Method for preventing ethylene cracking furnace from coking

A technology of ethylene cracking furnace and cracking furnace, which is applied in the direction of hydrocarbon cracking, hydrocarbon production, organic chemistry, etc. It can solve problems such as coking, coking when the furnace is shut down, and affecting the operation cycle of the cracking furnace, so as to change the coke structure, suppress coking, and suppress non- Homogeneous catalytic coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

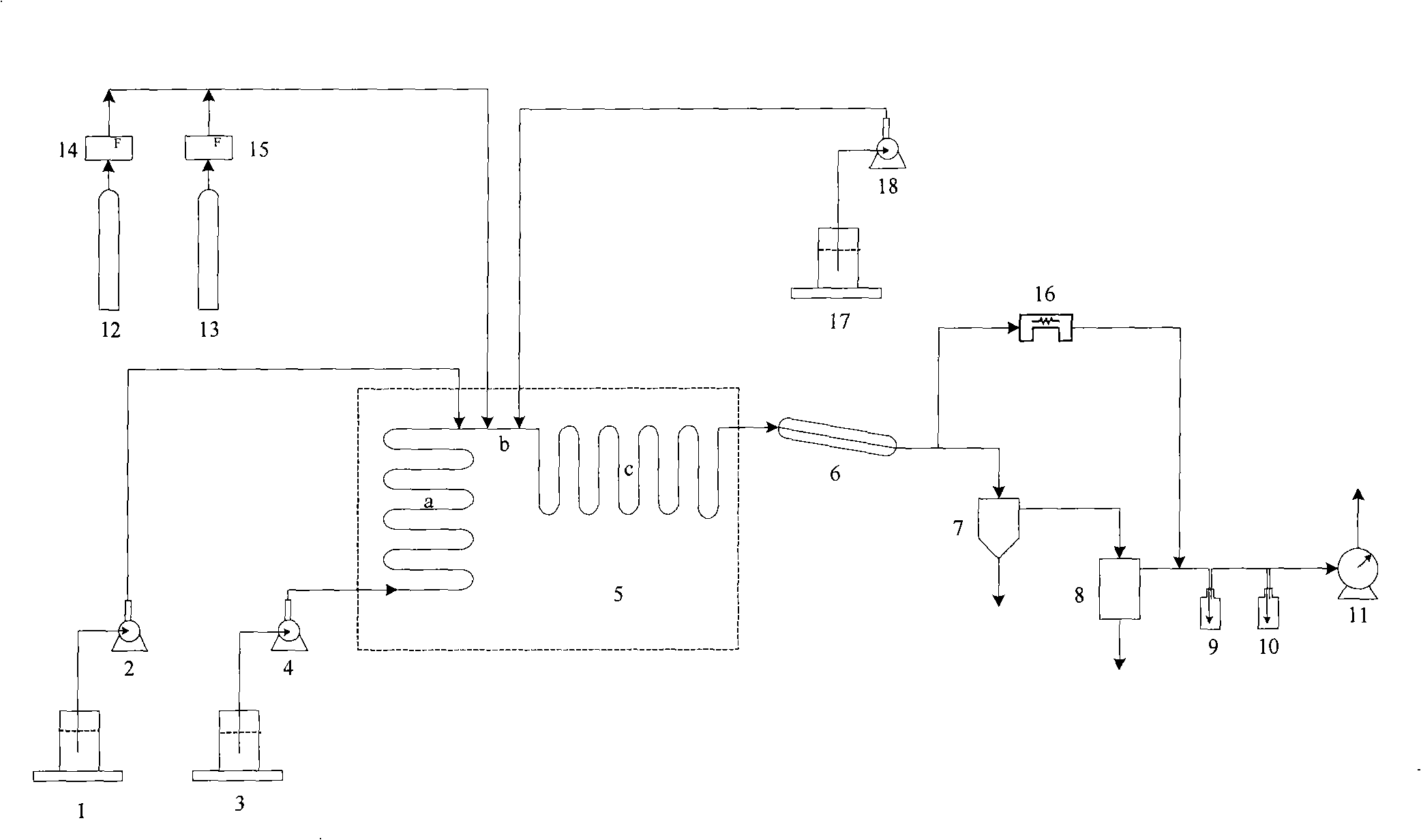

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 and embodiment 2 are the result that industrial cracking furnace is processed.

[0034] Example 1

[0035] The device is a 60,000 tons / year ethylene SRT-IV (HC) industrial cracking furnace, which is divided into six groups of feed materials, and three waste heat boilers are connected in parallel. In the furnace tube of the cracking furnace radiant section, twisted tubes are arranged in the form of mutual intervals. , the twisted sheet twists 180°, and the distance between two adjacent twisted sheet tubes is 15 pitches; during the operation of the cracking furnace (the cracking raw material is heavy diesel oil), the heavy diesel oil feed rate is 26t / h, and the diluted The steam feed rate is 19.5t / h, and under the companionship of the carrier gas steam (9kg / h), n-butanethiol is continuously injected into the cracking furnace along with the cracking raw materials, and the injection rate is 1.5kg / h. The weight ratio of n-butanethiol to raw material is about 58...

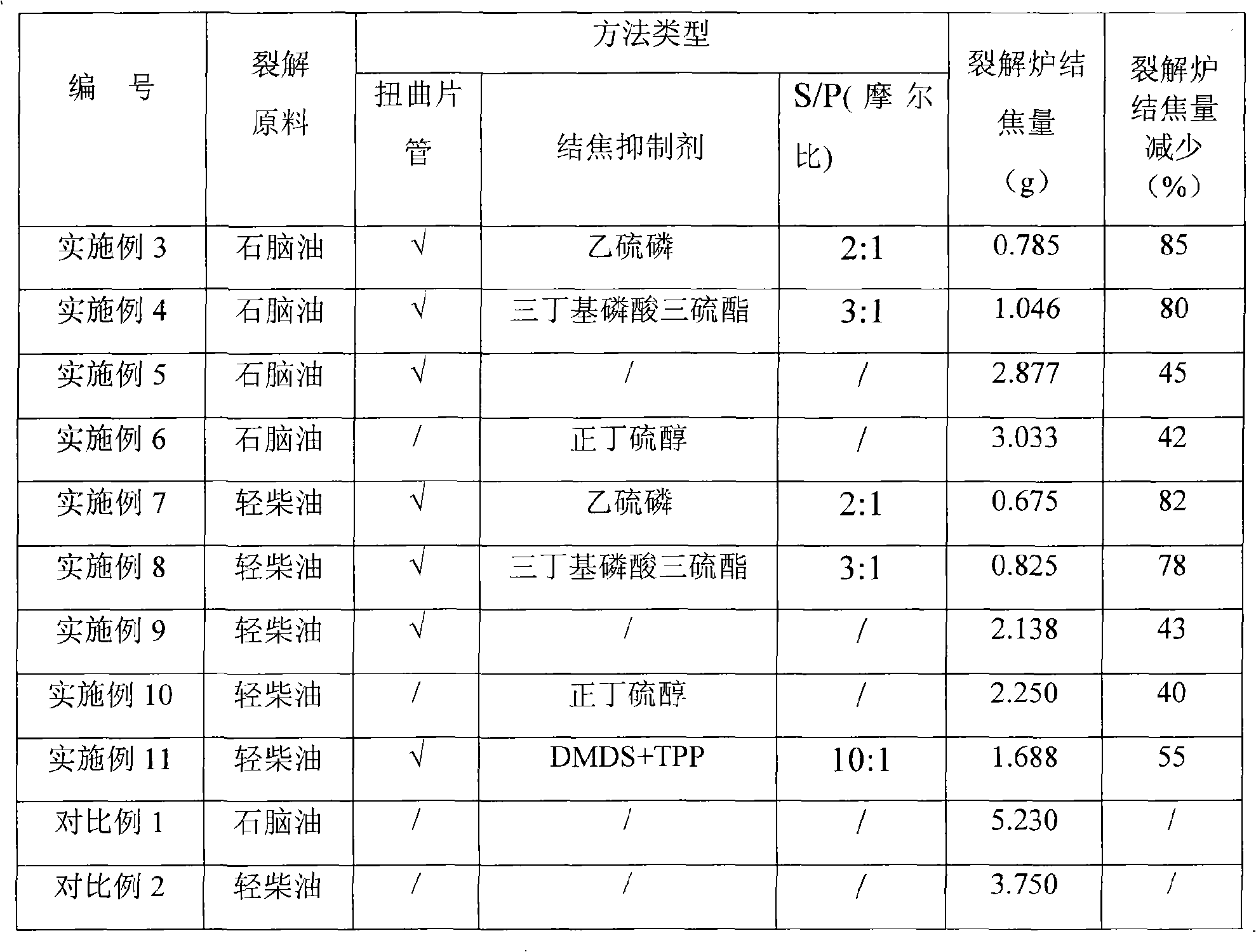

Embodiment 2

[0037] The device is a 30,000-ton / year ethylene GK-V cracking furnace, which is divided into four groups of feed materials. There are two waste heat boilers. In the furnace tube of the radiant section of the cracking furnace, twisted sheet tubes are arranged in the form of mutual intervals, and the twisted sheets are twisted. 180°, and the distance between two adjacent twisted sheets is 20 pitches; during the hot standby period before the cracking furnace is put into oil operation, the outlet temperature of the cracking furnace is 700-850°C, and the sulfur-phosphorus compound tributyl phosphate tri Thioester (wherein the atomic molar ratio of elemental sulfur and elemental phosphorus is S: P=3: 1), accompanied by carrier gas water vapor (6kg / h), is injected into the cracking furnace from the spanning section of the cracking furnace. The amount is 2.8kg / h, and the injection time is 5 hours; then steam cracking is carried out, and the cracking raw material is naphtha, and the nap...

Embodiment 3

[0043] Simulate the SRT-III type cracking furnace, adopt the method of the present invention, add 3 sections of twisted sheet tubes in the furnace tube of the radiant section, when the cracking furnace outlet temperature is 800 ° C, the mass concentration is 0.3% ethion-naphtha The oil injection agent is injected into the cracking furnace from the spanning section of the cracking furnace for pretreatment, wherein the atomic molar ratio of sulfur and phosphorus is S:P=2:1, the injection rate is 200g / h, and the treatment time is 30 minutes; then When naphtha cracking was carried out at the outlet temperature of the cracking furnace at 840°C, the ethion-naphtha injection was continued to be injected from the spanning section of the cracking furnace until the end of the test, and the injection rate was 16g / h. The physical properties of raw naphtha are: distillation range 48-211°C, specific gravity D 15.6 0.7287g / ml, sulfur content 165PPM; cracking conditions: cracking temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com