Collaborative graphitization method for amorphous carbon material

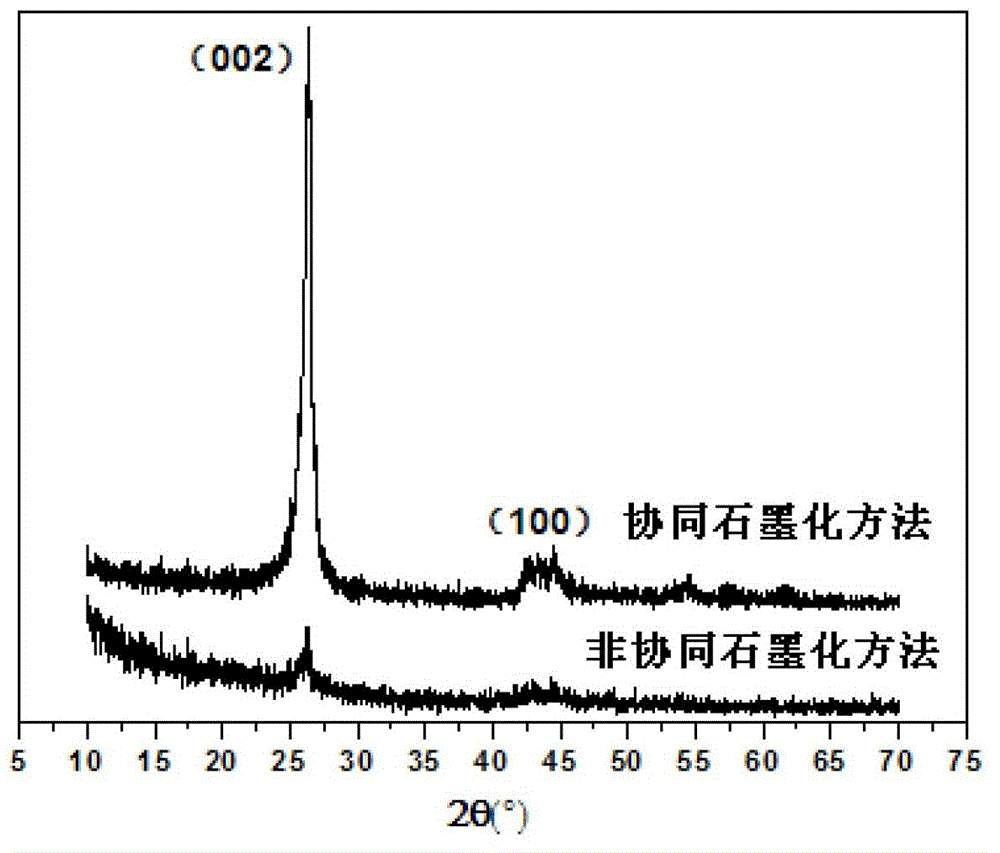

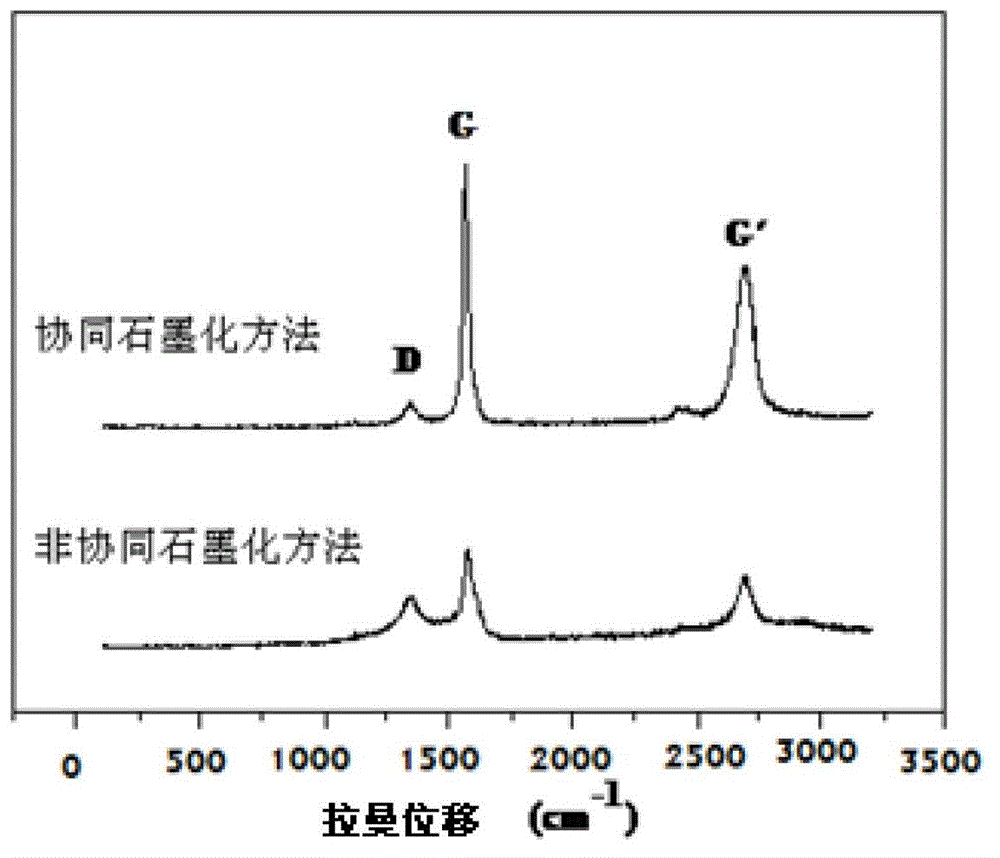

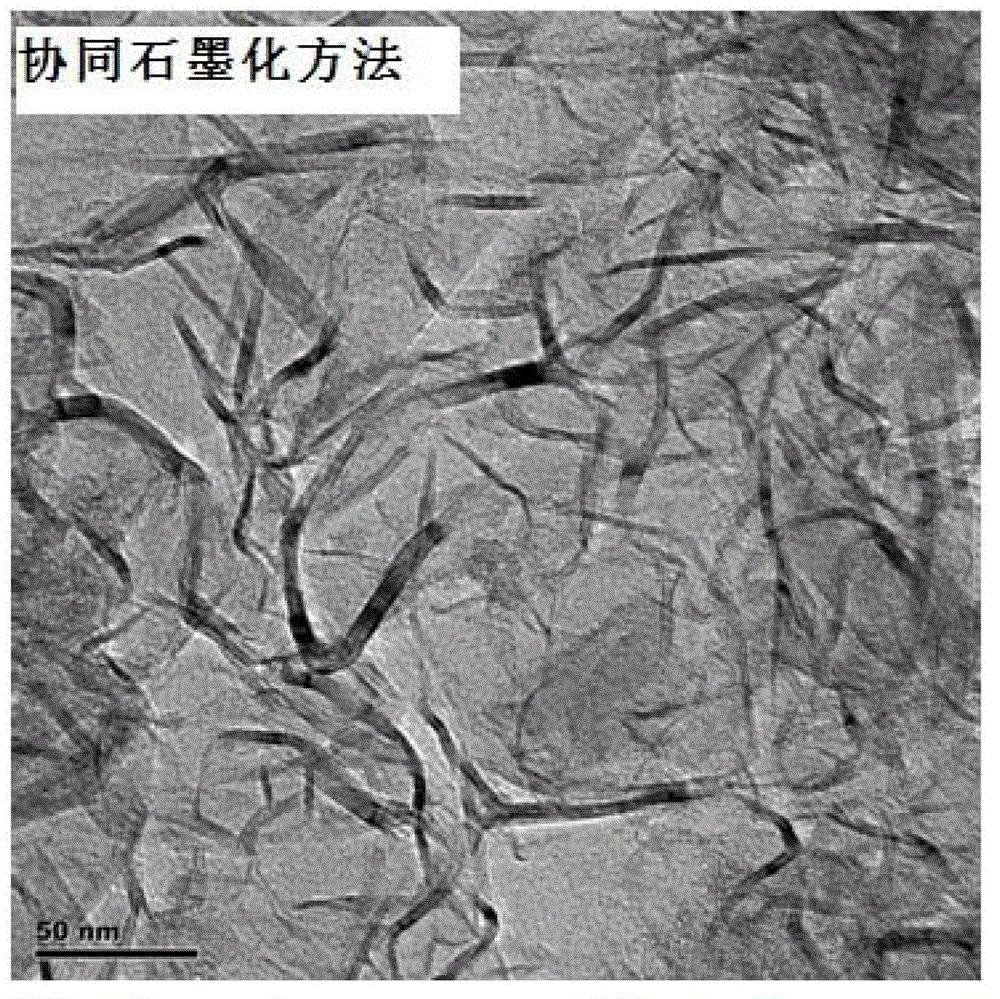

A technology of amorphous carbon and graphitization, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of low graphitization degree and poor uniformity of carbon materials, and achieve remarkable graphitization effect and process Simplicity and the effect of expanding the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of activated carbon material with ferric nitrate adsorbed

[0032] Weigh 300 mg of commercially available activated carbon, disperse it in 25 mL of ferric nitrate solution with a concentration of 0.5 mol / L at room temperature, stir for 2 hours, then let it stand for 24 hours, after filtering, put the filtered filter cake in an oven , and dried at 120°C for 24 hours to obtain an activated carbon material adsorbed with ferric nitrate.

[0033] (2) Graphitization of activated carbon material with adsorbed ferric nitrate

[0034] Weigh 200 mg of the activated carbon material with ferric nitrate adsorbed obtained in (1), weigh 500 mg of metallic sodium, put them in an alumina crucible with a cover and place the crucible in a tube furnace, blow in nitrogen, and heat at 5°C The temperature was raised to 800°C at a rate of 1 / min and kept at this temperature for 6h, and then lowered to room temperature to obtain a graphitized carbon material.

[0035] (3) Purif...

Embodiment 2

[0041] (1) Preparation of activated carbon material with ferric nitrate adsorbed

[0042] Weigh 400 mg of activated carbon, disperse it in 25 mL of ferric nitrate solution with a concentration of 1.0 mol / L at room temperature and stir for 2 h, then let it stand for 24 h, after filtering, place the sample in an oven and dry at 120 °C for 24 h, An activated carbon material having adsorbed ferric nitrate was obtained.

[0043] (2) Graphitization of activated carbon materials with adsorbed ferric nitrate

[0044] Weigh 200 mg of the activated carbon material with ferric nitrate adsorbed obtained in (1), weigh 500 mg of metallic sodium, put them in an alumina crucible with a cover and place the crucible in a tube furnace, blow in nitrogen, and heat at 5°C The temperature was raised to 800°C at a rate of 1 / min and kept at this temperature for 6h, and then lowered to room temperature to obtain a graphitized carbon material.

[0045] (3) Purification of graphitized carbon materials ...

Embodiment 3

[0049] (1) Preparation of activated carbon material with ferric nitrate adsorbed

[0050] Weigh 300 mg of activated carbon, disperse it in 25 mL of ferric nitrate solution with a concentration of 0.5 mol / L at room temperature and stir for 2 h, then let it stand for 24 h, after filtering, place the sample in an oven and dry at 120 °C for 24 h, An activated carbon material having adsorbed ferric nitrate was obtained.

[0051] (2) Graphitization of activated carbon material with adsorbed ferric nitrate

[0052] Weigh 200 mg of the activated carbon material with ferric nitrate adsorbed obtained in (1), weigh 500 mg of metallic sodium, put them in an alumina crucible with a cover and place the crucible in a tube furnace, blow in nitrogen, and heat at 10°C The temperature was raised to 600°C at a rate of 1 / min and kept at this temperature for 6h, and then lowered to room temperature to obtain a graphitized carbon material.

[0053] (3) Purification of graphitized carbon materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com