Method for preparing lithium-sulfur battery with TiO2 being as additive

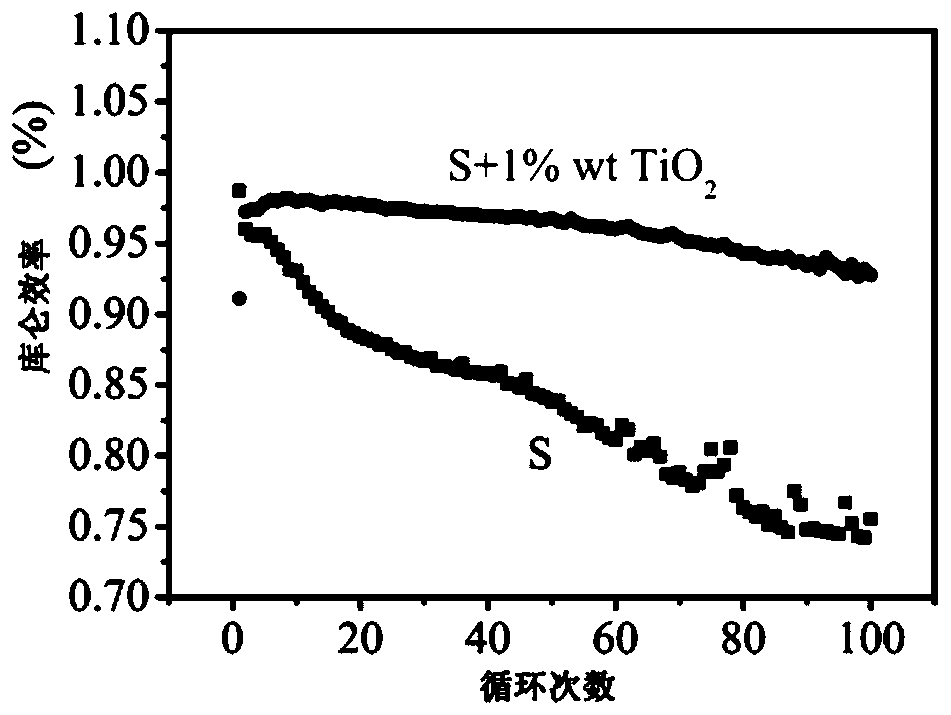

A lithium-sulfur battery and additive technology, which is applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low coulombic efficiency, shorten battery cycle life, and restrict the practical progress of lithium-sulfur batteries, and achieve the improvement of coulombic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The active material (sulfur + TiO 2 ), acetylene black and polytetrafluoroethylene (PTFE), the mass ratio of the three is 60:30:10, dispersed in the ethanol solution, the quality of ethanol is 100 times the mass of the active substance, ultrasonic 30 minutes under 40MHZ, and then The dispersion liquid was placed in a ball mill tank, and ball milled at a speed of 400 rpm for 12 hours to obtain a slurry. Apply the slurry on the aluminum foil and dry it in a blast drying oven; then place it in a vacuum drying oven and dry it under vacuum (less than -0.8Mpa) at 50 degrees Celsius for 12 hours. That is, the positive electrode sheet of the lithium-sulfur battery is obtained. The selected TiO 2 The material is mesoporous spherical TiO 2 (diameter 250nm, pore size 4nm). TiO 2 The proportion of the active substance is 0.2wt%.

Embodiment 2

[0022] The active material (sulfur + TiO 2 ), acetylene black and polytetrafluoroethylene (PTFE), the mass ratio of the three is 60:30:10, dispersed in the ethanol solution, the quality of ethanol is 100 times the mass of the active substance, ultrasonic 30 minutes under 40MHZ, and then The dispersion liquid was placed in a ball mill tank, and ball milled at a speed of 400 rpm for 12 hours to obtain a slurry. Apply the slurry on the aluminum foil and dry it in a blast drying oven; then place it in a vacuum drying oven and dry it under vacuum (less than -0.8Mpa) at 50 degrees Celsius for 12 hours. That is, the positive electrode sheet of the lithium-sulfur battery was obtained. The selected TiO 2 The material is mesoporous spherical TiO 2 (diameter 250nm, pore size 4nm). TiO 2 The proportion of the active substance is 0.5wt%.

Embodiment 3

[0024] The active material (sulfur + TiO 2 ), acetylene black and polytetrafluoroethylene (PTFE), the mass ratio of the three is 60:30:10, dispersed in the ethanol solution, the quality of ethanol is 100 times the mass of the active substance, ultrasonic 30 minutes under 40MHZ, and then The dispersion liquid was placed in a ball mill tank, and ball milled at a speed of 400 rpm for 12 hours to obtain a slurry. Apply the slurry on the aluminum foil and dry it in a blast drying oven; then place it in a vacuum drying oven and dry it under vacuum (less than -0.8Mpa) at 50 degrees Celsius for 12 hours. That is, the positive electrode sheet of the lithium-sulfur battery was obtained. The selected TiO 2 The material is mesoporous spherical TiO 2 (340nm diameter, 20nm pore size). TiO 2 The proportion of the active substance is 1wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com