Capacitive deionization unit, device and method

A capacitive deionization and anion technology, applied in the field of desalination of water resources, can solve the problems of increasing desalination capacity and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

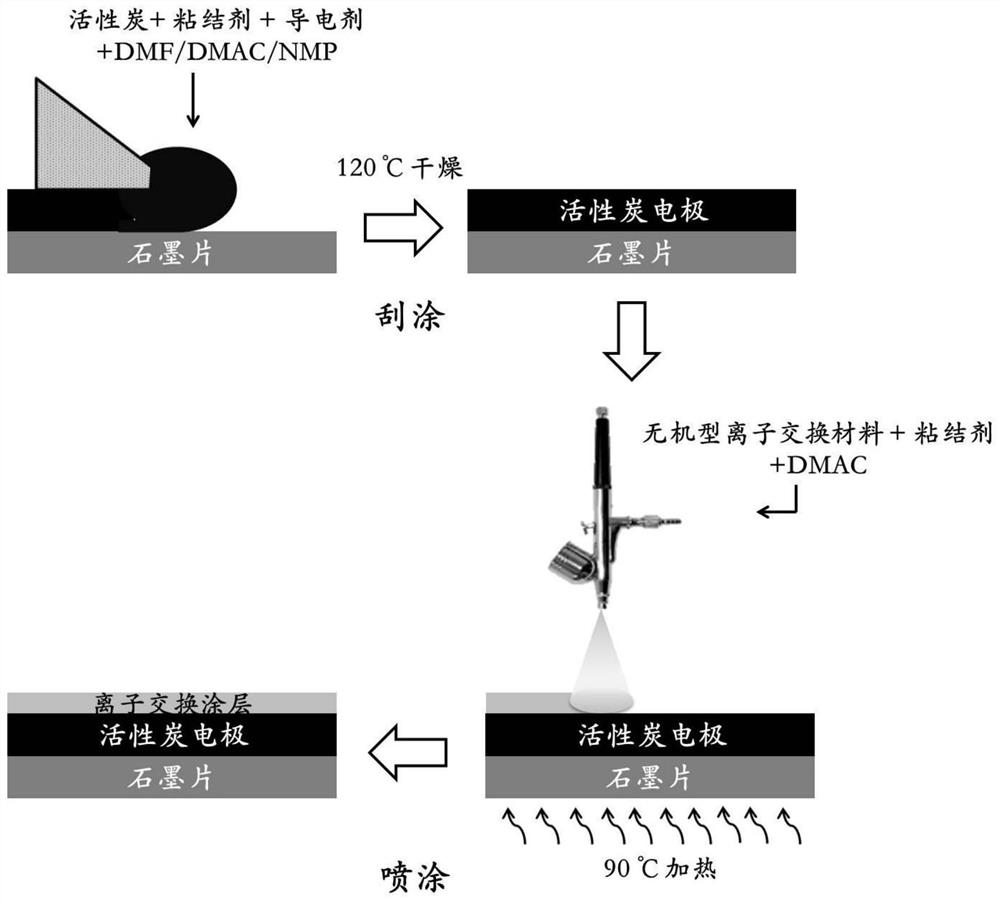

[0029] In other embodiments, the preparation method of the anion exchange layer includes: mixing the inorganic anion selective material with polyvinylidene fluoride, and spraying it on the surface of the porous carbon layer of the anode current collector; the cation exchange layer The preparation method includes: mixing the inorganic cation selective material with polyvinylidene fluoride (PVDF), dispersing it in N,N-dimethylacetamide (DMAC), and spraying it on the porous carbon layer of the cathode current collector surface. In these examples, after the powders of cation exchange materials and anion exchange materials are ball milled, the N,N-dimethylacetamide dispersion containing cation exchange materials and binder polyvinylidene fluoride is uniformly covered by ultrasonic spraying On the surface of the porous carbon layer of the cathode, the N,N-dimethylacetamide dispersion liquid of the anion exchange material and polyvinylidene fluoride is evenly covered on the surface o...

Embodiment 1

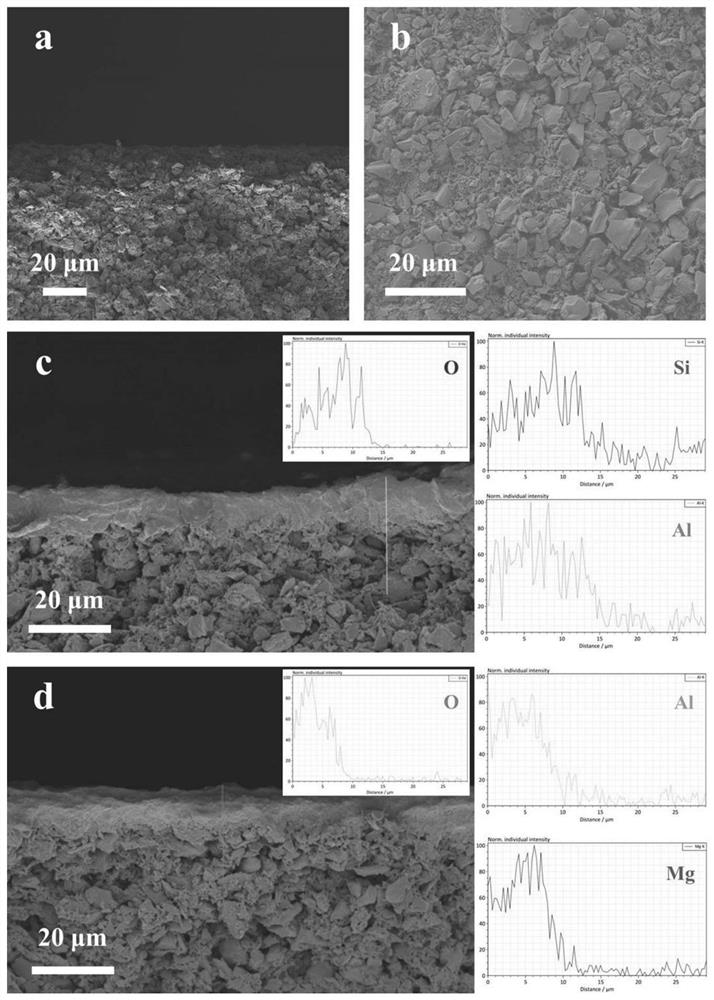

[0039] Example 1: Commercial activated carbon, conductive agent acetylene black and binder PVDF were used to prepare activated carbon electrodes, and the thickness of the electrodes was controlled to be between 100 and 200 microns. Using montmorillonite and PVDF mixed in a ratio of 5:1 to prepare a cation exchange coating on the surface of the cathode by ultrasonic spraying, using a mixture of hydrotalcite and PVDF in a ratio of 10:1 to prepare an anion exchange coating on the surface of the anode by ultrasonic spraying, ion exchanger The load was 1 mg / cm2. For surface characterization of ion exchange coatings see figure 2 , compared to the single-layer uniform structure of the pristine activated carbon electrode (4a), the composite electrodes (4c and 4d) both showed a layered structure with a dense upper layer and a porous lower layer. Through element detection, it can be found that the upper layer of the montmorillonite-coated electrode contains abundant Si, Al, and O elem...

Embodiment 2

[0041] Example 2: Commercial activated carbon, conductive agent acetylene black and binder PVDF were used to prepare activated carbon electrodes, and the thickness of the electrodes was controlled to be between 100 and 200 microns. Mix montmorillonite and PVDF in a ratio of 3:1 to prepare a cation-exchange coating on the surface of the cathode by ultrasonic spraying, use a mixture of hydrotalcite and PVDF in a ratio of 5:1 to prepare an anion-exchange coating on the surface of the anode by ultrasonic spraying, ion exchanger The load was 2 mg / cm2. Select simulated brine (initial concentration is 500 mg / L sodium chloride solution). Under normal temperature and pressure, a given constant voltage of 1.2 volts is charged for 15 minutes for adsorption and desalination, and a given constant voltage of 0 volts is discharged for 15 minutes for desorption and desalination, which is a complete cycle. Using unidirectional continuous flow, the system continues to work for more than 50 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com