Carrier, residual oil hydrogenation catalyst based on carrier, and preparation method of carrier

A residue hydrogenation and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low metal removal rate and desulfurization activity, heavy oil or residue The problems of low oil conversion rate and low catalytic activity can improve the metal removal rate and desulfurization activity, improve the catalytic activity, and facilitate the diffusion and mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

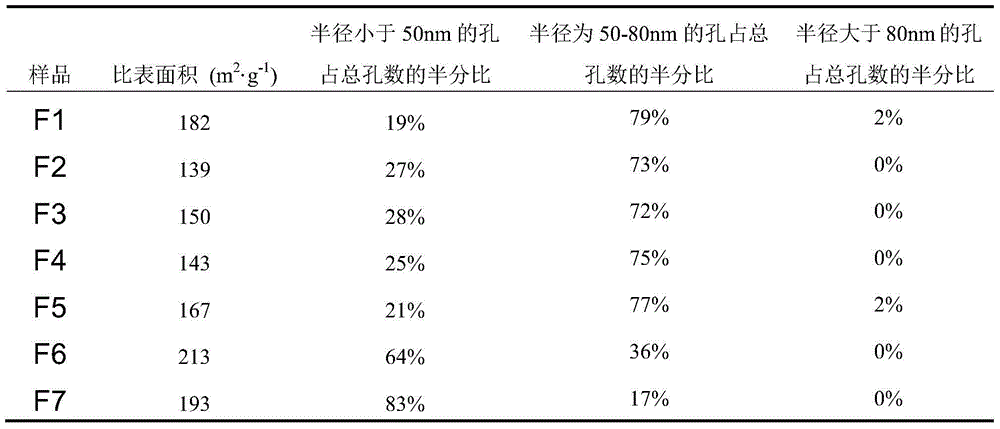

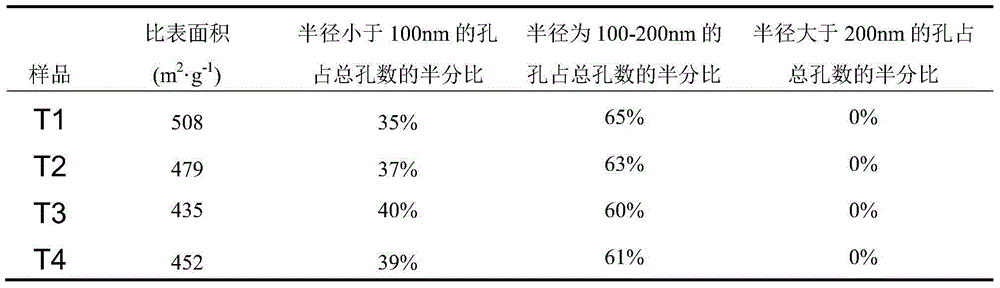

Examples

Embodiment 1

[0033] This embodiment provides a residual oil hydrogenation catalyst, and the raw materials used to prepare the residual oil hydrogenation catalyst include:

[0034] Modified kaolin carrier, 70 parts by weight;

[0035] Active metal Mo, 3 parts by weight (with Mo 2 o 3 count);

[0036] Activated carbon, 19 parts by weight, the specific surface area of the activated carbon is 500m 2 / g, on the activated carbon, the pores with a radius of 80-120nm account for 55% of the total number of pores;

[0037] Wherein, the carrier is prepared by the following method:

[0038] (1) Weigh the original kaolin soil and the pore-enlarging agent sodium carbonate respectively and mix them uniformly, control the mass ratio of the original kaolin soil and the pore-enlarging agent to 1:6, and carry out in nitrogen at a temperature of 600°C. Reaming treatment 3h;

[0039] (2) The product of step (1) is pickled twice with hydrochloric acid with a mass fraction of 15%, and washed with water o...

Embodiment 2

[0044] This embodiment provides a residual oil hydrogenation catalyst, and the raw materials used to prepare the residual oil hydrogenation catalyst include:

[0045] Modified kaolin carrier, 55 parts by weight;

[0046] Active metal W, 9 parts by weight (in WO 3 count);

[0047] Coal activated carbon after activation treatment, 40 parts by weight;

[0048] Rare earth metal La, 2 parts by weight (as La 2 o 3 count);

[0049] Wherein, the carrier is prepared by the following method:

[0050] (1) Take kaolin raw soil and pore-enlarging agent potassium carbonate respectively and mix uniformly, control the mass ratio of described kaolin raw soil and described pore-enlarging agent to be 1:4, in the mixed gas atmosphere of nitrogen and carbon dioxide, 500 Under the temperature condition of ℃, carry out the hole expansion treatment for 8h;

[0051] (2) The product of step (1) is pickled once with hydrochloric acid with a mass fraction of 20%, and then washed with water once af...

Embodiment 3

[0059] This embodiment provides a residual oil hydrogenation catalyst, and the raw materials used to prepare the residual oil hydrogenation catalyst include:

[0060] Modified kaolin carrier, 80 parts by weight;

[0061] Active metal Mo (with Mo 2 o 3 meter), 4 parts by weight;

[0062] Blue charcoal gac after activation treatment, 15 parts by weight;

[0063] Rare earth metal Pr (in Pr 2 o 3 meter), 6 parts by weight.

[0064] Wherein, the carrier is prepared by the following method:

[0065] (1) Take kaolin raw soil and pore-enlarging agent sodium carbonate respectively and mix uniformly, control the mass ratio of described kaolin raw soil and described pore-enlarging agent to be 1:8, in the mixed gas atmosphere of oxygen and carbon dioxide, 800 Under the temperature condition of ℃, carry out hole expansion treatment for 1h;

[0066] (2) The product of step (1) is pickled once with hydrochloric acid with a mass fraction of 25%, and then washed with water once after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com