Preparation method of nitrogen, phosphorus and oxygen co-doped porous graphitized carbon nanosheet

A technology of porous graphite and carbon nanosheets, which is applied in the preparation of oxygen co-doped porous graphitized carbon nanosheets, phosphorus and nitrogen fields, can solve the problems of cumbersome preparation process of carbon nanosheets, unreasonable pore distribution and poor electrical conductivity. , to achieve the effect of good conductivity, low cost and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 1 g of phytic acid and dissolve it in 10 mL of deionized water, then add 10 mL of 0.05 g / mL ferric nitrate solution dropwise into the phytic acid solution under stirring, and after stirring continuously for 1 hour, add 0.05 g The melamine sponge was added to the above mixed solution, stirred to make it fully impregnated, and the self-assembled iron-phytic acid complex was obtained through the complexation of metal ions and phytic acid, and then dried in an oven at 80°C.

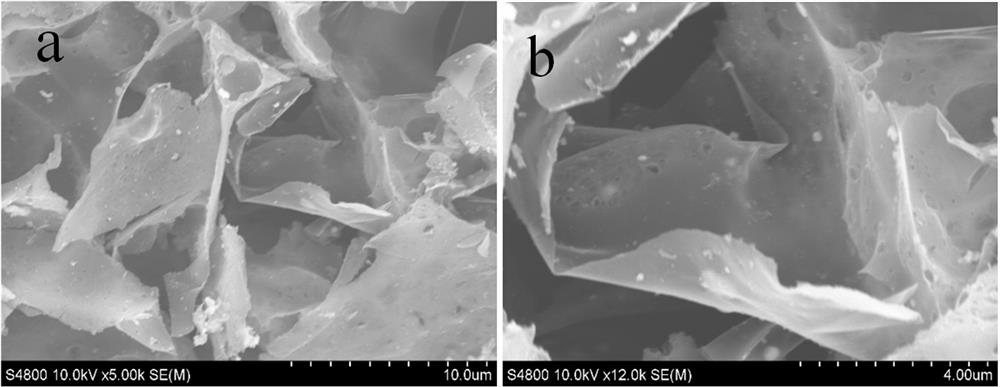

[0027] (2) Carbonize the dried solid in a nitrogen atmosphere, raise the temperature to 700°C at a rate of 5°C / min, keep it warm for 1 hour, cool naturally, and wash repeatedly with acid and deionized water to remove metals in the product elements, and then dried at 80°C to obtain the porous graphitized carbon nanosheets.

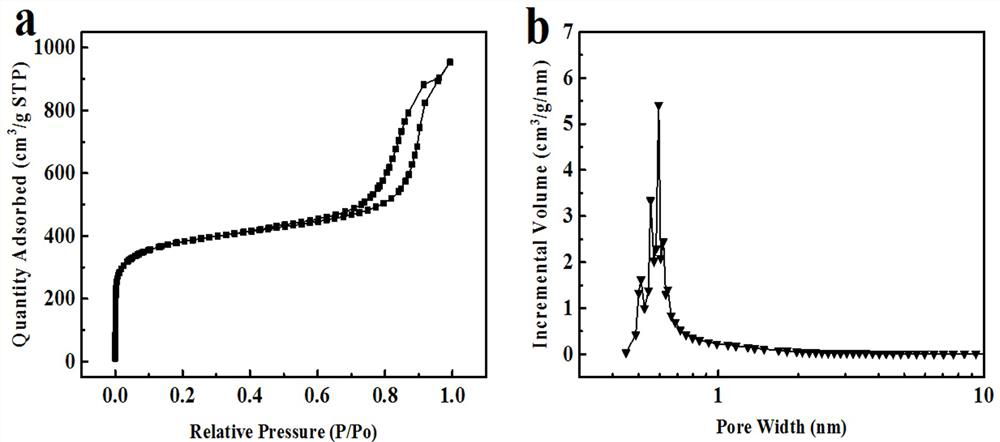

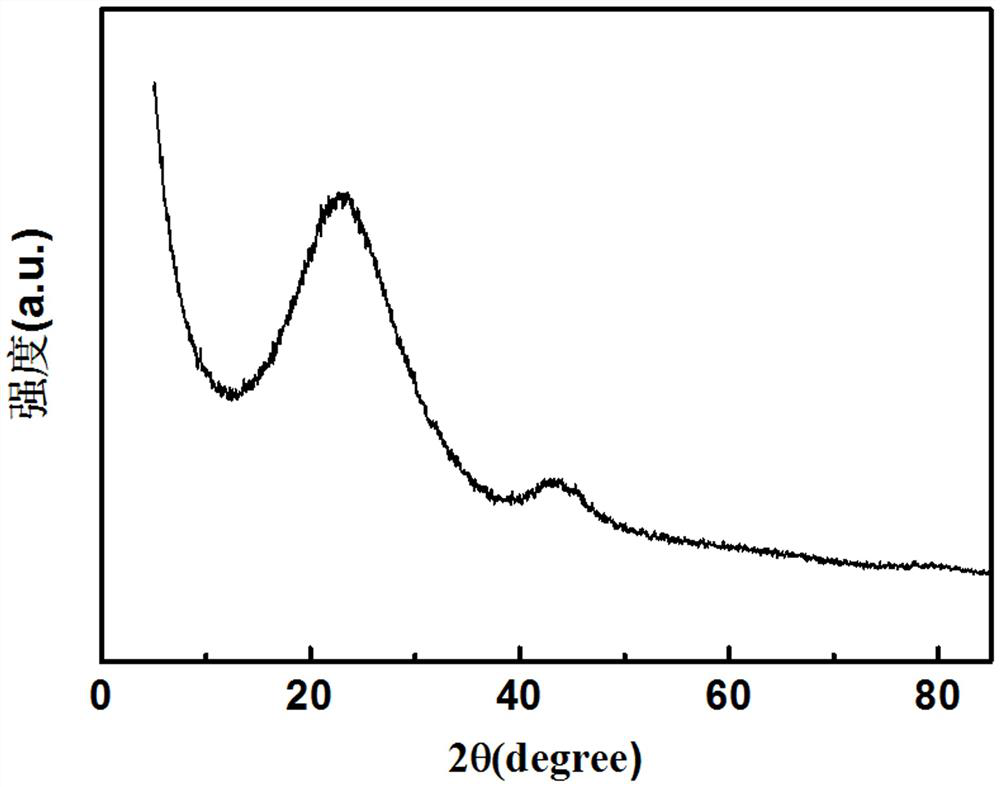

[0028] The prepared carbon nanosheets were measured by D / max-2500 X-ray diffractometer. The corresponding test conditions and parameters were: Cu target, Ni filter materia...

Embodiment 2

[0031] (1) Weigh 1 g of sodium phytate and dissolve it in 10 mL of deionized water, then add 10 mL of 0.1 g / mL potassium ferricyanide solution dropwise into the sodium phytate solution under stirring, and continue stirring for 1 hour , add 0.1 g melamine sponge to the above mixed solution, stir to make it fully impregnated, and obtain a self-assembled iron-phytic acid-based complex through the complexation of metal and hydroxyl oxygen in phytic acid, and then place it in an oven at 80 °C dry.

[0032] (2) Carbonize the dried solid in a nitrogen atmosphere, raise the temperature to 800°C at a rate of 20°C / min, keep warm for 2 hours after carbonization, cool naturally, and wash repeatedly with acid and deionized water to remove metals in the product elements, and then dried at 80°C to obtain the porous graphitized carbon nanosheets.

[0033] The method of testing its degree of graphitization and specific surface area is the same as in Example 1.

[0034] The specific surface a...

Embodiment 3

[0036] (1) Weigh 2 g of phytic acid and dissolve it in 10 mL of deionized water, then add 10 mL of 0.20 g / mL potassium trioxalate ferrate solution dropwise into the phytic acid solution under stirring, and keep stirring for 1 hour , Add 0.15 g melamine sponge into the above mixed solution, stir to make it fully impregnated. The self-assembled iron-phytic acid complex was obtained by the complexation of the metal with the hydroxyl oxygen in phytic acid, and then dried in an oven at 80°C.

[0037] (2) Carbonize the dried solid in a nitrogen atmosphere, raise the temperature to 750°C at a rate of 5°C / min, keep it warm for 2 hours, cool naturally, and wash repeatedly with acid and deionized water to remove metals in the product elements, and then dried at 80°C to obtain the porous graphitized carbon nanosheets.

[0038] The method of testing its degree of graphitization and specific surface area is the same as in Example 1.

[0039] The specific surface area of the porous graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of graphitization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com