Inhibition to oxidation coking of aviation kerosene by acid cleaning and passivation

A technology of aviation kerosene and coking, which is applied in the direction of damage protection, pipeline protection, pipeline anticorrosion/rust protection, etc. It can solve the problems of hidden dangers of engines, easy breakage, and affecting heat exchange efficiency, etc., and achieves inhibition of coking, not easy to fall off, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

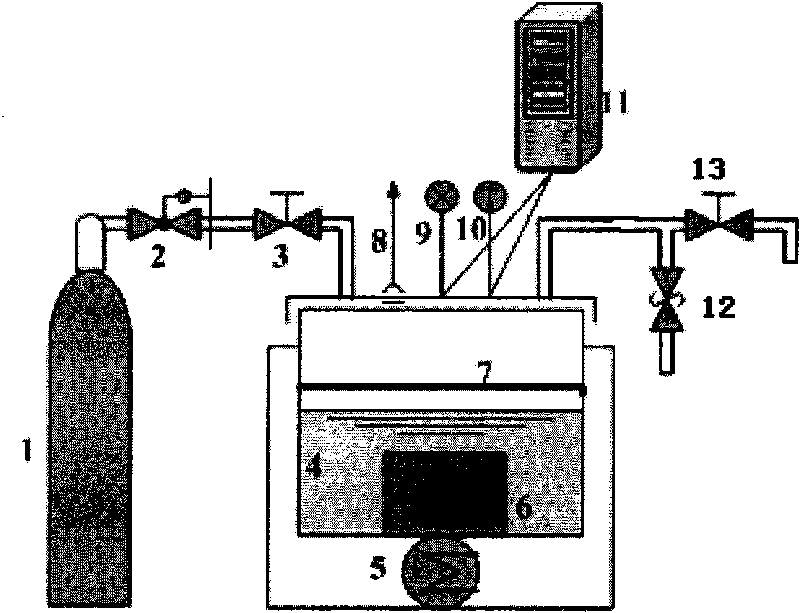

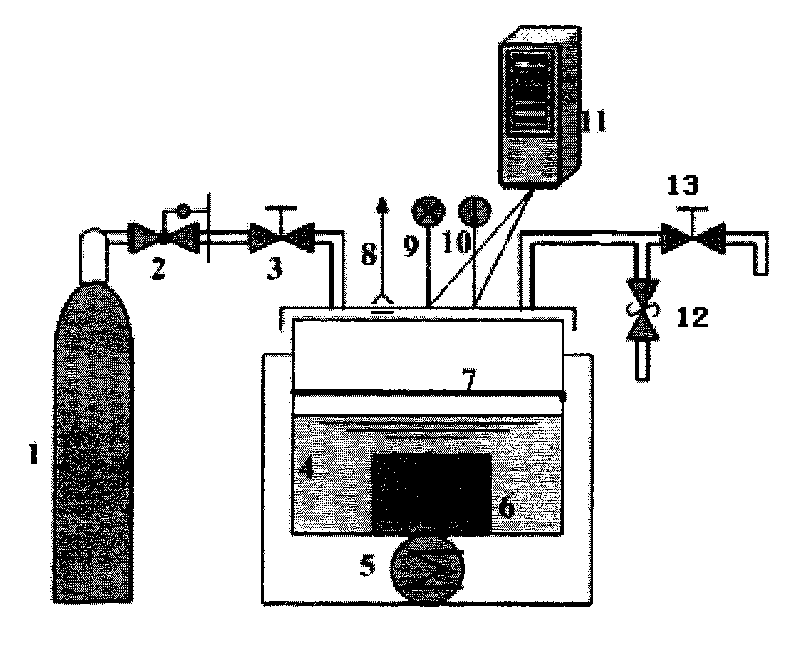

[0013] This scheme is to change the metal activity of the metal surface by pre-treating the metal surface, so as to achieve the purpose of inhibiting the oxidation and coking of kerosene. Water washing-passivation-water washing-neutralization-water washing-drying-dehydrogenation. The key steps are described below:

[0014] 1. Degreasing. Degreasing consists of two steps: preliminary degreasing and chemical degreasing. First use gasoline for preliminary oil removal, slowly pass the gasoline through the metal pipe (0.3g / s) to fully dissolve the dirty oil in the pipe wall, and increase the gasoline flow rate (2-4g / s) after passing the oil for 15 minutes, so that It washes away oil stains. Before chemical degreasing, put the metal into the air circulation furnace to fully volatilize the gasoline in the tube. Chemical degreasing uses sodium oxide 60-80g / L, sodium phosphate 20-40g / L, sodium carbonate 20-40g / L, sodium silicate 3-10g / L. The total alkalinity is 65-100g / L, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com