Tin-nickel-carbon alloy composite material for lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and composite materials, which is applied in the field of tin-nickel-carbon alloy composite materials for lithium-ion batteries and its preparation, can solve the problems of powdered electrode performance of electrode materials, poor battery cycle performance, and deterioration, so as to improve the overall capacity , Improve the effect of cycle stability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

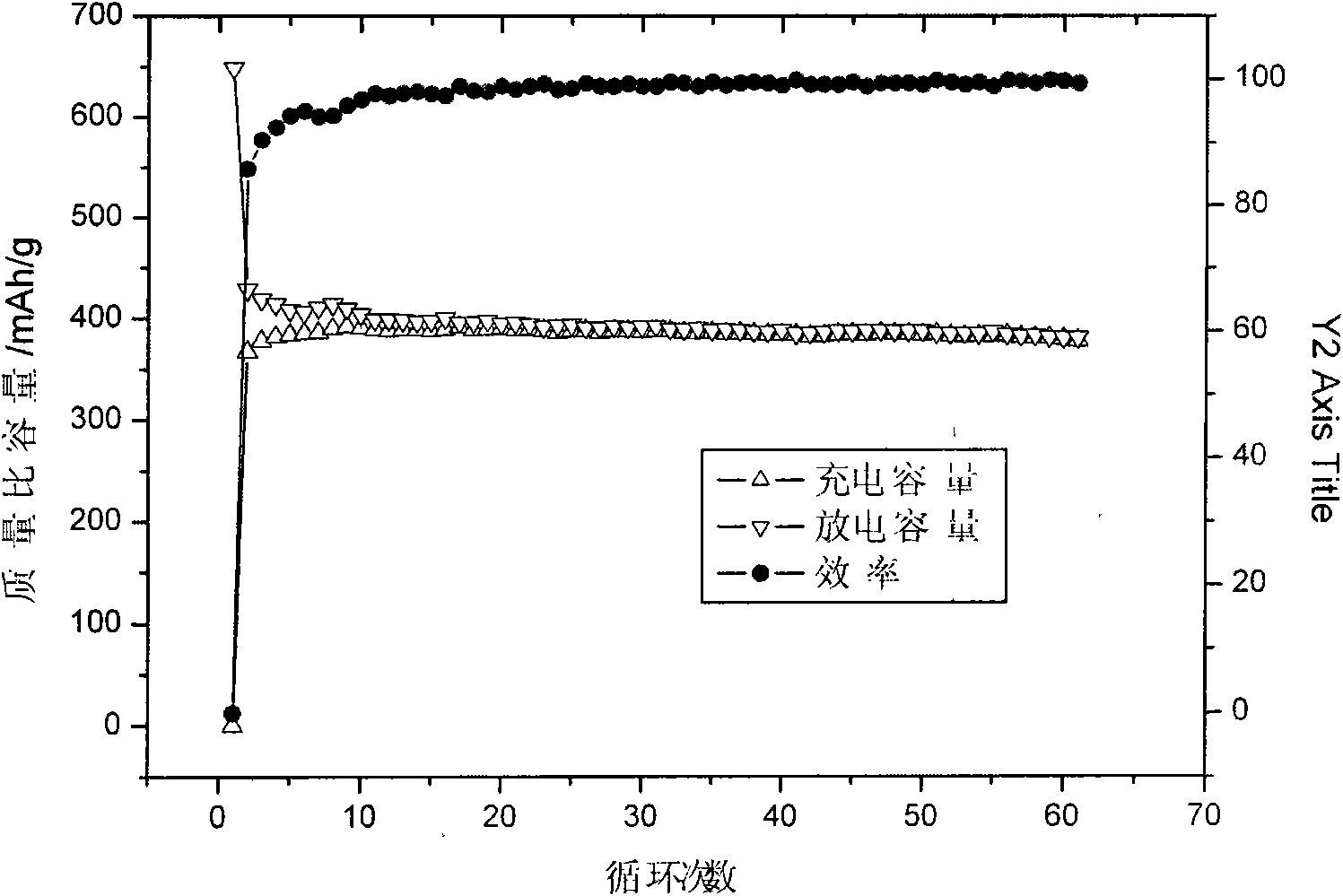

[0047] The tin-nickel-carbon alloy composite material for lithium-ion batteries is composed of 15% nickel powder, 20% tin powder, 58% graphite and 7% pitch, and the above percentages are all mass percentages.

[0048] The preparation method of the tin-nickel-carbon alloy composite material for lithium-ion batteries of the present embodiment is as follows:

[0049] (1) First mix 15% tin powder and 20% nickel powder according to the mass ratio and add appropriate amount of alcohol for high-energy mechanical ball milling for 10 hours;

[0050] (2) Then the alloy powder obtained by the above-mentioned mechanical ball milling was mixed with 58% graphite and alcohol was added to continue high-energy mechanical ball milling for 8 hours, and the particle size value of the added graphite was 15 μmm;

[0051] (3) Take out the above-mentioned tin-nickel alloy-carbon composite material to remove alcohol by suction filtration, then put it into an oven for vacuum drying for 8 hours, then ca...

no. 2 approach

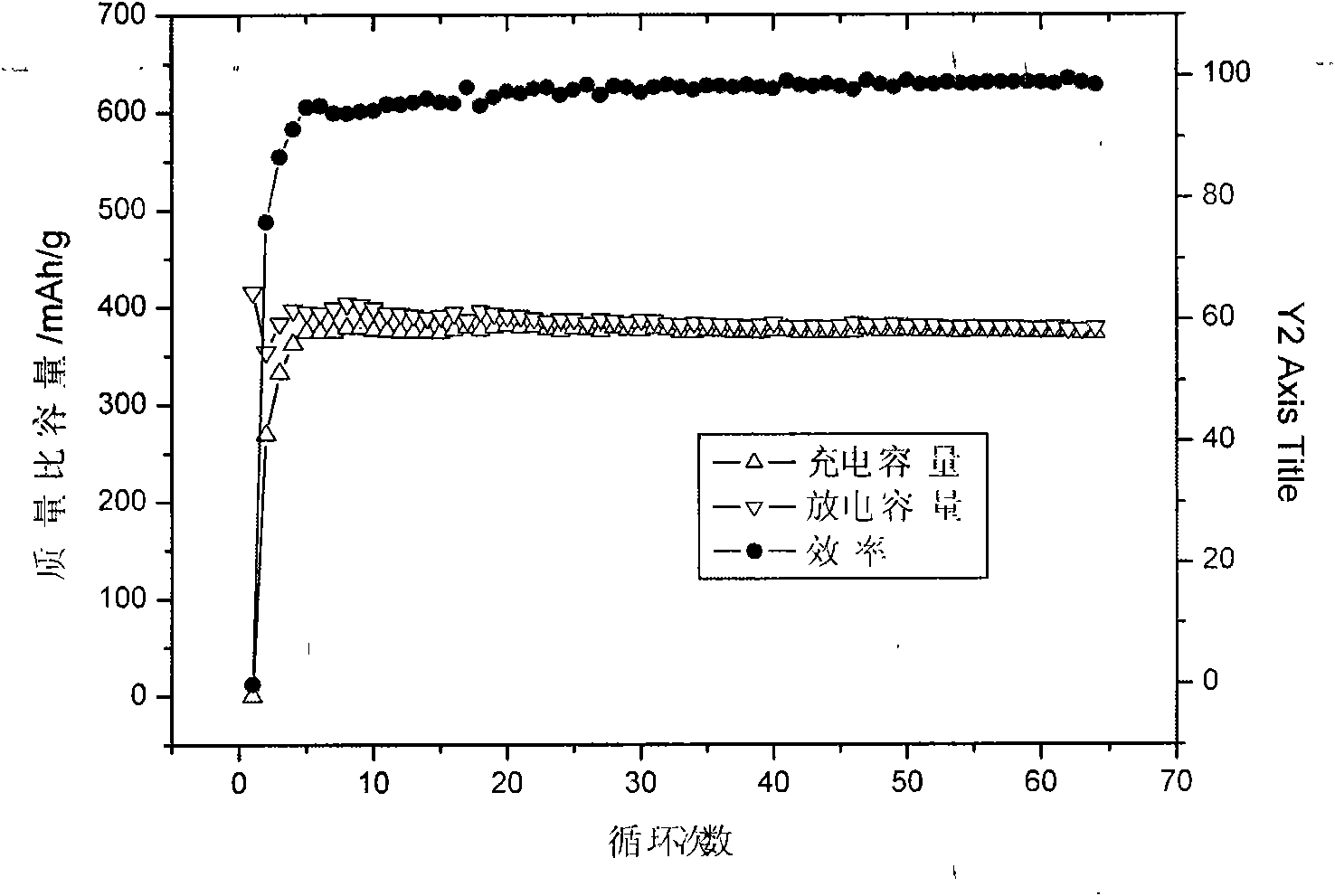

[0055] The tin-nickel-carbon alloy composite material for lithium-ion batteries is composed of 20% nickel powder, 25% tin powder, 45% graphite and 10% pitch, and the above percentages are all mass percentages.

[0056] The preparation method of the tin-nickel-carbon alloy composite material for lithium-ion batteries of the present embodiment is as follows:

[0057] (1) First, mix 20% tin powder and 25% nickel powder according to the mass ratio and add an appropriate amount of alcohol for high-energy mechanical ball milling for 12 hours;

[0058](2) Then the alloy powder obtained by above-mentioned mechanical ball milling was mixed with 45% graphite and alcohol was added to continue high-energy mechanical ball milling for 10 hours, and the particle size value of the added graphite was 17 μm;

[0059] (3) Take out the above-mentioned tin-nickel alloy carbon composite material to remove alcohol by suction filtration, then put it into an oven for vacuum drying for 12 hours, then p...

no. 3 approach

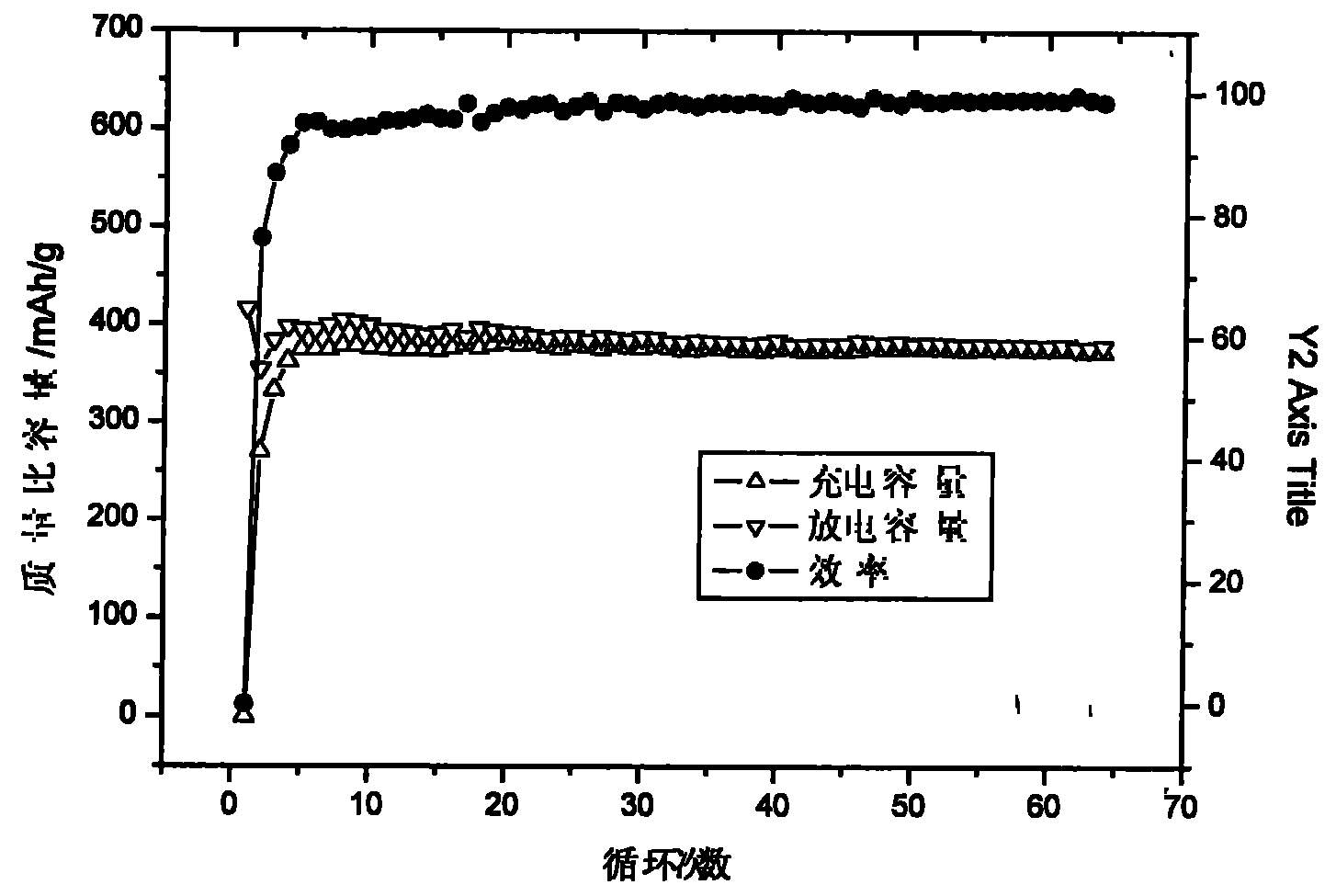

[0063] The tin-nickel-carbon alloy composite material for lithium-ion batteries is composed of 25% nickel powder, 30% tin powder, 35% graphite and 10% pitch, and the above percentages are all mass percentages.

[0064] The preparation method of the tin-nickel-carbon alloy composite material for lithium-ion batteries of the present embodiment is as follows:

[0065] (1) First mix 25% tin powder and 30% nickel powder according to the mass ratio and add appropriate amount of alcohol for high-energy mechanical ball milling for 15 hours;

[0066] (2) Then the alloy powder obtained by the above-mentioned mechanical ball milling was mixed with 35% graphite and alcohol was added to continue the high-energy mechanical ball milling for 15 hours, and the particle diameter value of the added graphite was 18 μmm;

[0067] (3) Take out the above-mentioned tin-nickel alloy carbon composite material to remove alcohol by suction filtration, then put it into an oven for vacuum drying for 16 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com