Piston for internal combustion engine

A technology for internal combustion engines and pistons, applied in the field of improving the cooling performance of pistons, to achieve low cost, simple structure, and the effect of suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

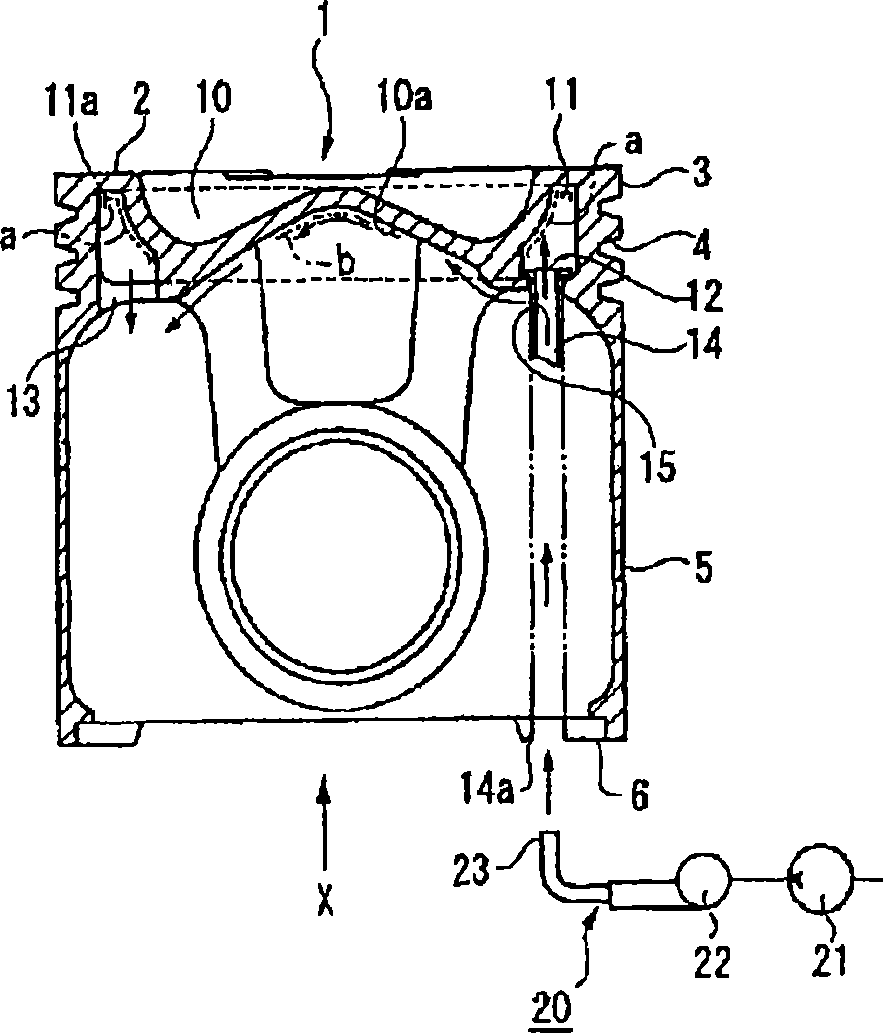

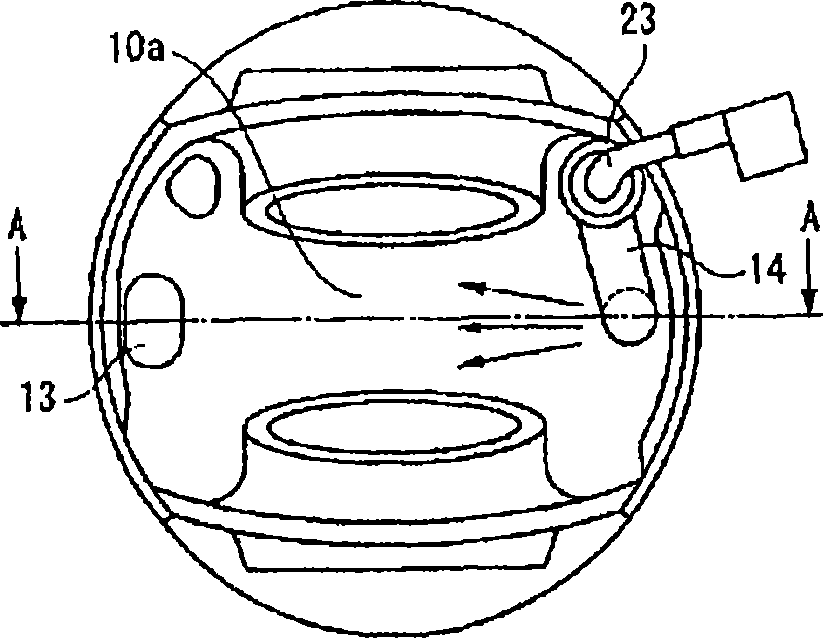

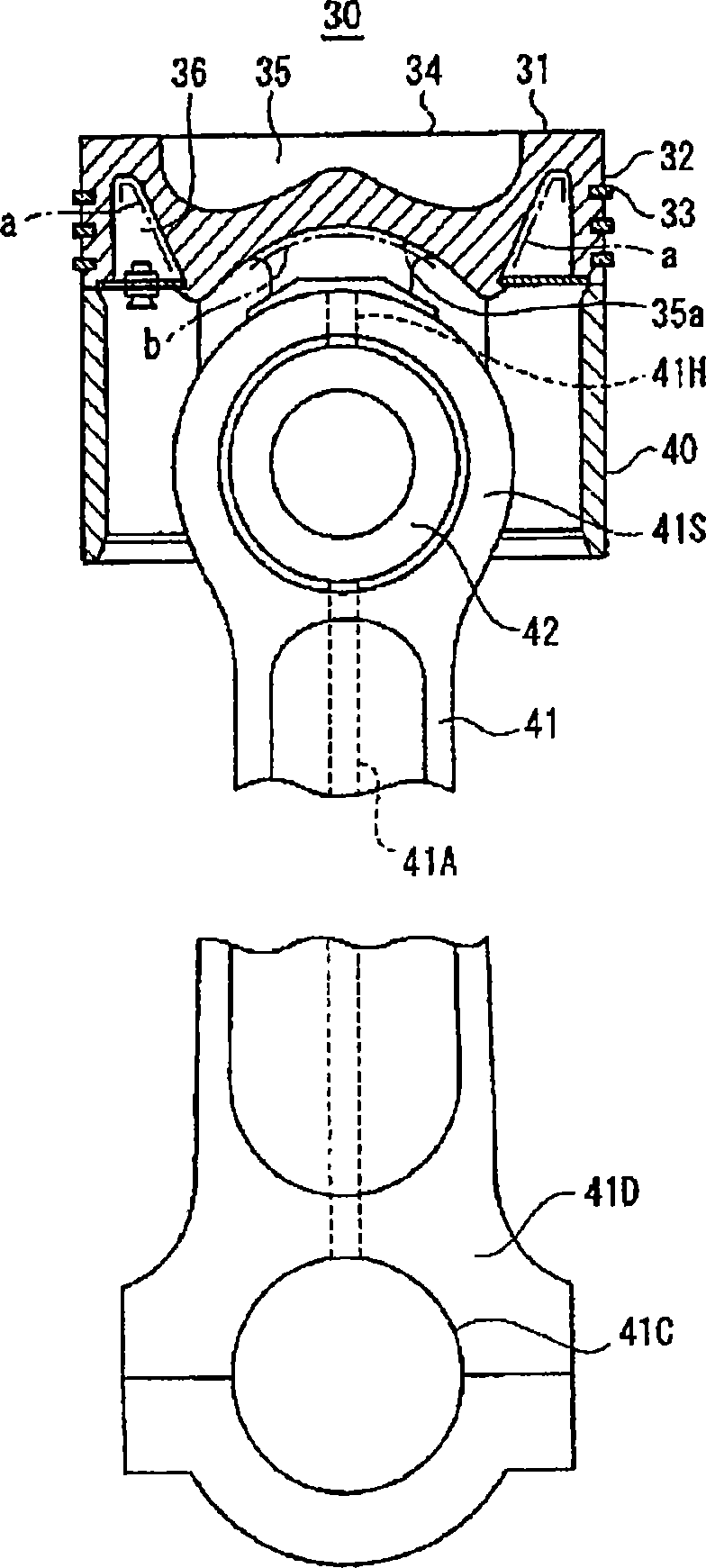

[0046] Figure 4 It is a side cross-sectional view showing the casting integral type piston head of the first embodiment of the present invention, Figure 5 It is a side cross-sectional view showing a hinged type piston head.

[0047] In this example, in Figure 4 Among them, the surface roughness of the back surface 10a of the combustion chamber 10 of the piston 1 and the inner wall 11a of the cooling cavity 11 is 6.3S. In addition, in Figure 5 Among them, the surface roughness of the back surface 35a of the combustion chamber 35 of the articulated piston 30 and the inner wall 36a of the cooling groove 36 is less than or equal to 6.3S. Specifically, in Figure 4 , Figure 5 The surface roughness of at least the two-dashed line parts a' and b' shown above is less than or equal to 6.3S. Double dotted line part a', b' part and figure 1 , image 3 The two-dot dash line part a, b part corresponds to.

[0048] However, it is also conceivable to make only the surface rough...

no. 2 example

[0052] In the second embodiment of the present invention, same as the first embodiment, on the piston 1, the surface roughness of the back surface 10a of the combustion chamber 10 and / or the inner wall 11a of the cooling cavity 11 is less than or equal to 6.3S, in On the piston 30, the surface roughness of the back surface 35a of the combustion chamber 35 and / or the inner wall 36a of the cooling groove 36 is less than or equal to 6.3S, and further, the surface roughness of the surface is less than or equal to 6.3S. coating.

[0053] The surface coating of this example is Figure 6 The self-purifying catalyst film 50 is shown.

[0054] The self-purifying catalyst film 50 is composed of a catalyst, a heat-resistant bonding material (glass frit), and a porous texture (matte) forming material, which has the function of oxidizing and burning the attached oil into water vapor and carbon dioxide in a non-flame state by catalytic action. function. In addition, when the engine is op...

no. 3 example

[0061] In the third embodiment of the present invention, as Figure 7 As shown, as the surface coating, instead of the self-purifying catalyst film 50 of the second embodiment, a catalyst-free enamel coating film 60 is used. The film 60 is formed from a single layer of catalyst-free enamel parts. The composition of the enamel may be the same as that of the heat-resistant bonding material of the second embodiment, and a composition generally used for low-temperature enamel-type enamel coating may be applied. The thickness of the film 60 should be determined in consideration of the influence on the cooling effect, which is about 2-1000 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com