Preparation method for carbon dry gel

A xerogel, gel technology, applied in chemical instruments and methods, catalyst activation/preparation, electrical components, etc., can solve problems such as pore structure, specific surface area and other properties that need to be further optimized, to speed up the commercialization process, solvent Safe, high oxygen reduction reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

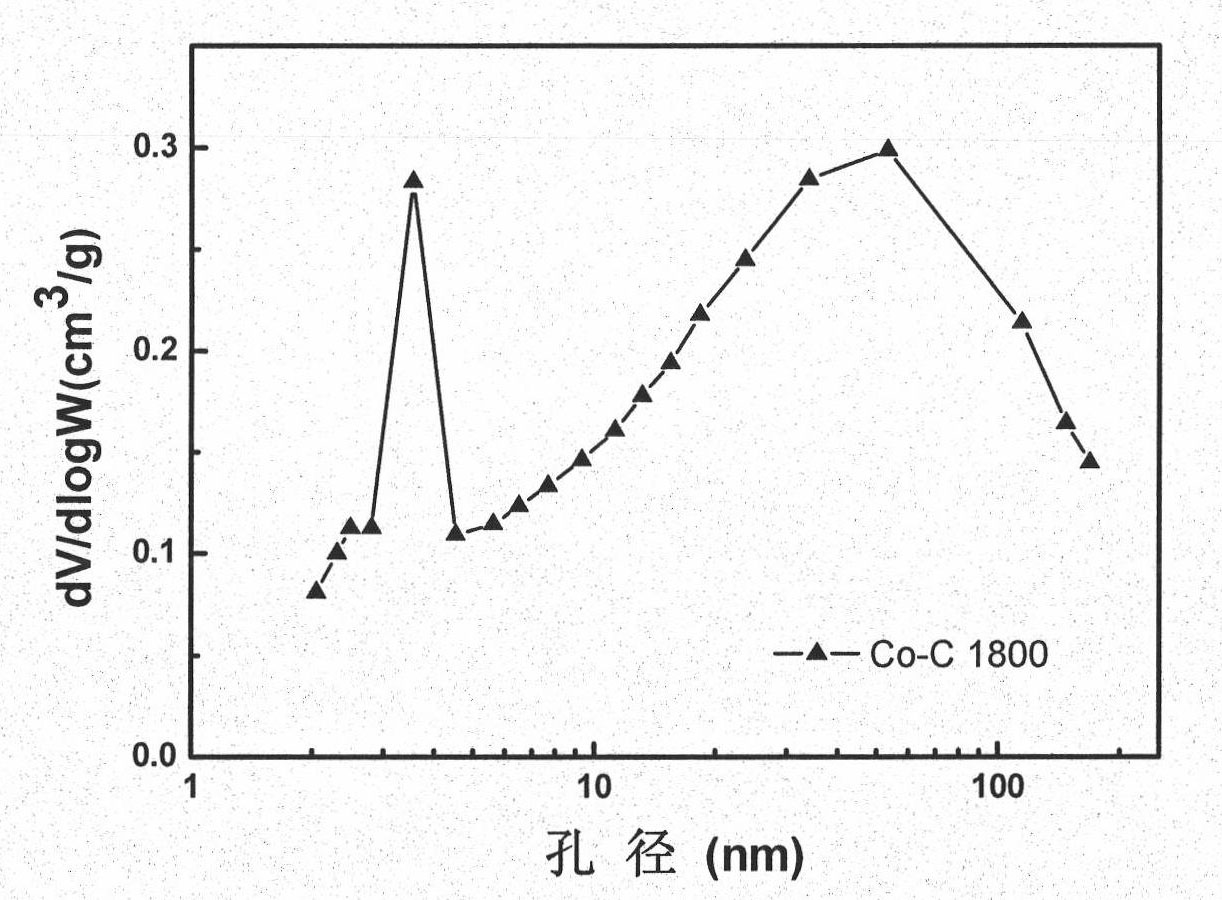

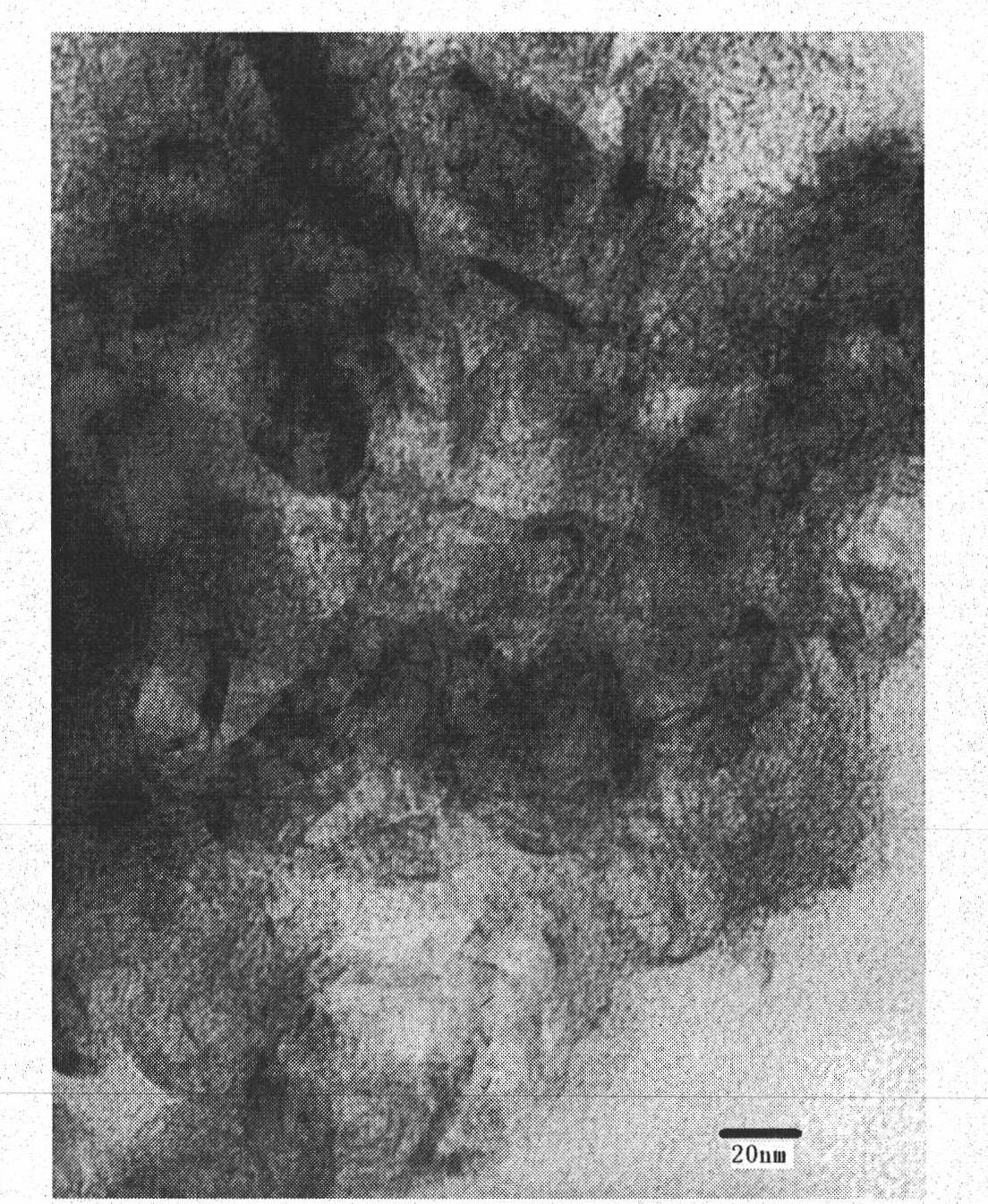

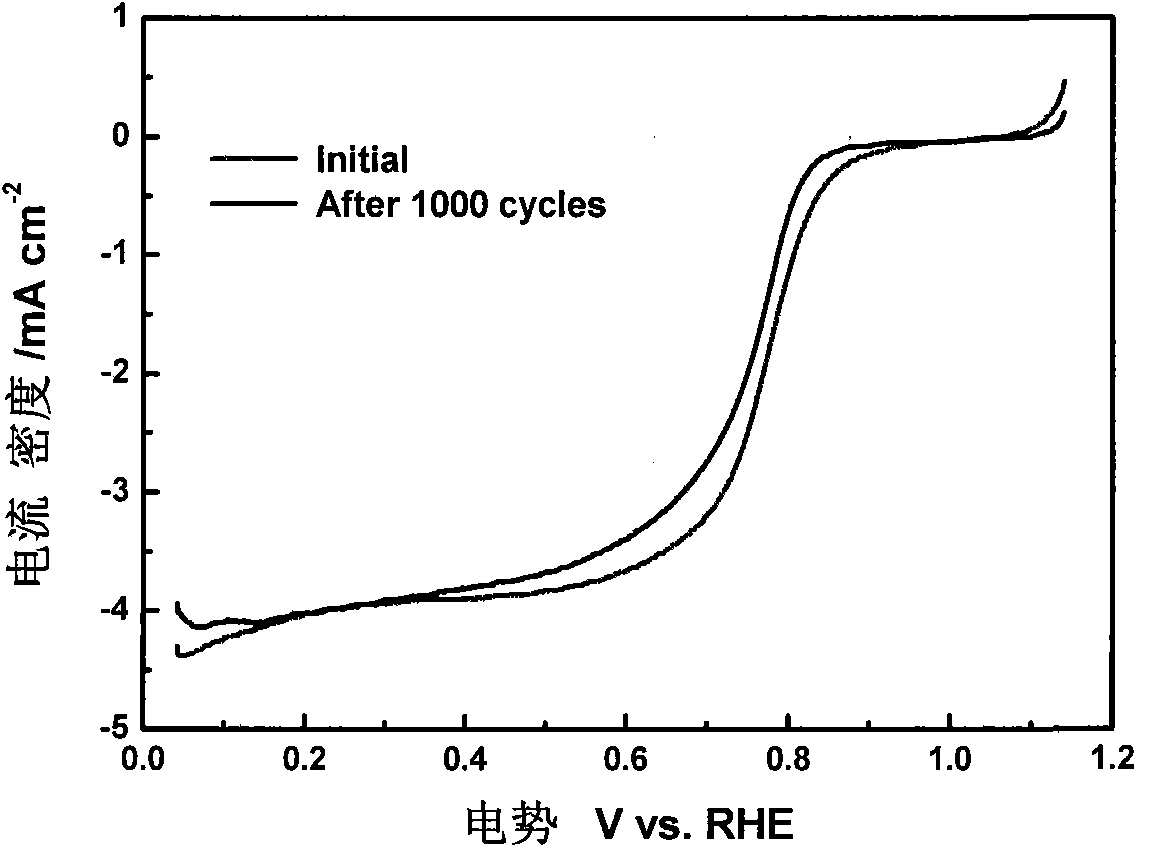

[0041] Dissolve 6.16g of resorcinol in 4mL of deionized water to form a transparent solution A; take 5.13ml of cobalt nitrate hexahydrate aqueous solution with a concentration of 20mg / mL and add it dropwise to the above-mentioned transparent solution A while stirring, and mix well to obtain solution B ; Add 9.08g of formaldehyde solution dropwise to the stirring solution B, further stir and mix evenly, and continue to stir in an environment of 60°C until the reaction forms gel C; transfer the gel C to a vacuum drying oven for vacuum drying at 80°C Aging treatment for 7d, crushing and grinding after taking out to obtain solid powder D; solid powder D was graphitized at 1800°C in N2 for 3h, N 2 Gas purged to room temperature, 0.5M H 2 SO 4 The solution was washed to remove metal salts to obtain a carbon xerogel carrier Co-CX with a molar ratio of resorcinol and cobalt nitrate of 32:1. The Pt / Co-CX1800 catalyst with a mass fraction of 20% was prepared by ethylene glycol reducti...

Embodiment 2

[0048] Dissolve 6.16g of resorcinol in 7mL of deionized water to form a transparent solution A; take 0.4355g of cobalt acetate tetrahydrate solid and add it to the above transparent solution A while stirring, and mix well to obtain solution B; Add 9.08g of formaldehyde solution dropwise, stir and mix evenly, and keep stirring at 20°C until the reaction forms gel C; transfer the gel C to a vacuum drying oven for 3 days of vacuum drying and aging treatment at 60°C, take it out, crush and grind , to obtain solid powder D; solid powder D in N 2 Medium 1500℃ high temperature graphitization treatment for 1h, N 2 Gas purged to room temperature, 2M HNO 3 The solution was washed to remove metal salts to obtain a carbon xerogel carrier Co-CX1500 with a molar ratio of resorcinol and cobalt acetate of 32:1. The Pt / Co-CX1500 catalyst with a mass fraction of 20% was prepared by ethylene glycol reduction method. The electrochemical and battery accelerated decay test results show that befo...

Embodiment 3

[0050] Dissolve 6.16g of resorcinol in 2mL of deionized water to form a transparent solution A; take 0.7063g of ferric nitrate nonahydrate solid and add it to the above transparent solution A while stirring, mix and dissolve evenly to obtain solution B; Add 9.08g of formaldehyde solution dropwise, stir and mix evenly, and continue to stir at 90°C until the reaction forms gel C; transfer gel C to a vacuum drying oven for 3 days of vacuum drying and aging treatment at 80°C, take it out and pulverize Grinding to obtain solid powder D; the solid powder D was graphitized in Ar at 1900°C for 5 h, purged with Ar gas to room temperature, and 4M HNO 3 The solution was washed to remove metal salts to obtain a carbon xerogel carrier Fe-CX1900 with a molar ratio of resorcinol and iron nitrate of 32:1. The Pt / Fe-CX1900 catalyst with a mass fraction of 20% was prepared by sodium borohydride reduction method. The electrochemical and battery accelerated decay test results show that before an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com