Porous graphene and preparation method therefor

A technology of porous graphene and graphene, which is applied in the field of graphene materials, can solve the problems of expensive transition metals, increased costs, complex processes, etc., and achieve the effect of simple and easy preparation method, low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

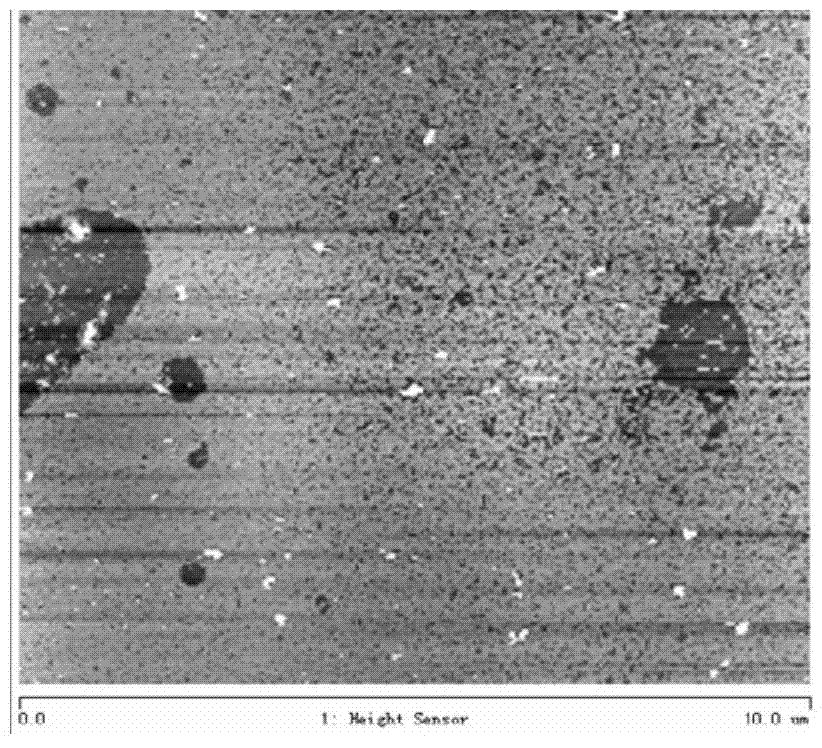

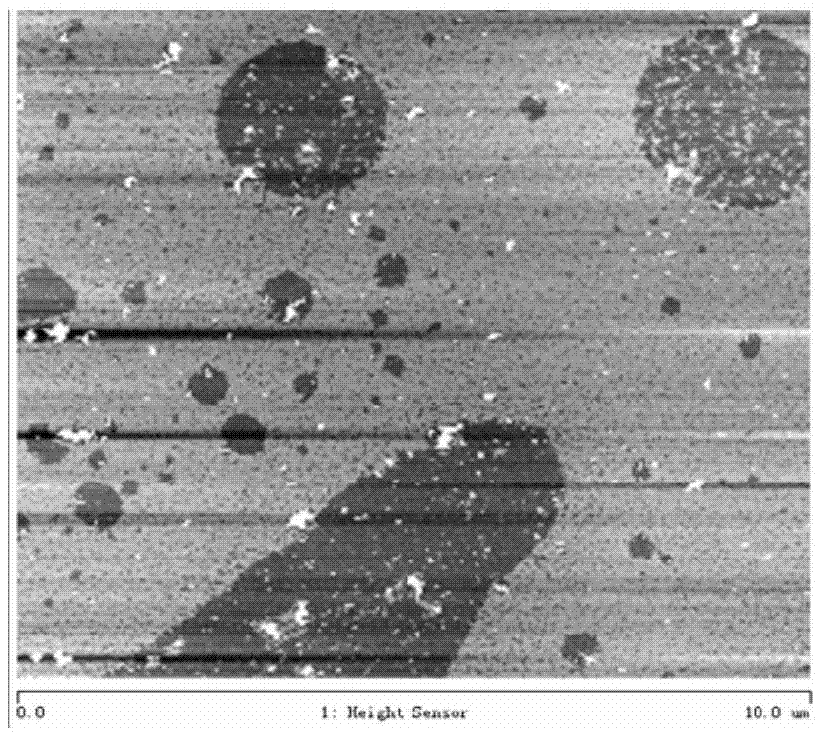

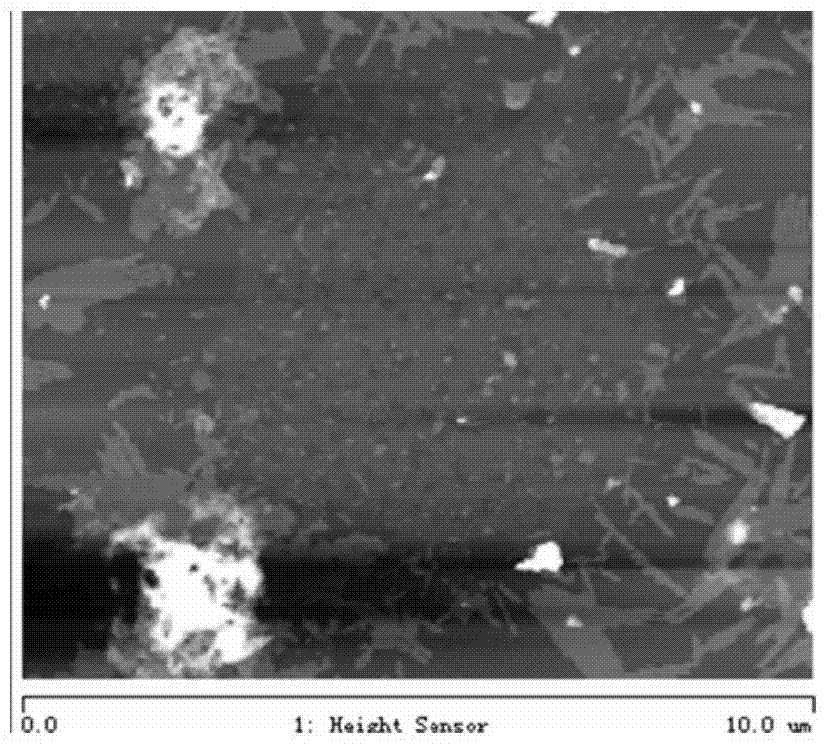

Image

Examples

Embodiment 1

[0023] Prepare an acetic acid aqueous solution with a volume concentration of 0.5%, and set the weight average molecular weight to 5.0×10 3 , Chitosan with a degree of deacetylation of 40% is dissolved in an aqueous acetic acid solution to prepare a chitosan solution with a mass concentration of 0.1 mg / mL, and stir evenly;

[0024] Add graphite to the above chitosan solution, and control the mass ratio of chitosan to graphite to 1:10;

[0025] The above-mentioned mixed liquid was put into an ultrasonic cleaner for ultrasonic treatment, the temperature was 75° C., the time was 0.5 hours, and the ultrasonic power was 600 W.

[0026] After centrifuging the above-mentioned ultrasonic solution at 1000 rpm for 10 minutes, the above-mentioned acetic acid aqueous solution was used for centrifugal cleaning at 15000 rpm, and the centrifugation time was 0.5 hours.

Embodiment 2

[0028] Prepare an aqueous acetic acid solution with a volume concentration of 2%, and set the weight average molecular weight to 2.0×10 4 , Chitosan with a degree of deacetylation of 53% is dissolved in an aqueous acetic acid solution to prepare a chitosan solution with a mass concentration of 0.2mg / mL, and stir evenly;

[0029] Add graphite to the above chitosan solution, and control the mass ratio of chitosan to graphite to 1:5;

[0030] The above-mentioned mixed liquid was put into an ultrasonic cleaner for ultrasonic treatment, the temperature was 60°C, the time was 2 hours, and the ultrasonic power was 540W.

[0031] After centrifuging the above-mentioned ultrasonic solution at 2000 rpm for 10 minutes, the above-mentioned aqueous acetic acid solution was used for centrifugal cleaning at 20000 rpm, and the centrifugation time was 1 hour.

Embodiment 3

[0033] Prepare an aqueous solution of acetic acid with a volume concentration of 4%, and set the weight average molecular weight to 1.5×10 5 , Chitosan with a degree of deacetylation of 60% is dissolved in an aqueous acetic acid solution to prepare a chitosan solution with a mass concentration of 0.5 mg / mL, and stir evenly;

[0034] Add graphite to the above chitosan solution, and control the mass ratio of chitosan to graphite to 1:1;

[0035] The above-mentioned mixed liquid was put into an ultrasonic cleaner for ultrasonic treatment, the temperature was 30°C, the time was 8 hours, and the ultrasonic power was 480W.

[0036] After centrifuging the above-mentioned ultrasonic solution at 2000 rpm for 5 minutes, the above-mentioned aqueous acetic acid solution was used for centrifugal cleaning at 16000 rpm, and the centrifugation time was 1.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com