Method for anchoring coal mine tunnel bottom plate

An anchoring method and technology for coal mine roadways, which are applied in tunnels, tunnel linings, installation of bolts, etc., can solve problems such as repeated repairs of roadways, and achieve the effects of avoiding repeated repairs, saving labor, and low investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

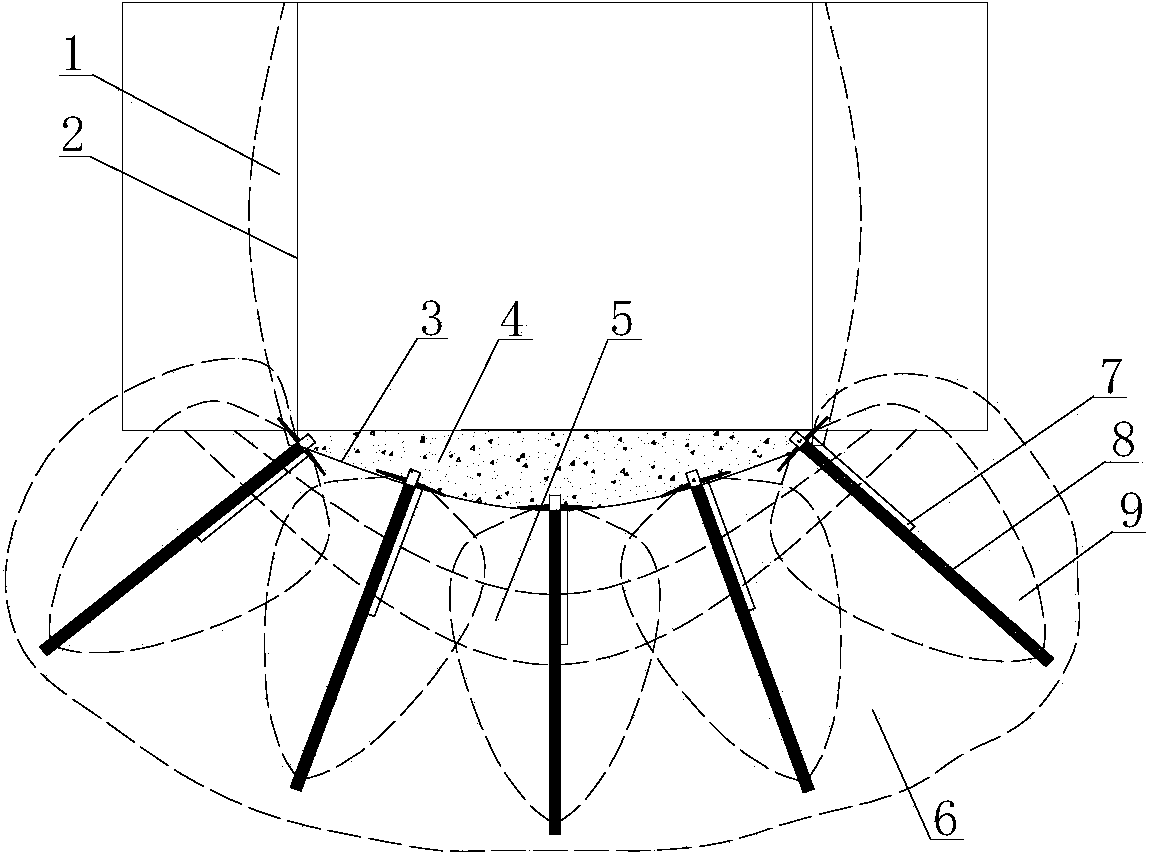

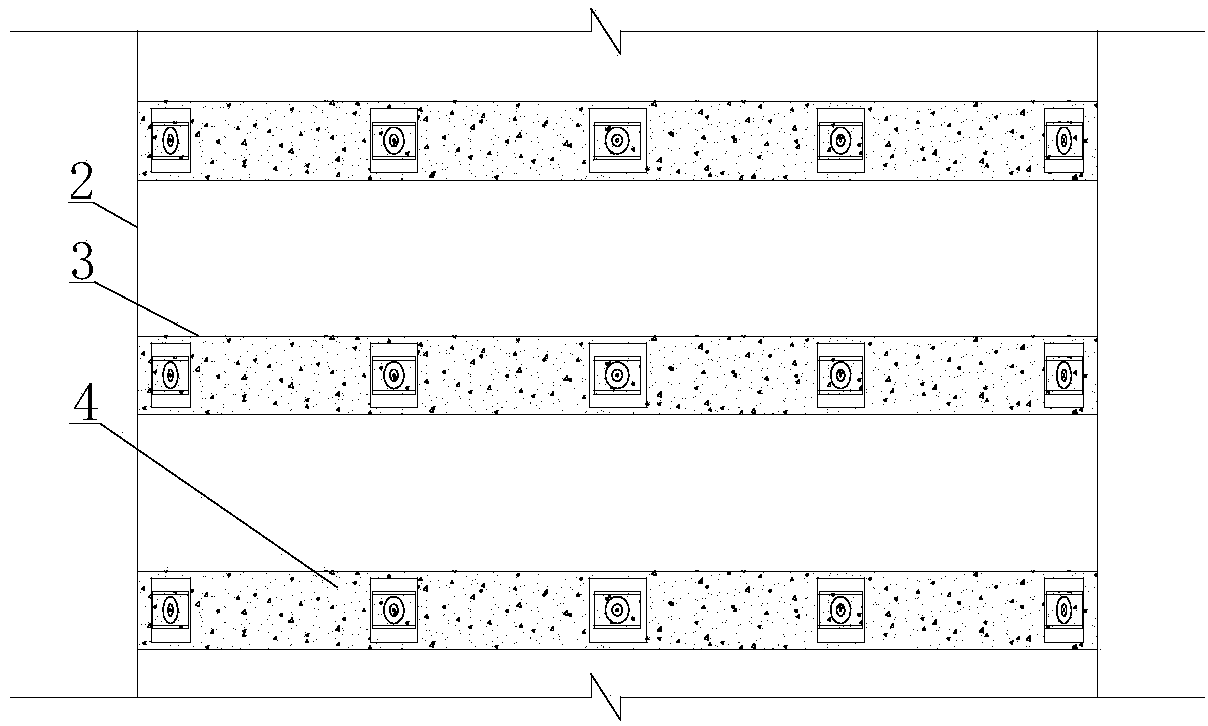

[0039] see Figure 1-2 , has shown the anchoring method for coal mine roadway floor of the present invention.

[0040] The anchoring method for the bottom plate of the coal mine roadway comprises the following steps:

[0041] Step 1, digging a plurality of parallel anti-arch grooves 3 on the roadway floor;

[0042] Wherein, the reverse arched groove 3 is semi-elliptical and can be arranged perpendicular to the axis of the roadway. In some preferred embodiments, the width is about 300-500 mm.

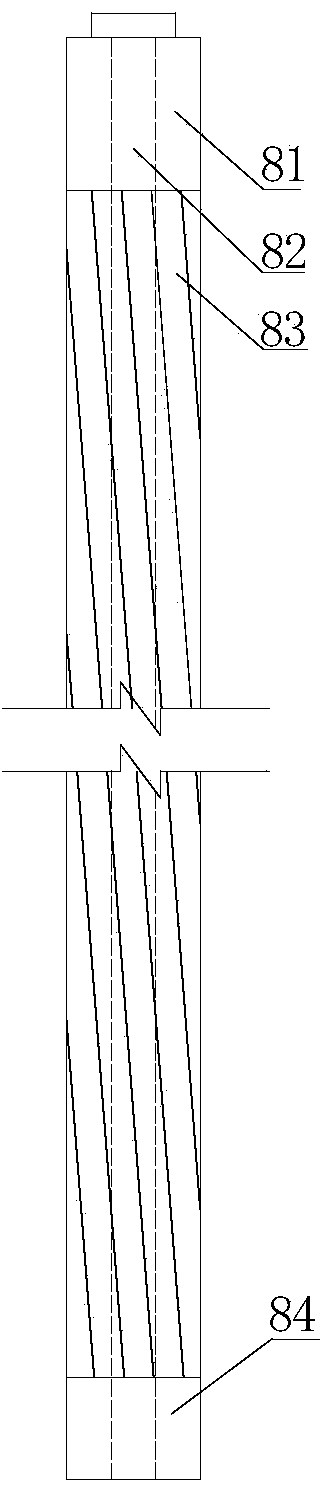

[0043] Step 2: Set a plurality of anchor cable boreholes perpendicular to the arc of the bottom of the groove in the reverse arched groove 3, and lower the hollow grouting anchor cable 8 bound with the grouting pipe 7 in each anchor cable borehole And seal the hole, form a pressure-bearing arch structure through grouting and anchor cable prestressing, and set a braid at a distance from the orifice to seal the hole with cementitious material.

[0044] Wherein, when the anti-arched groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com