying drawings.

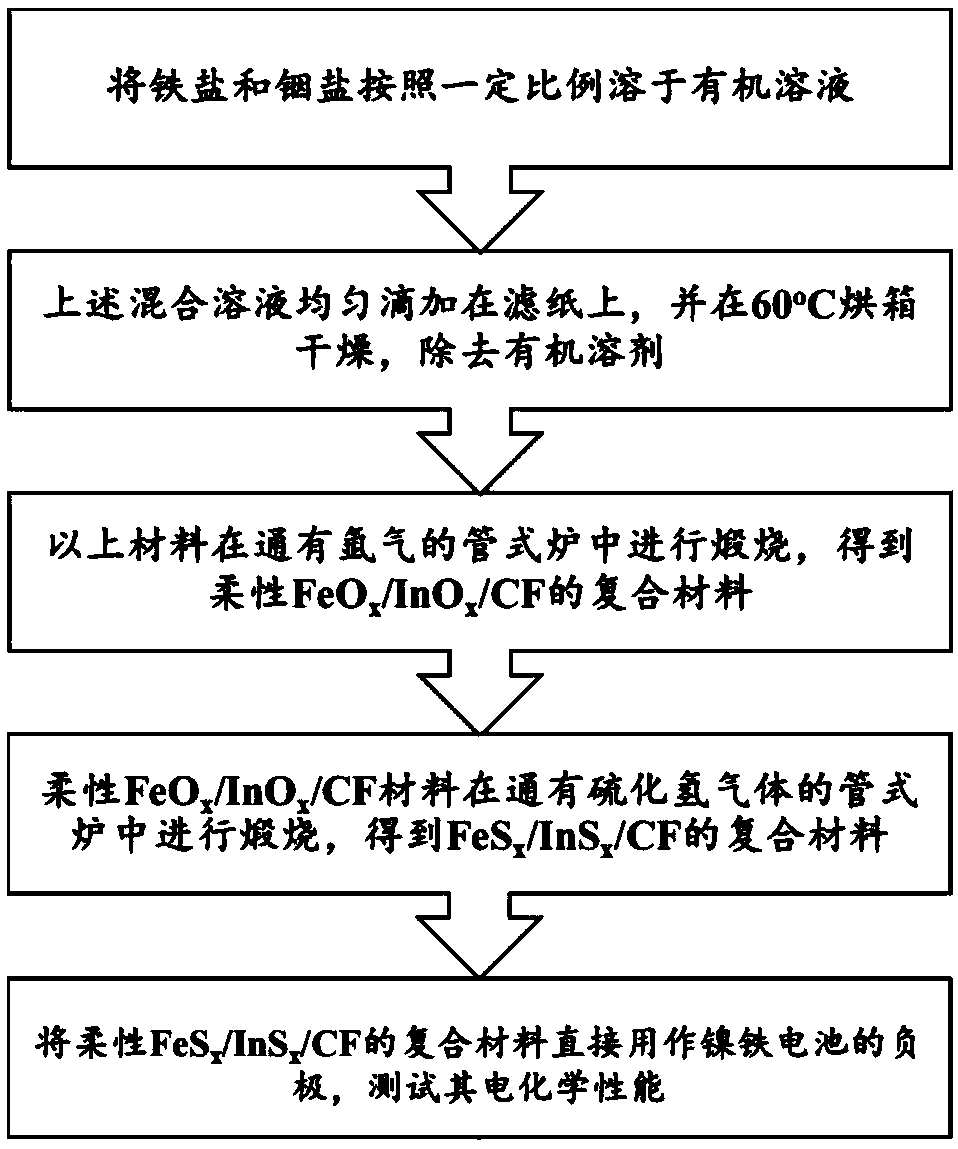

[0024] figure 1 Preparation of flexible FeS provided by the embodiment of the present invention x / InS x Schematic flow chart of the method for / CF composites. Such as figure 1 As shown, the embodiment of the present invention provides the preparation of flexible FeS x / InS x / CF composite material method, wherein, 0<x≤3, the preparation method comprises the following steps:

[0025] Step 1, dissolving iron acetylacetonate and indium acetylacetonate in an organic solvent;

[0026] In one embodiment, iron acetylacetonate and indium acetylacetonate are dissolved in an organic solvent at a molar ratio of 90:10, 85:15 or 80:20. The organic solvent adopts ethanol.

[0027] Step 2, drop the above mixed solution onto t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com