Technique for producing ethyl benzene

A technology of ethylbenzene and ethanol, which is applied in the field of production of ethylbenzene, can solve the problems of inconvenient storage and transportation, high prices of ethylene and petroleum benzene, rising price of styrene, etc., and achieve the purpose of inhibiting catalyst coking and long service life , the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

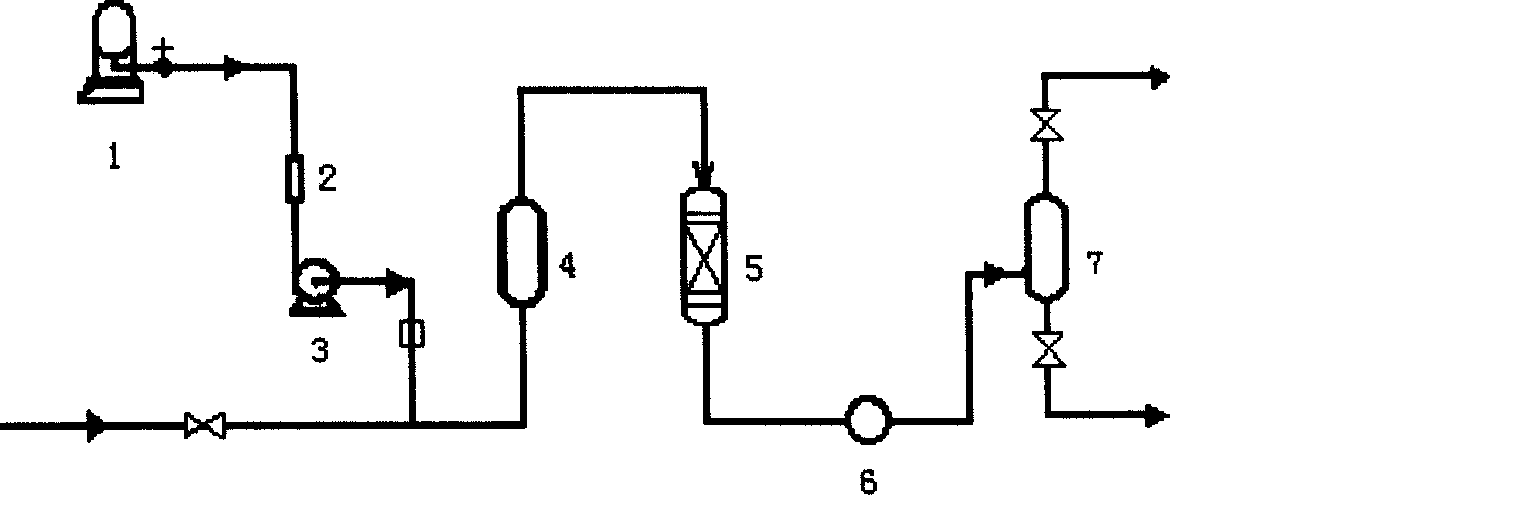

Image

Examples

Embodiment 1

[0018] Put 5g of the prepared ZSM-5-containing catalyst into the constant temperature section of the miniature fixed-bed reactor. The reactor is a stainless steel tube with an inner diameter of φ14mm and a wall thickness of 3mm. The particle size of the catalyst is 2.0mm×3.0mm.

[0019] Using benzene-alcohol mixture containing excess benzene as raw material, at a reaction temperature of 400°C, a pressure of 2.0Mpa, and an ethanol weight space velocity of 2h -1 , the reaction was carried out under the condition that the molar ratio of benzyl to alcohol was 6:1. After 8 hours of reaction, the reaction results were as follows: the conversion rate of raw material ethanol was 99.95%, the conversion rate of benzene was 16.47%, and the selectivity of ethylbenzene was 96.36%.

Embodiment 2

[0021] Put 5g of the prepared catalyst containing ZSM-5 into the constant temperature section of the miniature fixed-bed reactor, at a reaction temperature of 350°C, a pressure of 2.0Mpa, and an ethanol weight space velocity of 2h -1 , the reaction was carried out under the condition that the molar ratio of benzyl to alcohol was 6:1. After 8 hours of reaction, the reaction results were as follows: the conversion rate of ethanol was 99.90%, the conversion rate of benzene was 16.03%, and the selectivity of ethylbenzene was 96.12%.

Embodiment 3

[0023] Put 5g of the prepared catalyst containing ZSM-5 into the constant temperature section of the miniature fixed bed reactor, at a reaction temperature of 450°C, a pressure of 2.0Mpa, and an ethanol weight space velocity of 2h -1 , The reaction was carried out under the condition that the molar ratio of benzyl to alcohol was 6:1. After 8 hours of reaction, the reaction results were as follows: ethanol conversion rate was 99.99%, benzene conversion rate was 16.49%, and ethylbenzene selectivity was 95.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com