Preparation method of composite hard carbon sodium-ion battery cathode material

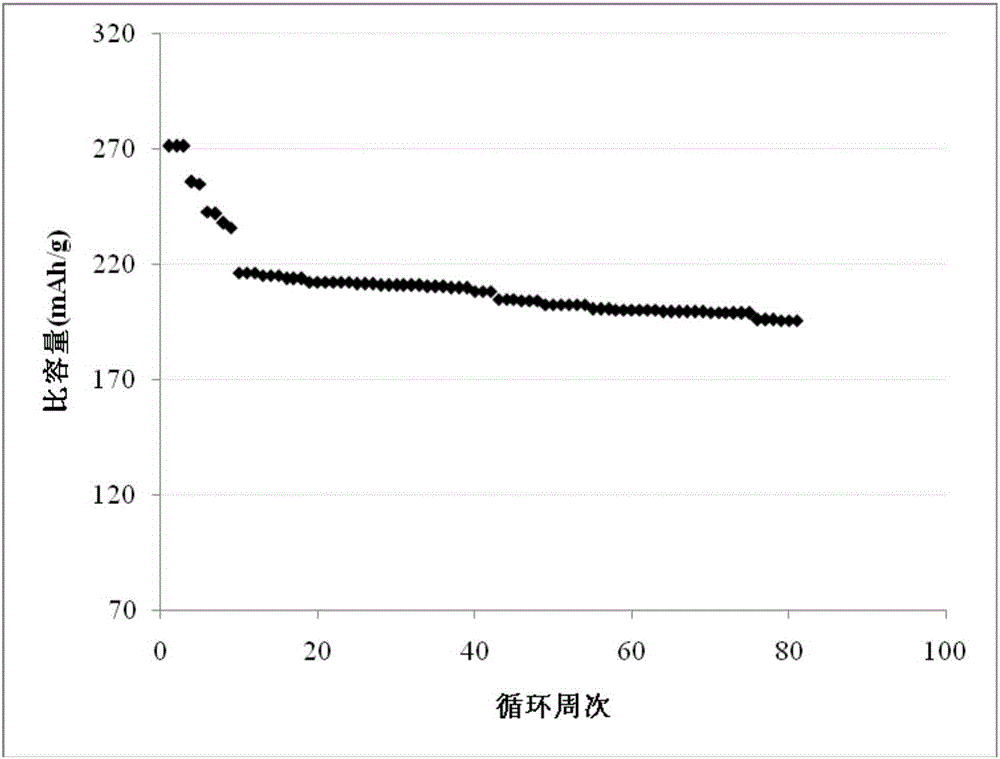

A sodium-ion battery and negative electrode material technology, applied in the field of electrochemical materials, can solve problems such as poor cycle stability, large irreversible capacity, and poor rate performance, and achieve stable product properties, improve cycle stability, and improve liquid absorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

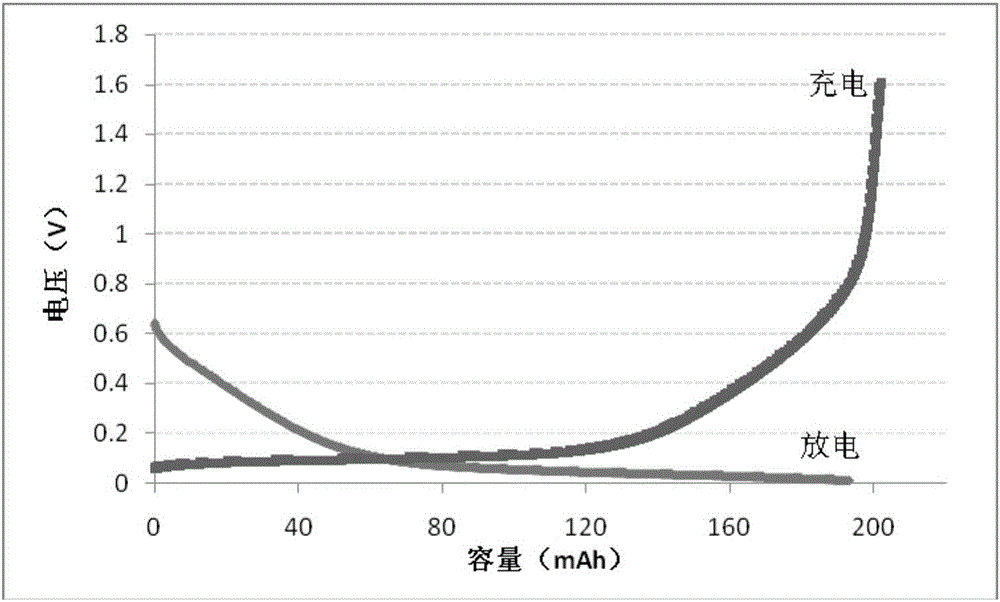

Embodiment 1

[0029] Embodiment 1: The preparation method of the composite hard carbon sodium ion battery negative electrode material provided by this embodiment comprises the following steps:

[0030] S1: Boron-doped hard carbon and carbon source precursor are mixed and ball-milled at a mass ratio of 9.5:0.5, wherein the boron-doped hard carbon has a particle size of 10-20um and a specific surface area of 4-4.2m 2 / g, tap density 0.9~1g / cm 3 , the carbon source precursor is cross-linked starch microspheres, the ball milling time is 2 hours, and the rotation speed is 150r / min;

[0031] S2: Calcining the semi-finished product after mixed ball milling at a high temperature in a protective atmosphere, wherein the calcination temperature is 900° C., and the calcination time is 20 hours, to prepare a composite hard carbon sodium ion battery negative electrode material.

[0032] Specifically, boron-doped hard carbon is prepared by the following steps:

[0033] Disperse thermoplastic phenolic ...

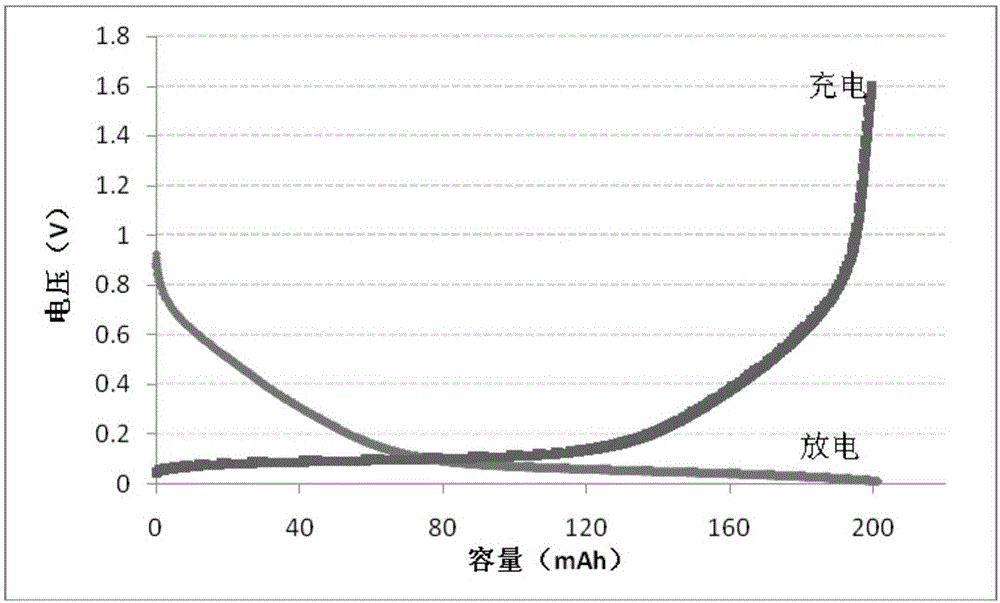

Embodiment 2

[0039]Embodiment 2: the preparation method of the composite hard carbon sodium ion battery negative electrode material that this embodiment provides, it is basically the same as embodiment 1, and difference is:

[0040] S1: Boron-doped hard carbon and carbon source precursor are mixed and ball-milled at a mass ratio of 9.0:1, wherein the boron-doped hard carbon has a particle size of 10-20um and a specific surface area of 4-4.2m 2 / g, tap density 0.9~1g / cm 3 , the carbon source precursor is cross-linked starch microspheres, the ball milling time is 4 hours, and the rotation speed is 300r / min;

[0041] S2: Calcining the semi-finished product after mixed ball milling at high temperature in a protective atmosphere, wherein the calcination temperature is 1100° C., and the calcination time is 4 hours, to prepare a composite hard carbon sodium ion battery negative electrode material.

[0042] Specifically, boron-doped hard carbon is prepared by the following steps:

[0043] Disp...

Embodiment 3

[0047] Embodiment 3: the preparation method of the composite hard carbon sodium ion battery negative electrode material that this embodiment provides, it is basically the same as embodiment 1, and difference is:

[0048] S1: Boron-doped hard carbon and carbon source precursor are mixed and ball-milled at a mass ratio of 8.5:1.5, wherein the boron-doped hard carbon has a particle size of 10-20um and a specific surface area of 4-4.2m 2 / g, tap density 0.9~1g / cm 3 , the carbon source precursor is cross-linked starch microspheres, the ball milling time is 3 hours, and the rotation speed is 200r / min;

[0049] S2: Calcining the semi-finished product after mixed ball milling at high temperature in a protective atmosphere, wherein the calcination temperature is 1000° C. and the calcination time is 12 hours, to prepare a composite hard carbon sodium ion battery negative electrode material.

[0050] Specifically, boron-doped hard carbon is prepared by the following steps:

[0051] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com