Lithium-rich positive electrode material surface modification method, positive electrode containing surface-modified lithium-rich positive electrode material, and lithium ion battery

A lithium-rich positive electrode material, lithium-ion battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance and rate performance, low Coulombic efficiency and rate performance, and insignificant improvement in electrical performance, etc. Achieve environmental friendliness, improve electrical performance, and increase the effect of the first discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

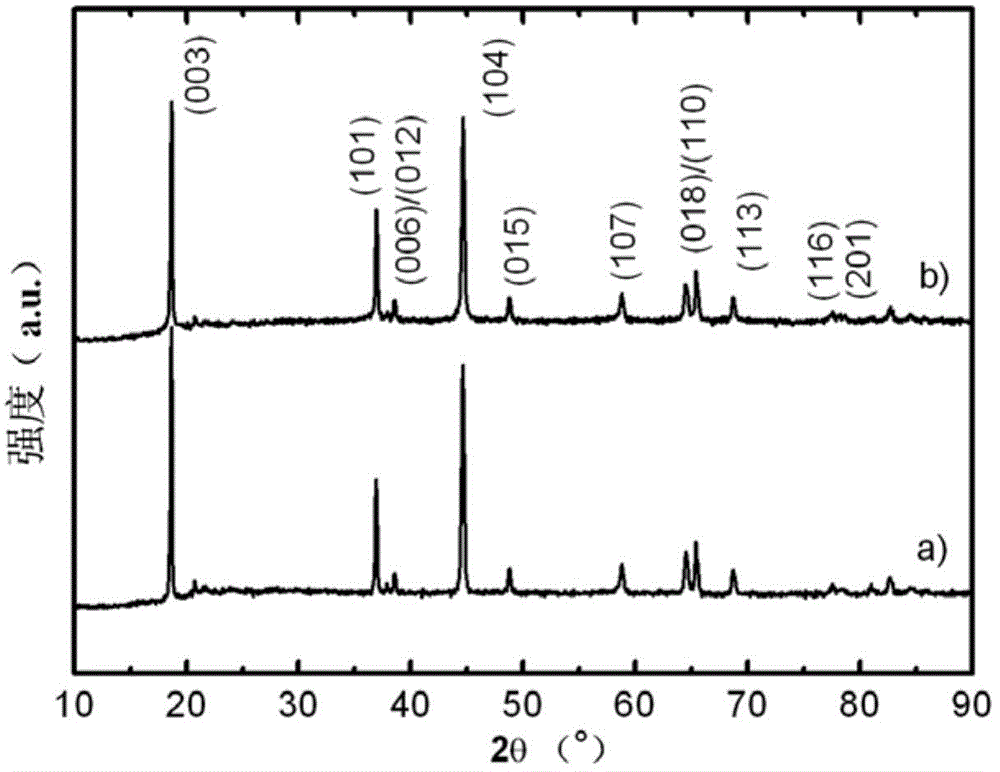

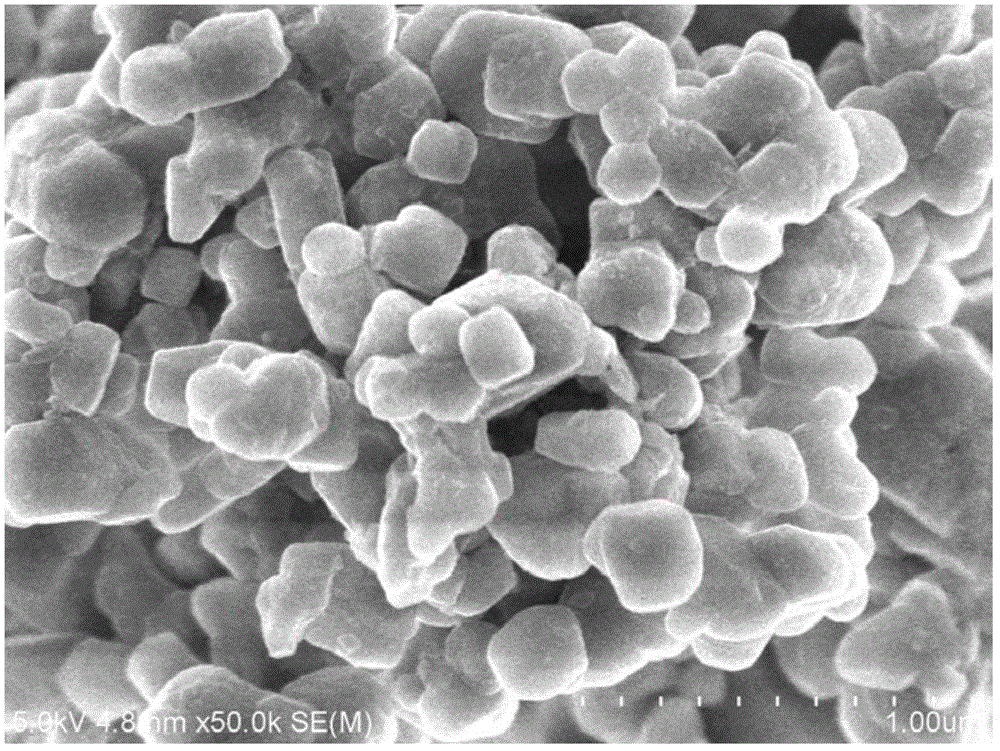

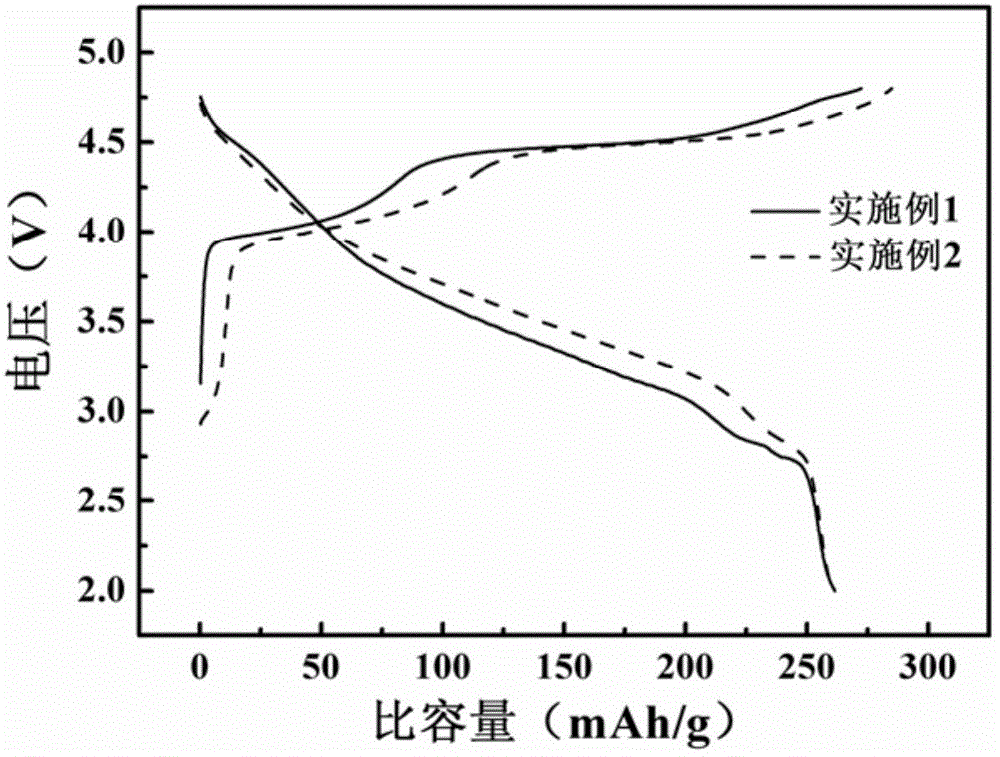

[0028] Weigh the composition as 0.6Li 2 O 0.8Mn 0.675 Ni 0.1625 co 0.1625 o1.75 30.00 g of the lithium-rich cathode material was dispersed in 500 mL of 0.01 mol / L hydrochloric acid solution, heated and stirred at 80° C. for 5 h, and evaporated to dryness. The dried powder was heat treated at 200°C and kept for 10h. The obtained powder was washed with deionized water, filtered with suction and dried, and dispersed in 2.68g of Al(NO 3 ) 3 in aqueous solution (with coating AlF 3 Calculated, its relative lithium-rich cathode material addition is 2wt%), continue to stir, add ammonia water dropwise to make the slurry pH = 7, NH 4 An aqueous solution of F (0.79 g) was added to the above slurry, the stirring was continued for 6 h, and the slurry was dried at 100°C. Afterwards, the powder was heat-treated at 450°C under an argon atmosphere, kept for 8 hours, and cooled with the furnace. The obtained powder is ground and passed through a 300-mesh sieve to finally obtain a surfac...

Embodiment 2

[0030] Weigh the composition as 0.6Li 2 O 0.8Mn 0.7 Ni 0.2 co 0.1 o 1.75 30.00g of lithium-rich cathode material, dispersed in 500mL of 10 -6 mol / L sulfuric acid solution, heated and stirred at 70°C for 6 hours, and evaporated to dryness. The dried powder is heat treated at 400°C and kept for 10h. The obtained powder was washed with deionized water, suction filtered and dried, and then dispersed in dissolved 0.67g Al(NO 3 ) 3 in aqueous solution (with coating AlF 3 Calculated, its relative addition amount of lithium-rich cathode material is 0.5wt%), continuous stirring, dripping ammonia water to make the slurry pH = 7, NH 4 F (0.20g) aqueous solution was added to the above slurry, and the stirring reaction was continued for 6h, and the slurry was dried at 100°C. Afterwards, the powder was heat-treated at 450°C under an argon atmosphere, kept for 8 hours, and cooled with the furnace. The obtained powder is ground and passed through a 300-mesh sieve to finally obtain a...

Embodiment 3

[0032] Weigh the composition as 0.6Li 2 O 0.8Mn 0.675 Ni 0.1625 co 0.1625 o 1.75 30.00g of lithium-rich cathode material, dispersed in 500mL of 10 -6 mol / L nitric acid solution, heated and stirred at 90°C for 5h, and evaporated to dryness. The dried powder was heat-treated at 500°C and kept for 10 hours. The obtained powder was washed with deionized water, filtered with suction and dried, and then dispersed in dissolved 0.44gSr(NO 3 ) 2 in aqueous solution (with coating SrF 2 Calculated, its relative addition amount of lithium-rich positive electrode material is 1wt%), continuous stirring, dripping ammonia water to make the slurry pH = 7, NH 4 An aqueous solution of F (0.15 g) was added to the above slurry, the stirring was continued for 4 h, and the slurry was dried at 100°C. Afterwards, the powder was heat-treated at 550°C under an argon atmosphere, kept for 8 hours, and cooled with the furnace. The obtained powder is ground and passed through a 300-mesh sieve to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com