Preparation method of C/C (carbon/carbon) composite material slider for pantograph

A technology of composite materials and pantographs, which is applied in the field of material preparation for electric locomotives, can solve problems such as unstable performance, poor mechanical strength of pure carbon slides, and high resistivity, and achieve excellent mechanical properties, high material utilization, and reduced resistance rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

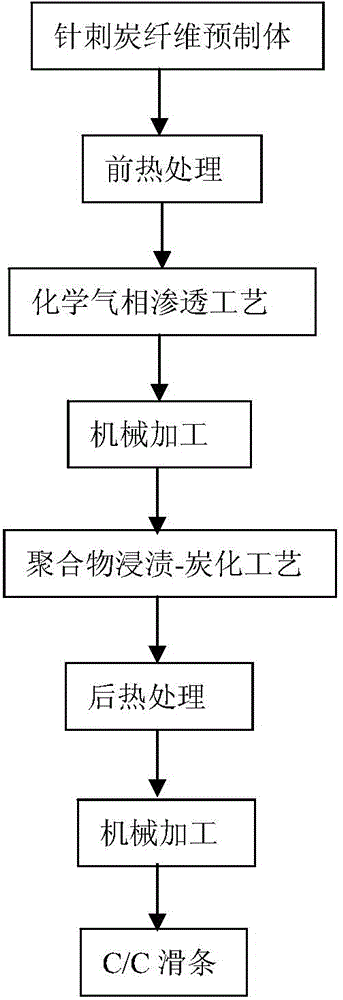

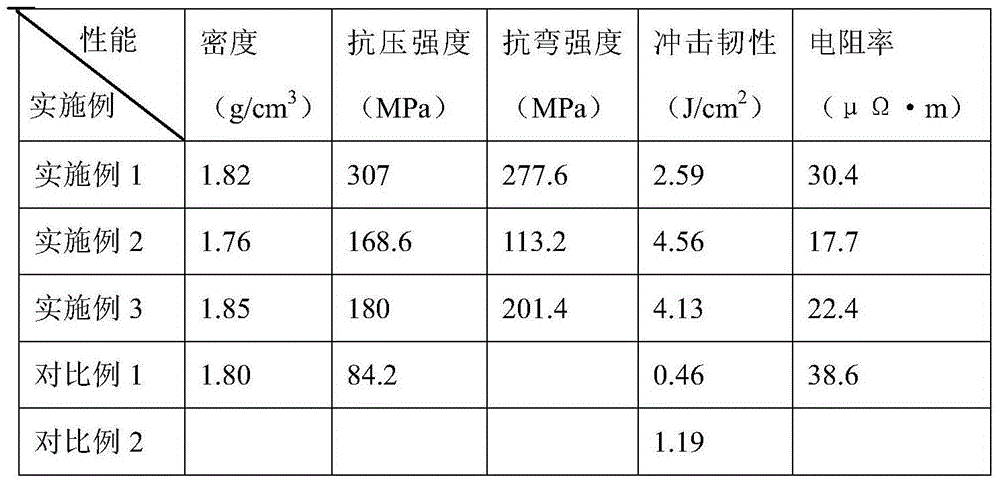

[0057] Using 2.5D carbon fiber needle-punched integral mat with a cloth-to-felt ratio of 8:2 as the prefabricated body, a density of 1.42 g / cm was prepared by chemical vapor infiltration. 3 The C / C porous body with a density of 1.82g / cm3 was prepared through three resin impregnation-carbonization processes. 3 The C / C composite material obtained by 2000°C high-temperature heat treatment and mechanical processing obtained the C / C slider.

[0058] The C / C pantograph carbon slider in this example is mainly prepared through the following steps:

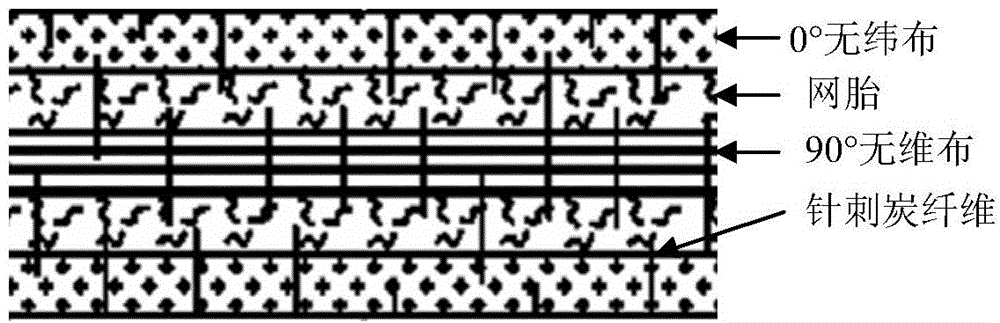

[0059] (1) First of all, the PAN type T700 (12K) carbon fiber produced by Japan's Toray Company (Toray) is used to make the mesh tire and the non-weft cloth, ensuring that the mass ratio of the non-weft cloth and the mesh tire is 8:2, and the single-layer 0° no-weft fabric, mesh layer, 90° no-weft fabric, and mesh layer are stacked in sequence, and then, the density is 0.56g / cm by the method of relay needle punching 3 Carbon fiber prefab...

Embodiment 2

[0067] Using 2.5D carbon fiber needle-punched integral mat with a cloth-to-felt ratio of 8:2 as the prefabricated body, a density of 1.51 g / cm was prepared by chemical vapor infiltration. 3 The C / C composite material with a density of 1.76g / cm was prepared through two resin impregnation-carbonization processes. 3 The C / C composite material obtained by 2300 ℃ high temperature heat treatment and machining to obtain the C / C slider.

[0068] The C / C pantograph slider in this example is mainly prepared through the following steps:

[0069] (1) First of all, the PAN type T700 (12K) carbon fiber produced by Japan's Toray Company (Toray) is used to make the mesh tire and the non-weft cloth, ensuring that the mass ratio of the non-weft cloth and the mesh tire is 8:2, and the single-layer 0° no-weft cloth, mesh layer, 90° no-weft cloth, and mesh layer are stacked in sequence, and then, the density is 0.35g / cm by the method of relay needle punching 3 carbon fiber prefabricated body, 10...

Embodiment 3

[0077] Using 2.5D carbon fiber needle-punched integral mat with a cloth-to-felt ratio of 8:2 as the prefabricated body, a density of 1.65 g / cm was prepared by chemical vapor infiltration. 3 The C / C composite material with a density of 1.85g / cm was prepared after two asphalt impregnation-carbonization processes 3 The C / C composite material obtained by 2300 ℃ high temperature heat treatment and machining to obtain the C / C slider.

[0078] The C / C pantograph slider in this example is mainly prepared through the following steps:

[0079] (1) First of all, the PAN type T700 (12K) carbon fiber produced by Japan's Toray Company (Toray) is used to make the mesh tire and the non-weft cloth, ensuring that the mass ratio of the non-weft cloth and the mesh tire is 8:2, and the single-layer 0° no-weft fabric, mesh layer, 90° no-weft fabric, and mesh layer are stacked in sequence, and then, the density is 0.56g / cm by the method of relay needle punching 3 The carbon fiber prefabricated bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com