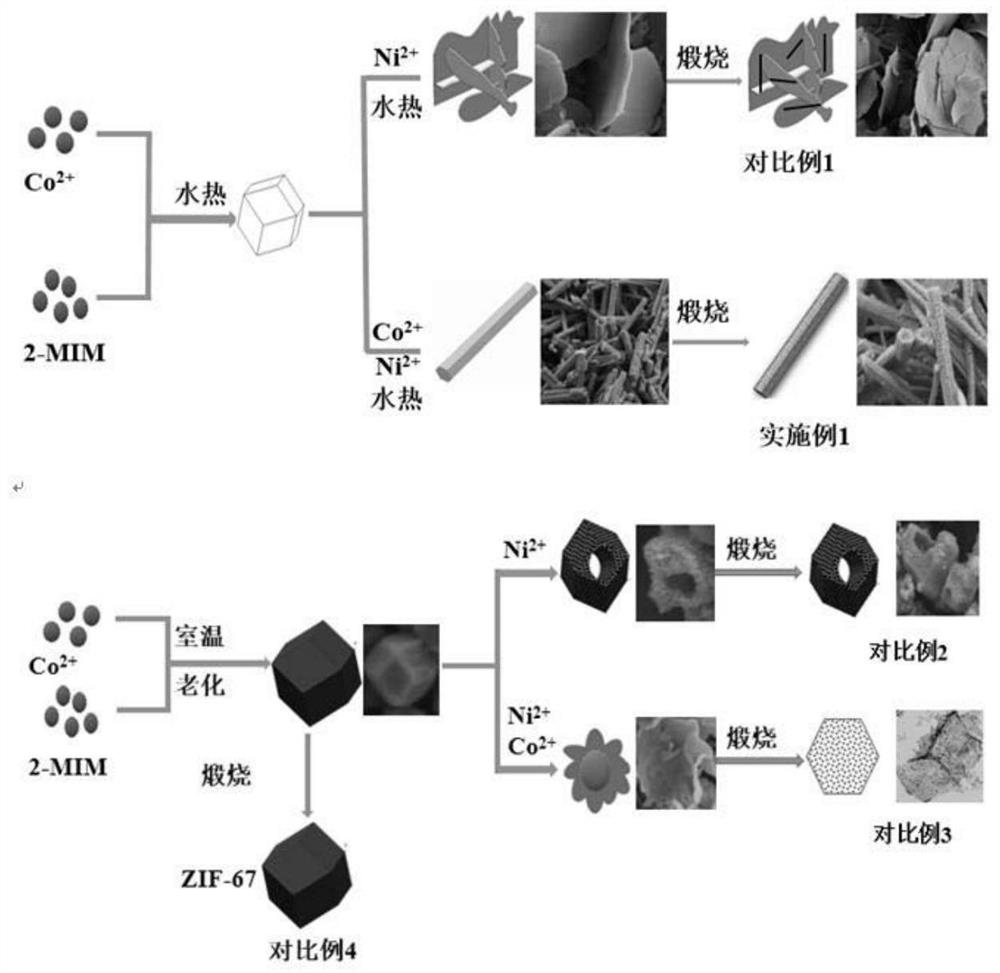

Preparation method and application of nanorod-like NiCo2O4 material

A nanorod-like, preparation process technology, applied in the field of nanomaterials, can solve the problems of hindering the electron transfer level between active materials and electrodes, hindering the electron transfer of MOF particles, poor conductivity of MOF materials, etc. The effect of simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Nanorod material NiCo 2 o 4 -1 preparation method, comprises the following steps:

[0028] (1) Preparation of Co-ZIF: Weigh 2.9g of cobalt nitrate and 3.3g of 2-methylimidazole respectively dissolved in 20mL of methanol solution, then mix them into a 50mL autoclave and keep at 100°C for 12h. Finally, wash with deionized water and ethanol and dry at 60°C for 12 hours;

[0029] (2) Preparation of precursor: Weigh 0.2g Co-ZIF, 0.2908g nickel nitrate, 0.5821g cobalt nitrate and 0.3003g urea into 35mL deionized water, put them into a 50mL autoclave and keep at 120°C for 12h. After centrifugation, wash with water and ethanol, and dry at 60°C for 12 hours;

[0030] (3) Sample preparation: the precursor was placed in a porcelain boat, heated from room temperature to 350 °C at a rate of 1 °C / min in an air atmosphere, calcined for 2 h, and naturally cooled to room temperature to prepare the sample.

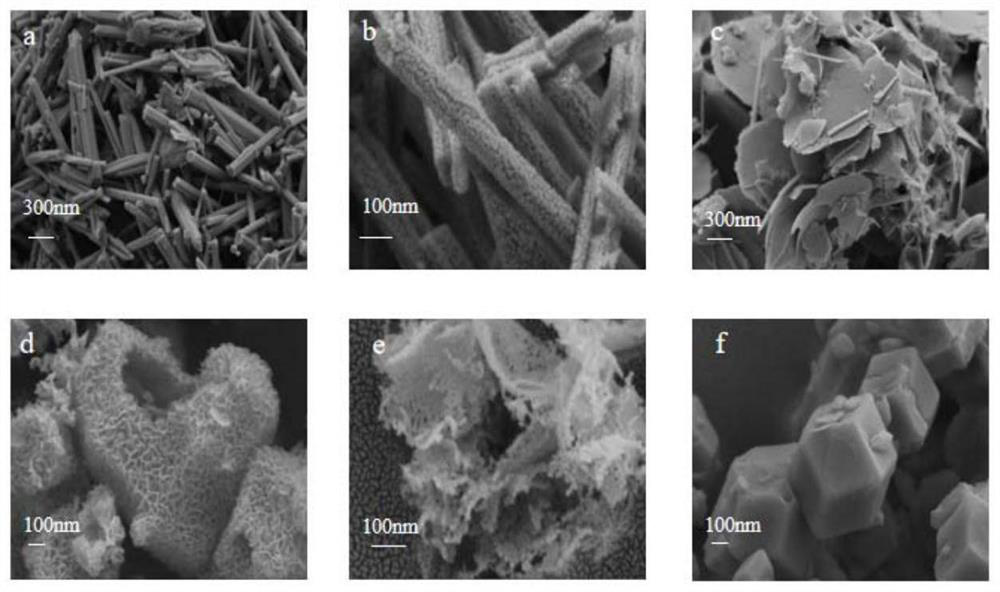

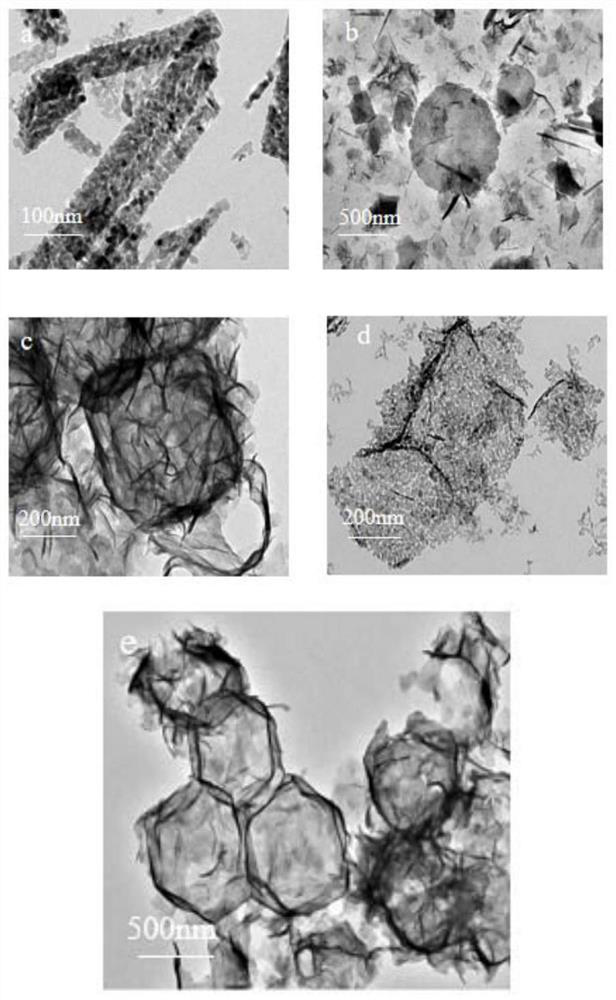

[0031] figure 2 (a) NiCo made for this example 2 o 4 SEM photo of -1 (un...

Embodiment 2

[0033] Nanorod material NiCo 2 o 4 The preparation method comprises the following steps:

[0034] (1) Preparation of Co-ZIF: Weigh 2.9g of cobalt nitrate and 3.3g of 2-methylimidazole respectively dissolved in 20mL of methanol solution, put them in a 50mL autoclave at 100°C for 12h, and use deionized After washing with water and ethanol, dry at 60°C for 12 hours;

[0035](2) Preparation of precursor: Weigh 0.2g of Co-ZIF, 0.1454g of nickel nitrate, 0.5821g of cobalt nitrate and 0.3003g of urea into 35mL of deionized water, put them into a 50mL autoclave and keep at 120°C for 6h. After centrifugation, wash with water and ethanol, and dry at 60°C for 12 hours; after centrifugation, wash with water and ethanol, and dry at 60°C for 12 hours;

[0036] (3) Sample preparation: the precursor was placed in a porcelain boat, heated from room temperature to 300 °C at a rate of 1 °C / min in an air atmosphere, calcined for 4 h, and cooled naturally to room temperature to prepare the samp...

Embodiment 3

[0038] Nanorod material NiCo 2 o 4 The preparation method comprises the following steps:

[0039] (1) Preparation of Co-ZIF: Weigh 2.9g of cobalt nitrate and 3.3g of 2-methylimidazole respectively dissolved in 20mL of methanol solution, put them in a 50mL autoclave at 120°C for 6h, and use deionized After washing with water and ethanol, dry at 60°C for 12 hours;

[0040] (2) Preparation of precursor: Weigh 0.2g of Co-ZIF, 0.2908g of nickel nitrate, 0.2908g of cobalt nitrate and 0.3003g of urea into 35mL of deionized water, put them into a 50mL autoclave and keep at 60°C for 24h. After being collected by centrifugation, it was washed with water and ethanol, and dried at 60°C for 12 hours. After centrifugation, wash with water and ethanol, and dry at 60°C for 12 hours;

[0041] (3) Sample preparation: the precursor was placed in a porcelain boat, heated from room temperature to 400 °C at a rate of 1 °C / min in air, calcined for 2 h, and cooled naturally to room temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com