Graphitized carbon-coated porous carbon sphere with high specific surface area as well as preparation method and application thereof

A high specific surface area, graphitized carbon technology, applied in electrochemical generators, active material electrodes, electrical components, etc., can solve the problems of low energy density of negative electrode materials, poor cycle performance, limited sodium storage active sites, etc. To achieve good effect, prevent collapse, optimize the effect of sodium storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Pour ammonia water, absolute ethanol and distilled water into a three-necked flask at a volume ratio of 1:80:200, stir and mix evenly to obtain solution A.

[0035] 2. Add 0.2g of resorcinol into solution A, stir until it is completely dissolved to obtain solution B. Then add 0.28mL of formaldehyde into solution B, stir, and heat in a water bath at 100°C for 24h to obtain a phenolic resin polymer solution. The phenolic resin polymer solution was hydrothermally reacted at 100° C. for 24 hours, centrifuged, filtered, washed and dried to obtain phenolic resin nanospheres.

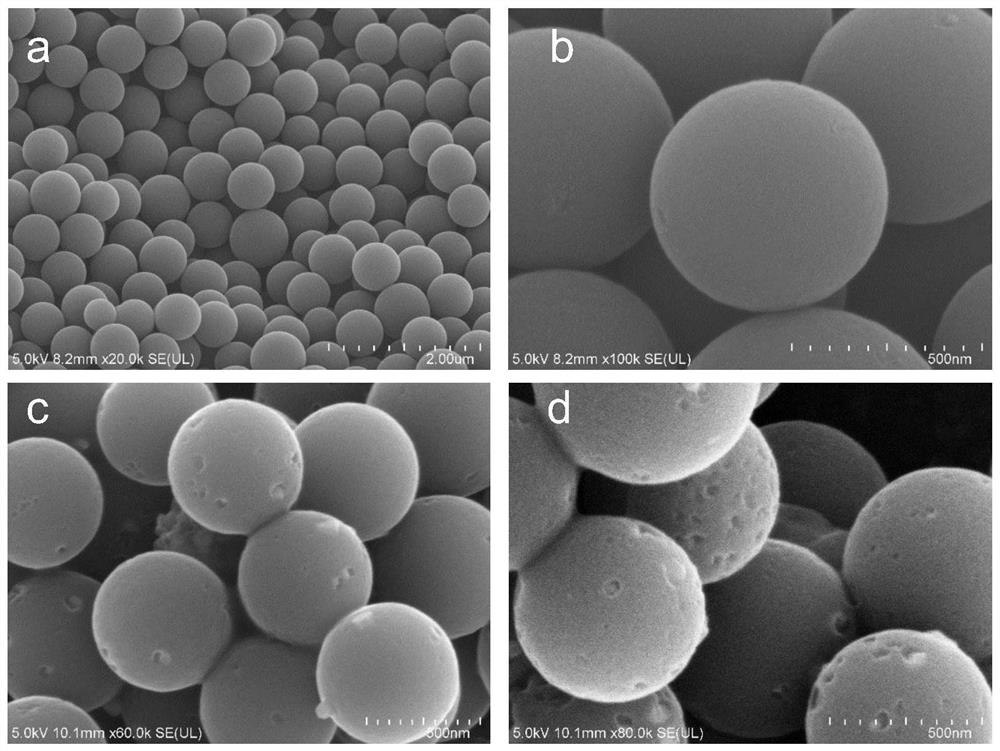

[0036] 3. The phenolic resin nanospheres were placed in a tube furnace in a nitrogen atmosphere and calcined at 800° C. to prepare carbon nanospheres (CS).

[0037] 4. KOH was used as the activator, and CS was activated to form pores according to the mass ratio of CS:KOH of 1:1. After the reaction, excess KOH was washed away and dried to obtain high specific surface area carbon nanospheres (HSCS). ...

Embodiment 2

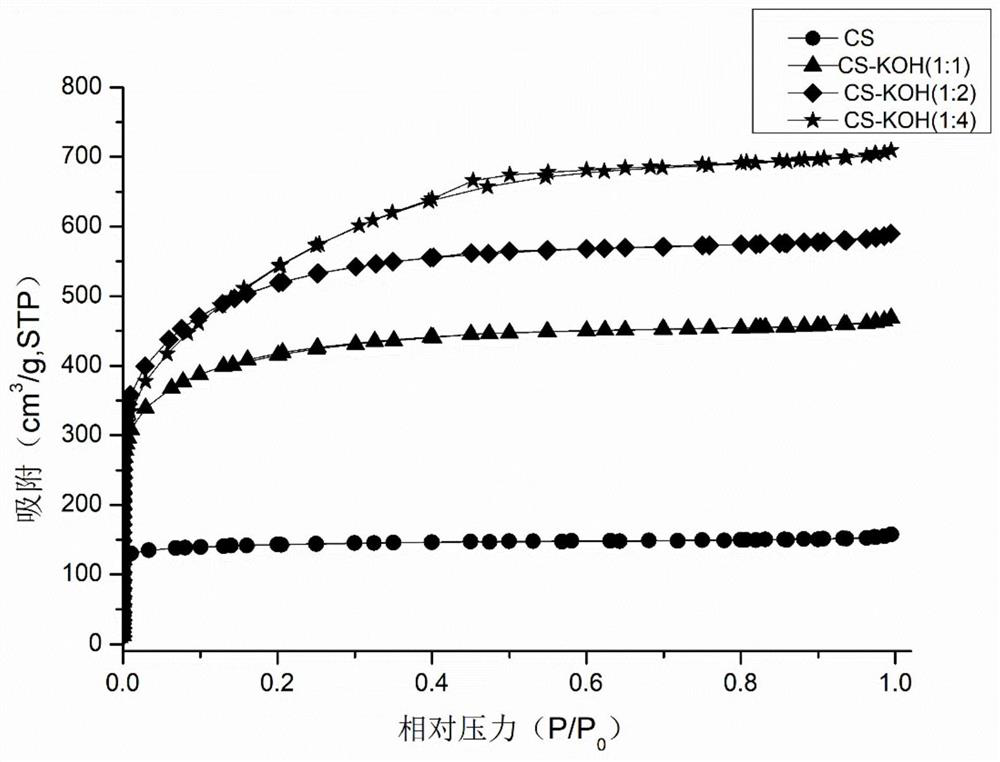

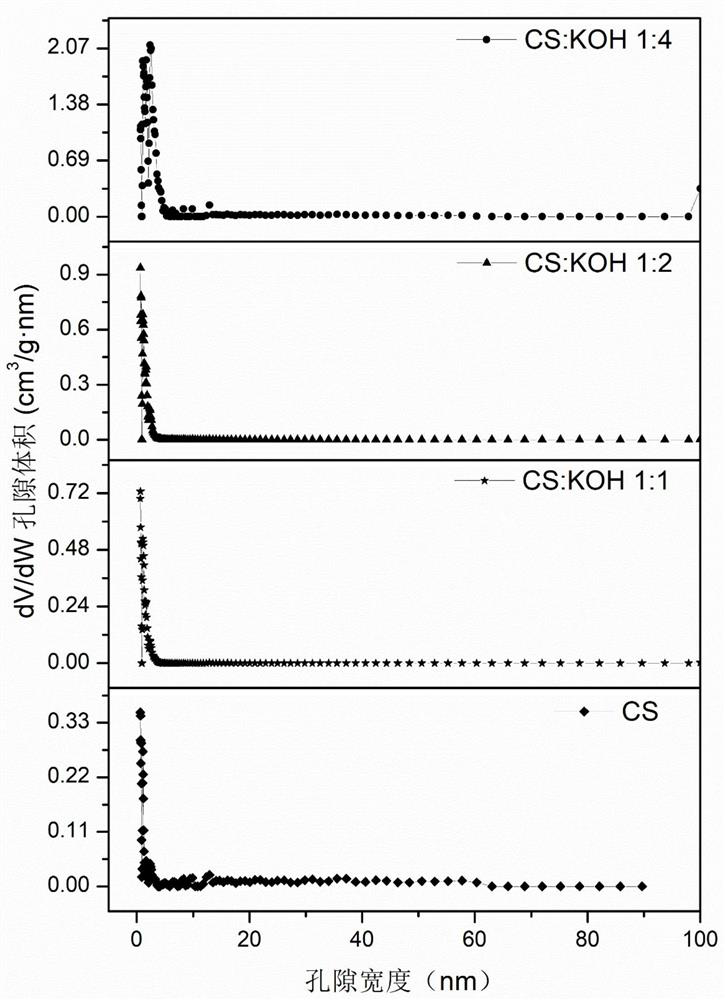

[0042] Table 1 for g at 200mA -1 The effect of activated mass ratio (CS:KOH) on the electrochemical performance of electrode materials under constant current charge and discharge. The difference from Example 1 is that the mass ratio of CS to KOH is different. It can be seen from Table 1 that as the mass ratio of CS and KOH increases, the specific capacity of the first charge and discharge increases, but the efficiency value is basically in a stable state.

[0043] Table 1 Effect of (CS:KOH) mass ratio on the electrochemical performance of electrode materials

[0044]

Embodiment 3

[0046] Table 2 for g at 200mA -1 Effect of carbon coating on the electrochemical performance of materials under constant current charge and discharge conditions. The difference from Example 2 is that no nickelocene is used to coat the carbon. It can be seen from Table 2 that the increase in the mass ratio of CS and KOH brings about a larger change in the first discharge specific capacity than the first charge specific capacity, which leads to a decrease in the efficiency value.

[0047] Table 2 Effect of carbon coating on the electrochemical performance of electrode materials

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com