Negative electrode for power battery and power battery comprising same

A power battery and negative electrode technology, which is applied in the field of negative electrodes for power batteries, can solve the problems of reduced Coulombic efficiency, increased irreversible capacity for the first charge and discharge, and reduced battery life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

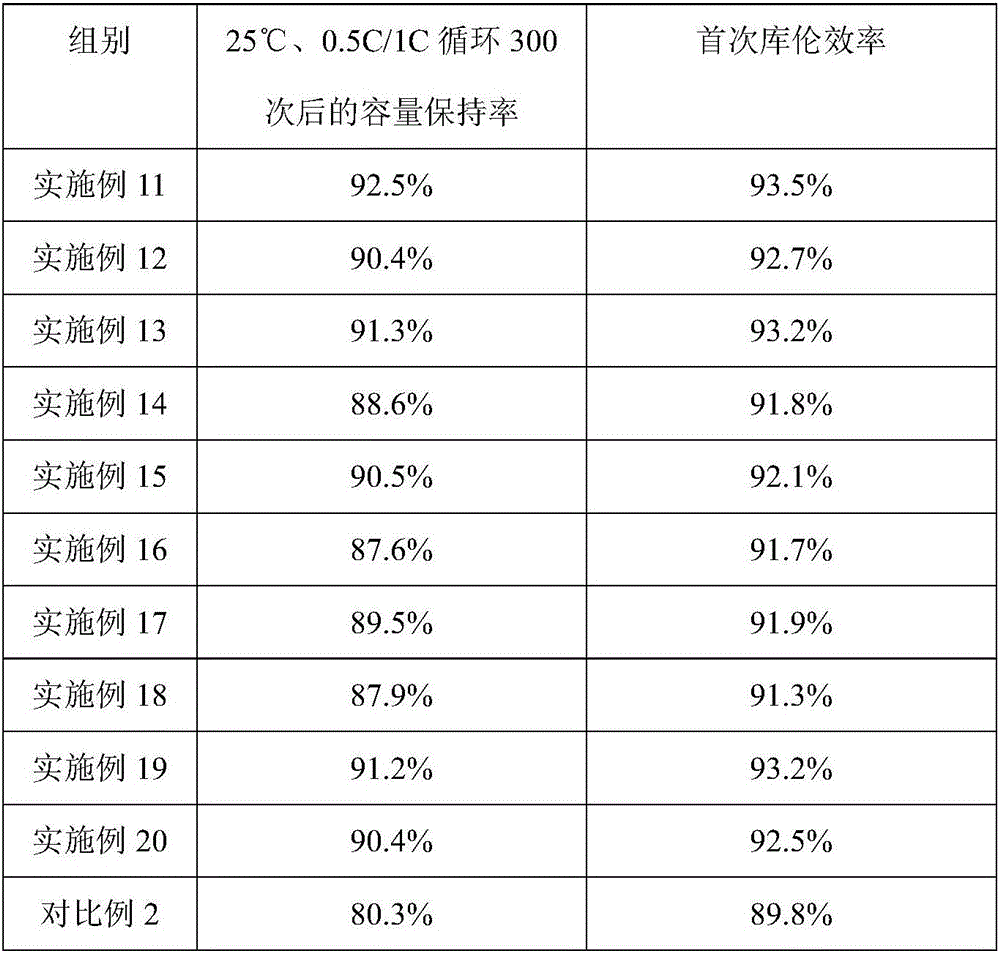

Examples

Embodiment 1

[0020] This embodiment provides a negative electrode for a power battery, including a negative electrode current collector and a negative electrode active material layer coated on the surface of the negative electrode current collector. The negative electrode active material layer includes graphite and a silicon carbon material dispersed in the gaps of the graphite, The proportion of graphite is 50%, and the particle size of graphite is 0.5 μm-100 μm; the silicon-carbon material is a silicon material coated with a porous carbon layer, the thickness of the porous carbon layer is 5 μm-90 μm, and the mass ratio of the porous carbon layer to the silicon-carbon material The porosity of the porous carbon layer is 30%, and the porosity of the porous carbon layer is 45%.

[0021] The surface of the negative electrode active material layer is provided with a SEI-like film coating layer. In terms of mass percentage, the composition of the SEI-like film coating layer is: 80% amorphous car...

Embodiment 2

[0023] The difference with embodiment 1 is:

[0024] The negative electrode active material layer includes graphite and silicon-carbon material dispersed in the gaps of graphite. The proportion of graphite is 60%. The mass ratio of the layer to the silicon-carbon material is 20%, and the porosity of the porous carbon layer is 60%.

[0025] The composition of the SEI-like film coating layer is: 70% amorphous carbon, 10% lithium carbonate, 10% alkyl lithium carbonate, 9.3% lithium fluoride and 0.7% binder styrene-butadiene rubber, SEI-like The thickness of the film coating layer was 10 μm.

[0026] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0028] The difference with embodiment 1 is:

[0029] The negative electrode active material layer includes graphite and silicon-carbon material dispersed in the gaps of graphite, the proportion of graphite is 80%; the silicon-carbon material is a silicon material coated with a porous carbon layer, and the thickness of the porous carbon layer is 5 μm-90 μm. The mass ratio of the layer to the silicon-carbon material is 25%, and the porosity of the porous carbon layer is 30%.

[0030]The composition of the SEI-like film coating layer is: 50% amorphous carbon, 20% lithium carbonate, 18.5% alkyl lithium carbonate, 10% lithium fluoride and 1.5% binder sodium alginate, SEI-like The thickness of the film coating layer was 25 μm.

[0031] In the preparation method of the SEI-like film coating layer, deionized water is replaced by ethanol, spraying is replaced by transfer printing, and the temperature of heat treatment is 80°C.

[0032] The rest are the same as in Embodiment 1, and wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com