Synthetic graphite negative electrode material for lithium ion battery and preparation method as well as application thereof

A technology for artificial graphite negative electrodes and lithium-ion batteries, which can be used in battery electrodes, secondary batteries, chemical instruments and methods, etc., and can solve problems such as low compaction density, low specific capacity of artificial graphite, and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

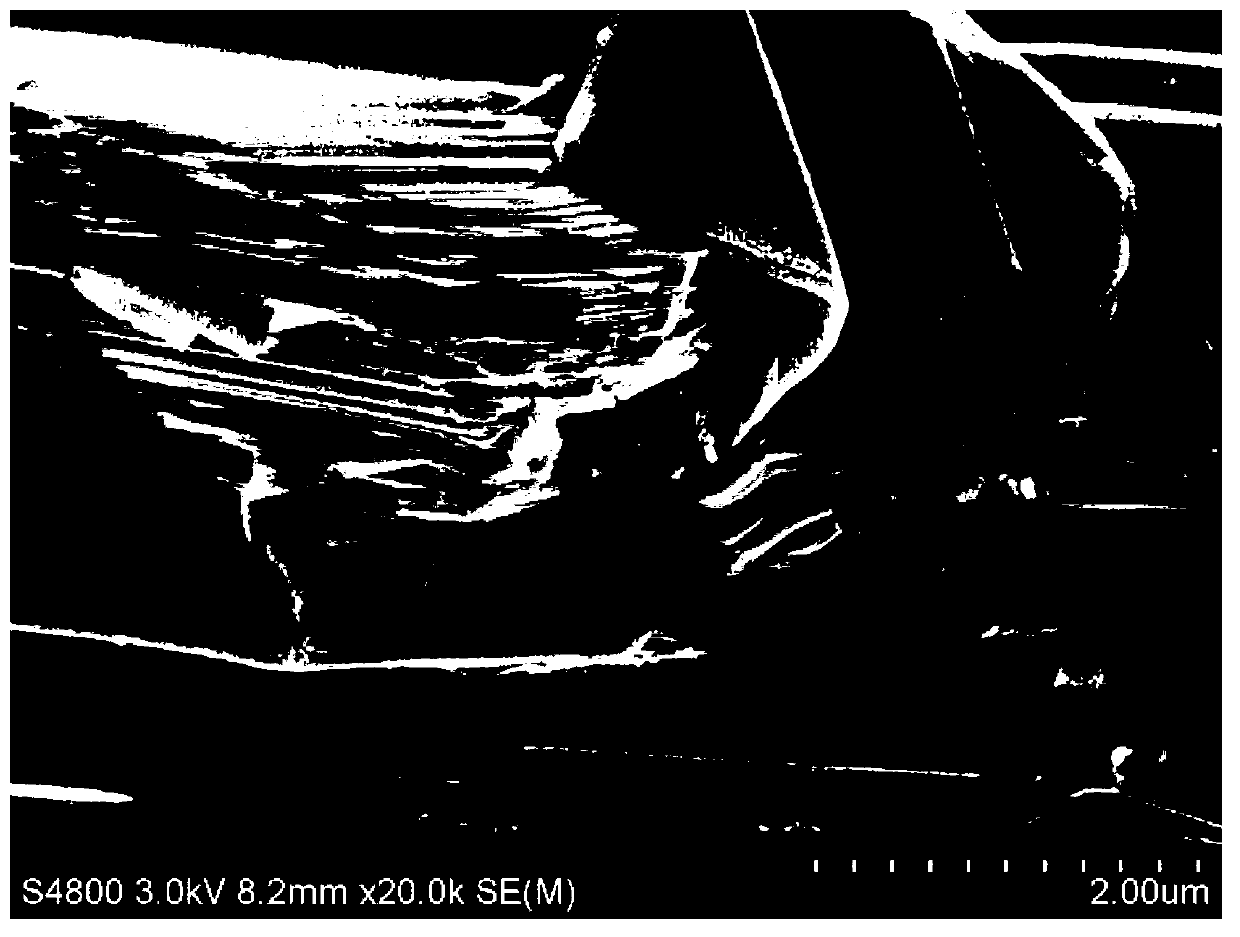

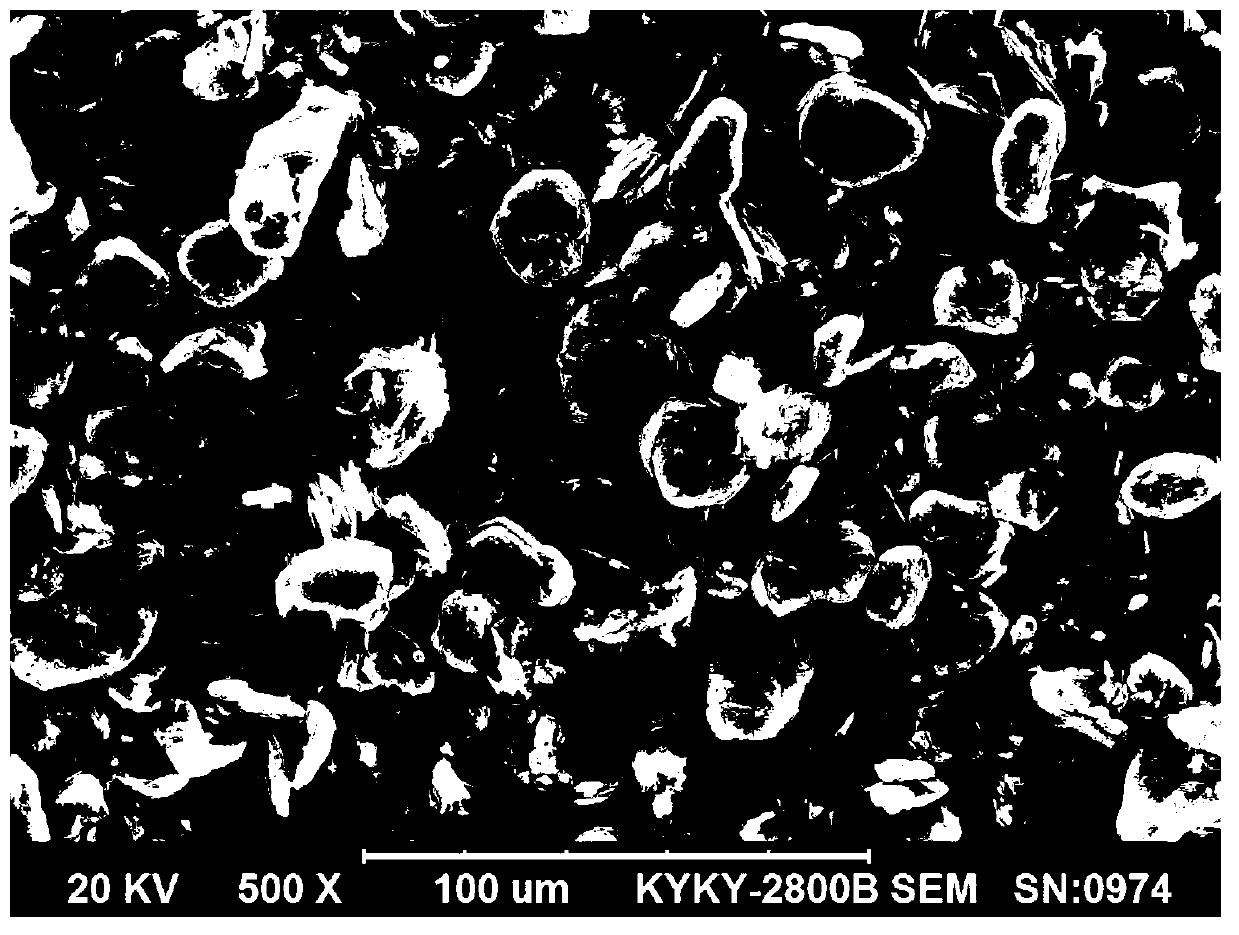

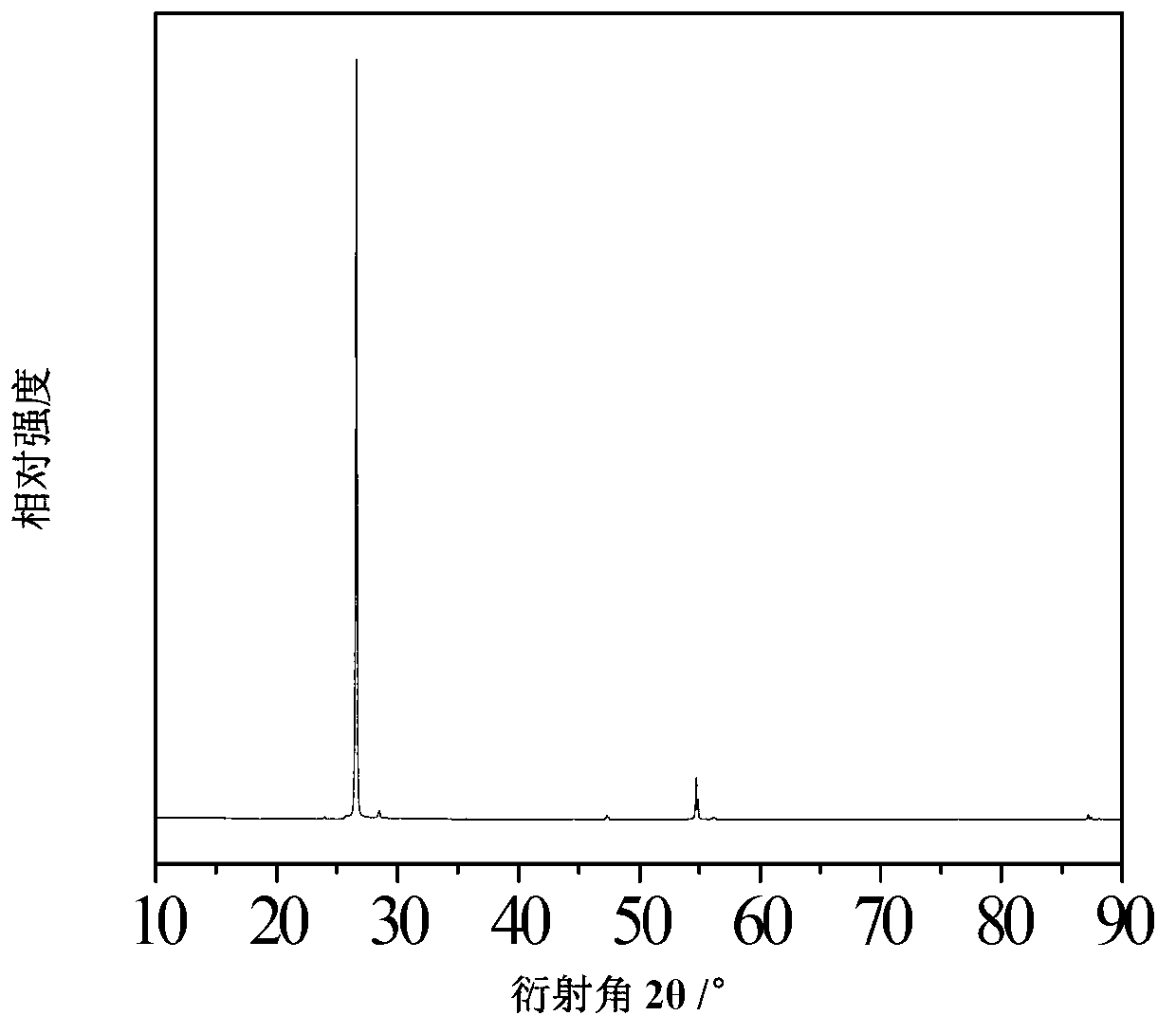

[0070] The preparation method of lithium ion battery artificial graphite negative electrode material of the present invention comprises the following steps:

[0071] (1) The purity is 98.2%~99.2%, the average particle size is 6.6~60μm, and the specific surface area is 0.56~3.43m 2 A mixture of one or more non-metallic carbides / g is added to the inner series graphitization furnace, and the temperature rise rate is 1~20℃ / min, and the temperature range is 2400~3000℃ for 4~8h. The above reaction atmosphere is a vacuum atmosphere, or an atmosphere filled with protective gas and / or reducing gas; the gas flow rate is 0-150L / h, and then naturally cooled to room temperature to obtain the final product or use it as an intermediate product 1. The gas flow rate is the flow rate of the protective gas and / or reducing gas introduced in the reaction vessel. When the gas flow rate is 0L / h, the corresponding reaction atmosphere is a vacuum atmosphere, that is, it is not necessary to pass gas in...

specific Embodiment

[0115] The technology and parameter thereof of embodiment 1~6 and comparative example 1 are shown in table 2.

[0116] Among them, comparative example 1 only carried out graphitization treatment once without subsequent process on the basis of the preparation method of the present invention; comparative example 2 and comparative example 3 are the presentation of the general artificial graphite preparation method, and comparative example 2 is described in CN200610014878.6 The artificial graphite prepared by the artificial graphite preparation method; Comparative Example 3 is the artificial graphite prepared by the artificial graphite preparation method described in CN200410018079.7.

[0117] The process condition of table 2 embodiment 1-6 and comparative example 1

[0118]

[0119]

[0120] The test results of physical and electrical properties of the artificial graphite prepared in Examples 1-6 and Comparative Examples 1-3 are shown in Table 3.

[0121] The physical perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com