Patents

Literature

31results about How to "Removal in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

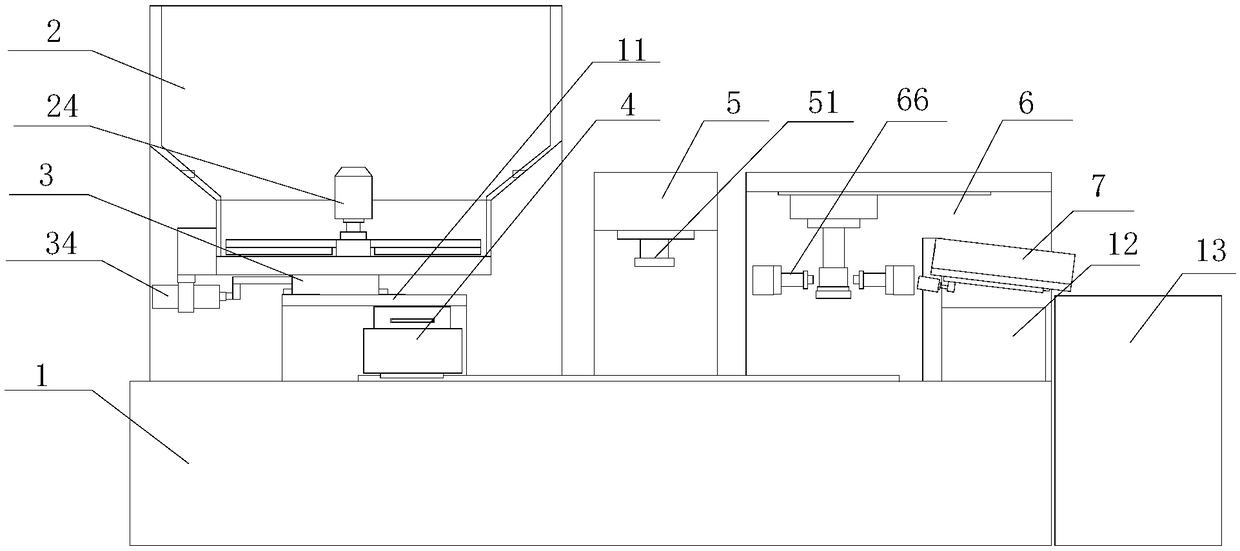

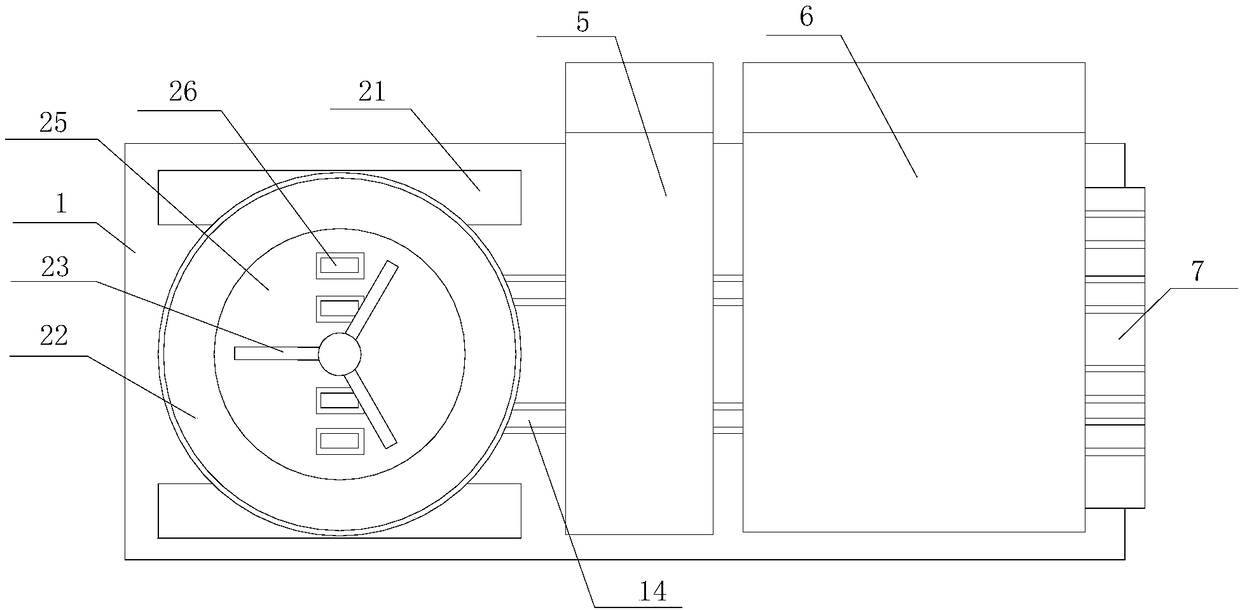

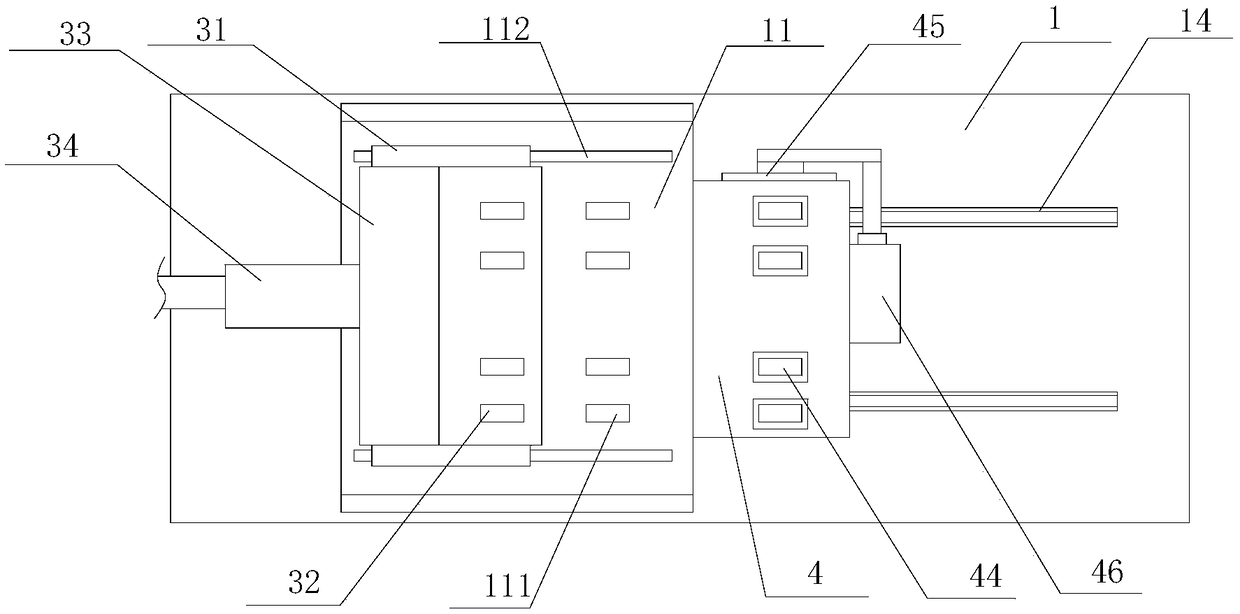

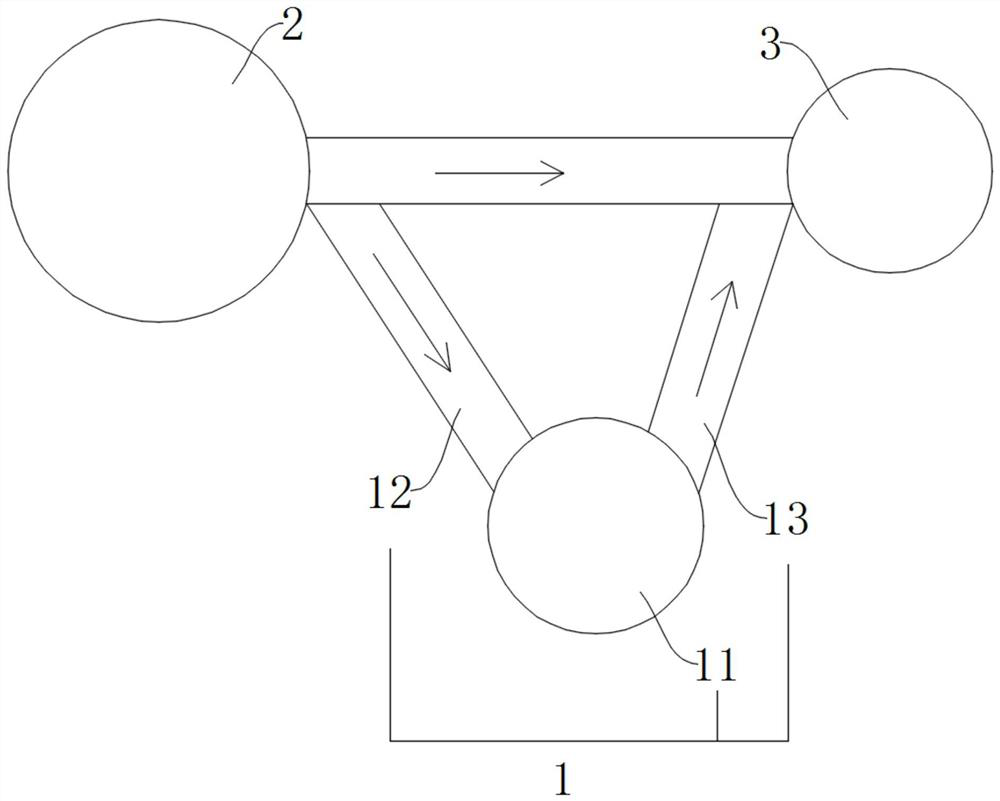

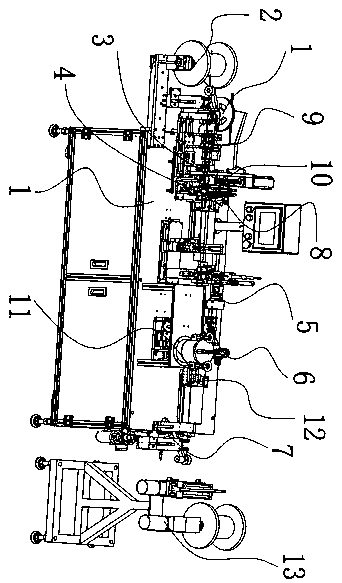

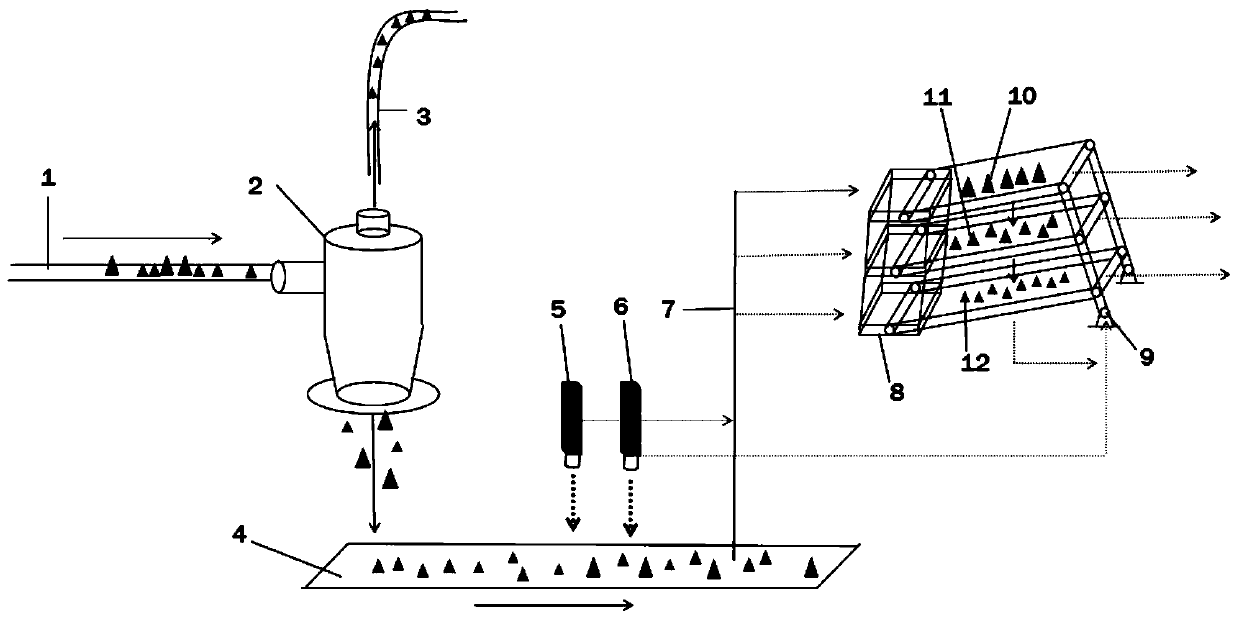

Device for on-line detection and classification of fiber tripping defects of chemical fiber spindles and detection and classification method thereof

ActiveCN109454006ADoes not affect normal productionClear "identityImage enhancementImage analysisFiberClassification methods

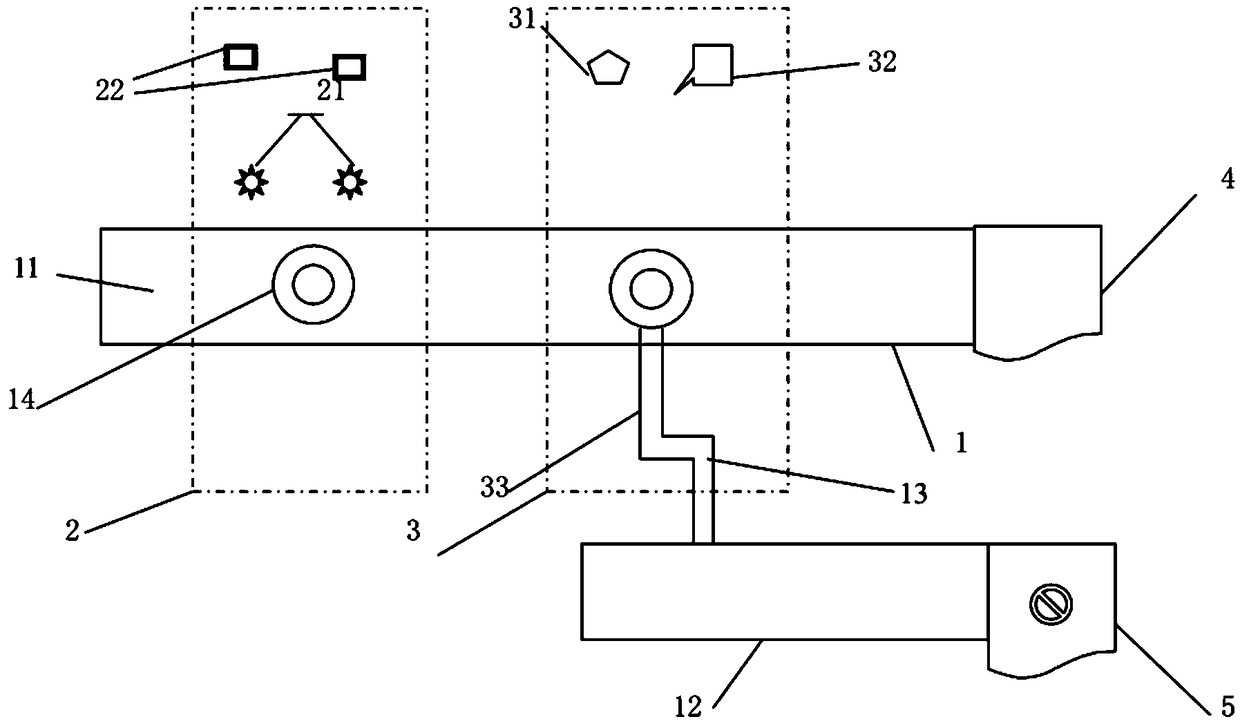

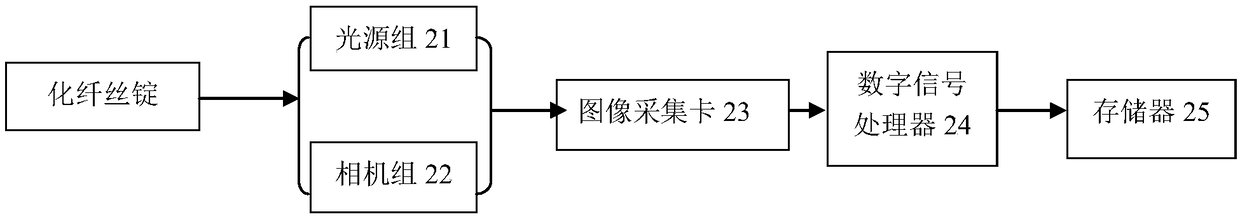

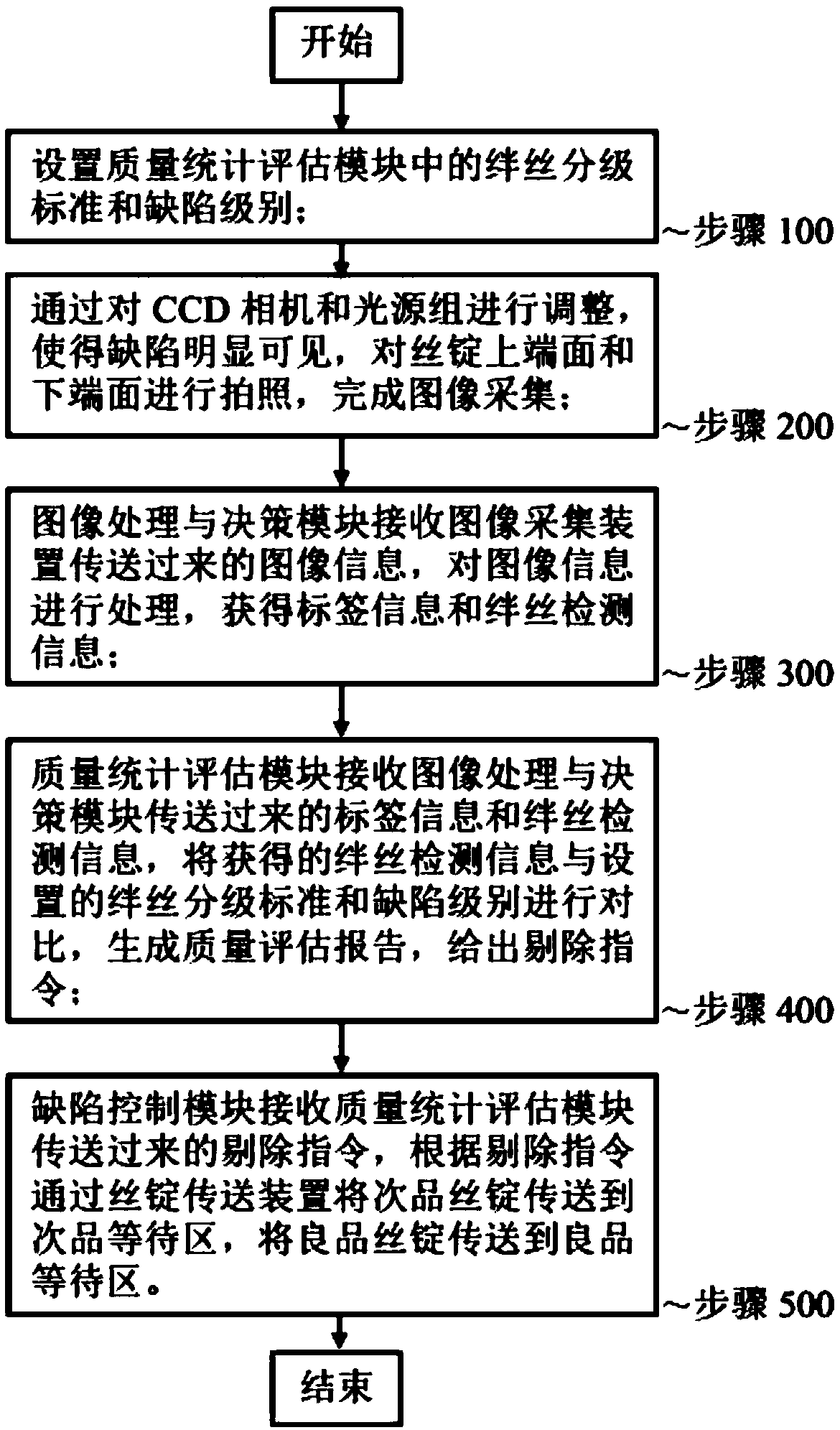

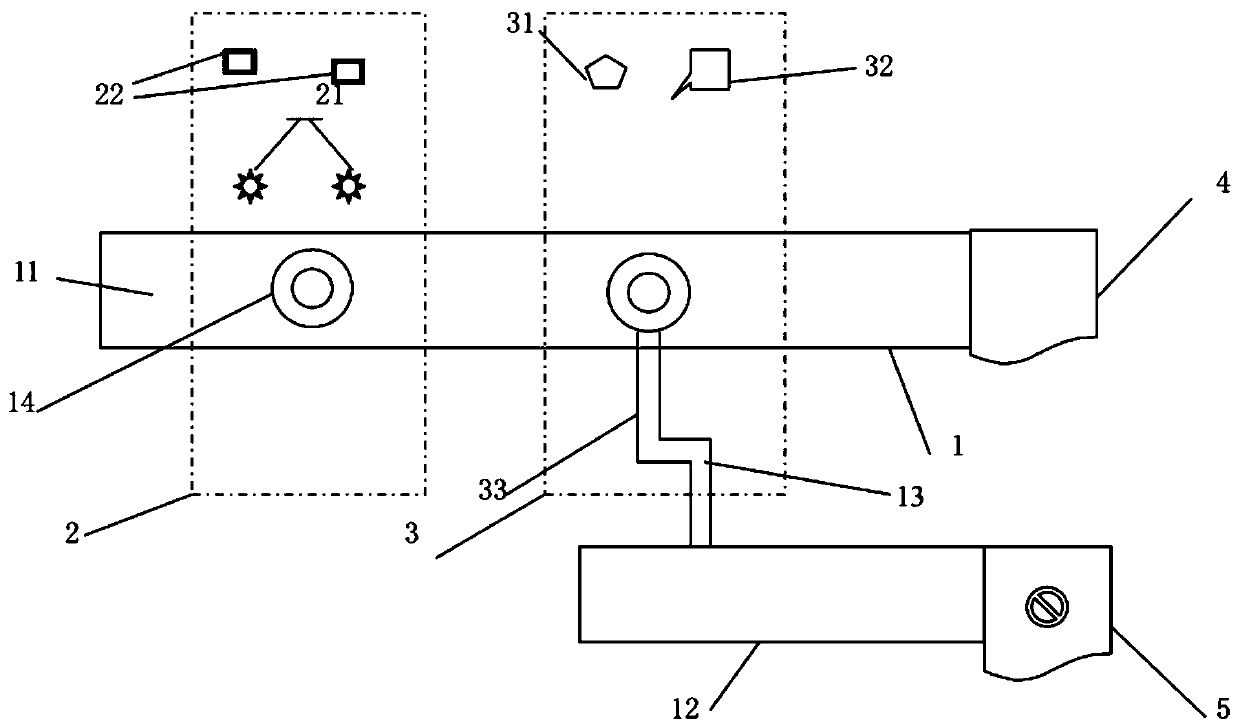

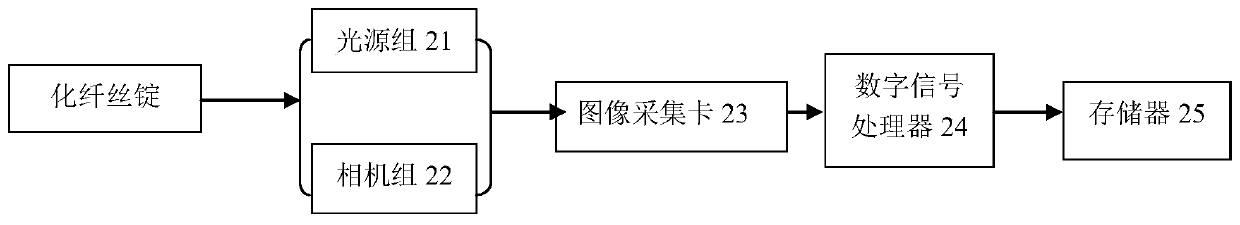

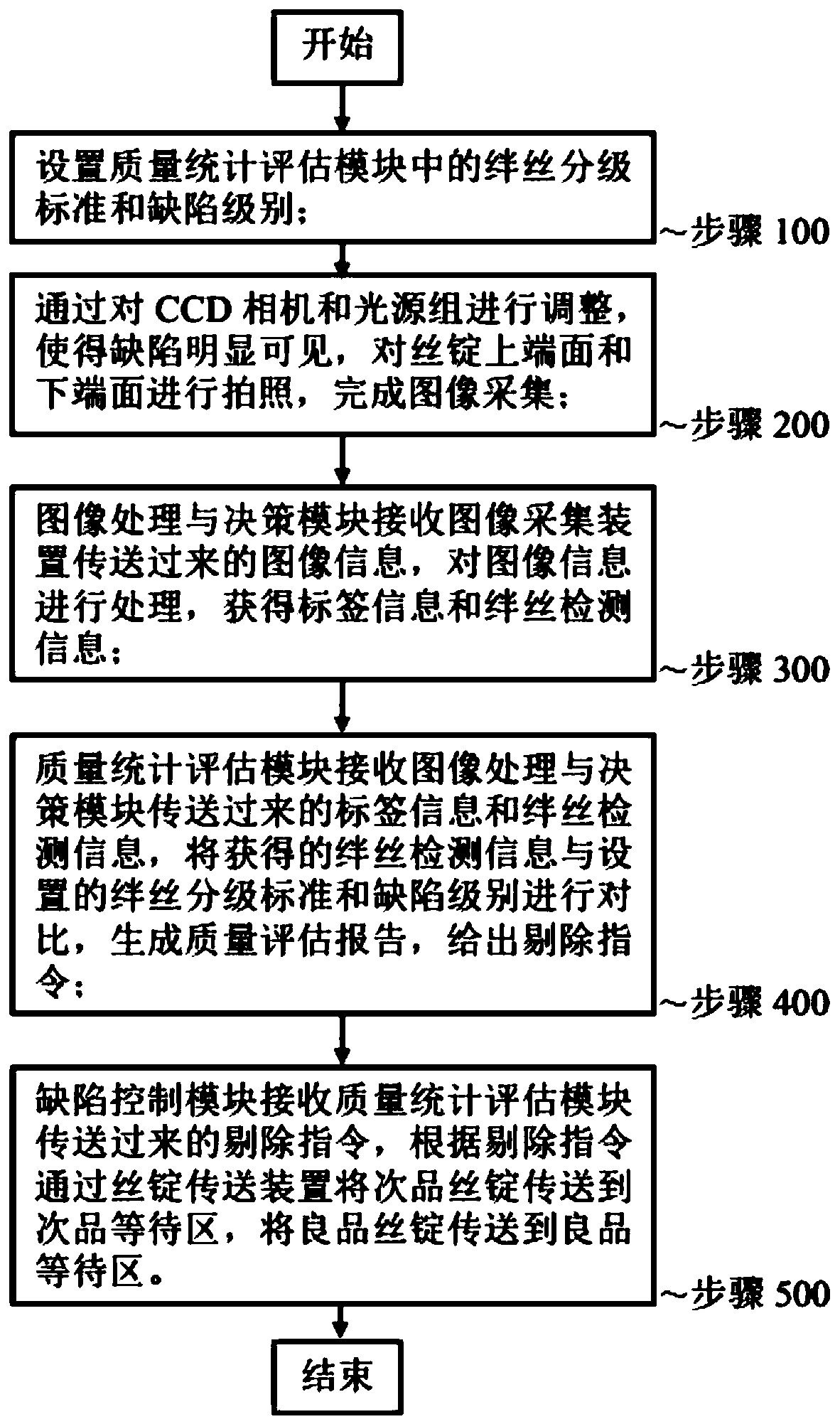

The invention discloses a device for on-line detection and classification of fiber tripping defects of chemical fiber spindles. The device comprises a spindle conveying device, an image acquisition device and a defect elimination module which are positioned on the spindle conveying device, and a good product waiting area and a bad product waiting area which are connected with the spindle conveyingdevice; the defect elimination module comprises an image processing and decision module, a quality statistical evaluation module and a defect control module; the image acquisition device comprises closed dark boxes, LED light source groups, CCD camera groups, image acquisition cards, digital signal processors and memories; the closed dark boxes are arranged above and below the silk ingot conveying device; and the LED light source groups, the CCD camera groups, the image acquisition cards, the digital signal processors and the memories are arranged in the closed dark boxes. The device has thefollowing beneficial effects that collected silk ingot images are processed by combining machine vision and an image processing technology, the interference number and morphological characteristics ofthe tripping fibers and interference fibers can be simultaneously detected, the fiber ingots with the fiber tripping defects can be detected by using detected fiber tripping information, and a sourcecan be traced by using statistical interference information.

Owner:杭州慧知连科技有限公司

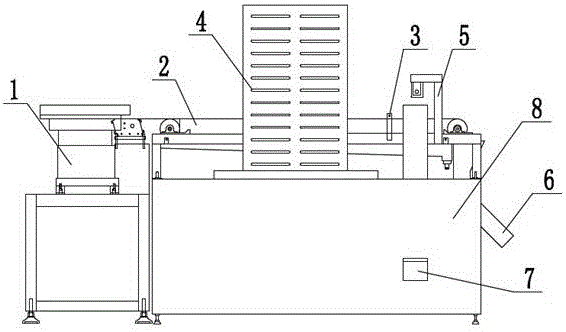

Weighing and sorting metering device

InactiveCN107344640ARemoval in timeSimple structureConveyorsControl devices for conveyorsDisplay deviceEngineering

The invention discloses a weighing, sorting and metering device, which comprises a feeding conveyor belt, a weighing conveyor belt and a rejecting conveyor belt. A first infrared sensor corresponding to the position is suspended above the left end of the weighing conveyor belt. A weighing system is added between the lower part of the transmission belt and the pressure-bearing support. The weighing system includes a pressure sensor, a control box and a display. The pressure sensor is connected to the lower part of the support of the weighing transmission belt. A second infrared sensor corresponding to the position is provided, and a rejecting device is installed on the right side of the second infrared sensor. Non-conforming product storage bag. The invention adopts the design of intelligent weighing and rejecting, which can remove the products with unqualified weight in time, has a simple structure, improves the efficiency of the sorting work, and satisfies the requirements of the work.

Owner:JIAYUN DAILY NECESSITIES HANGZHOU

Bearing part automatic sorting method

InactiveCN106493090AClear imagingGuaranteed accuracyOptically investigating flaws/contaminationSortingEngineeringLocation detection

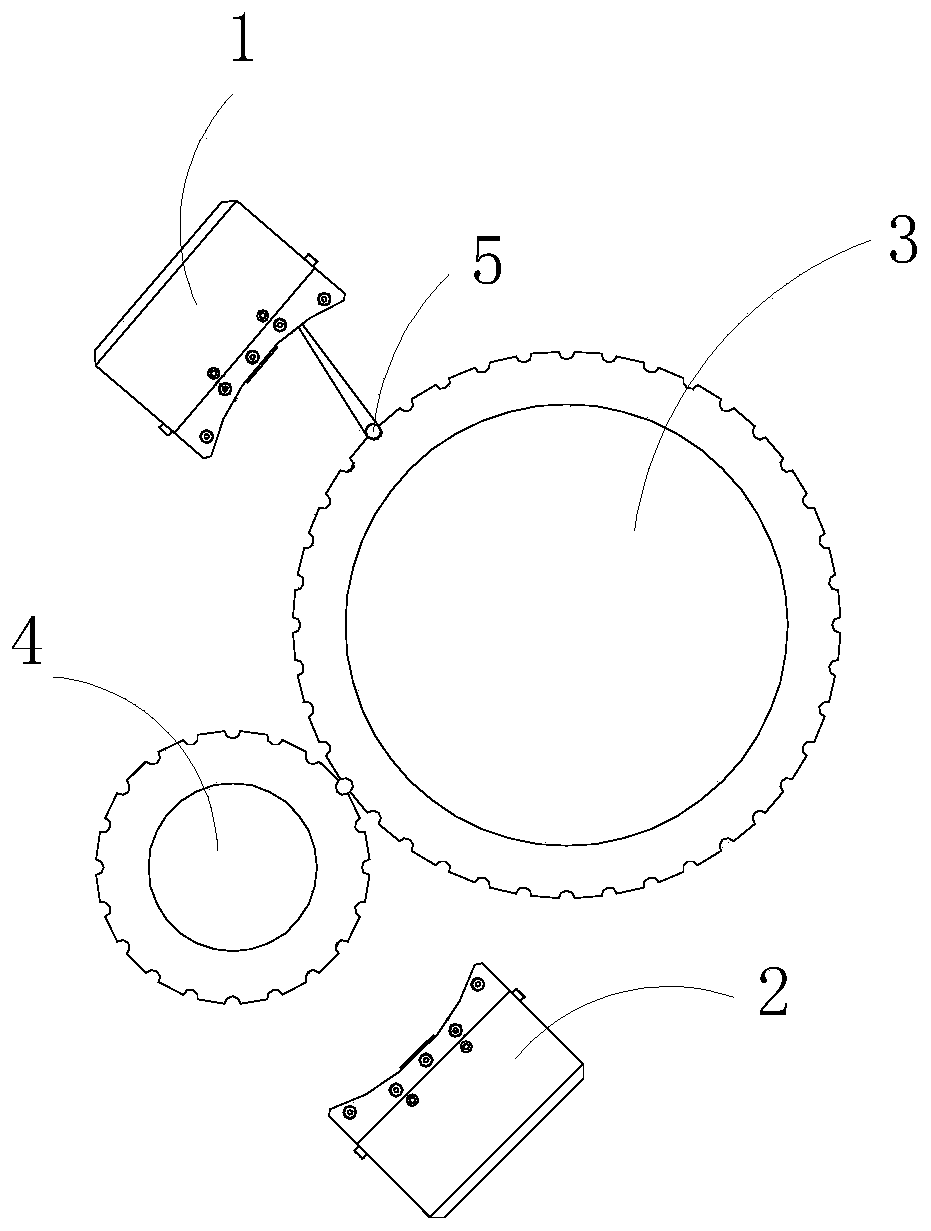

The invention discloses a bearing part automatic sorting method. The bearing part automatic sorting method comprises the following steps: a conveying device conveys bearing parts to be detected to a detecting area; after the detected bearing parts are conveyed to the detecting area, a position detecting sensor is triggered to send position signals of the bearing parts to be detected to a visual detecting system in real time; the visual detecting system obtains images of the bearing parts to be detected according to position information of the bearing parts to be detected; the obtained images are compared with standard data of the bearing parts to judge if the bearing parts are qualified products; and then, the sorting is performed. The bearing part automatic sorting method detects the surface defects of the bearing parts by a visual mode, is clear in imaging, can guarantee the detecting accuracy, and meanwhile, adopts a belt conveying structure capable of continuously detecting to improve the detecting efficiency.

Owner:北京金贝诺科技有限公司

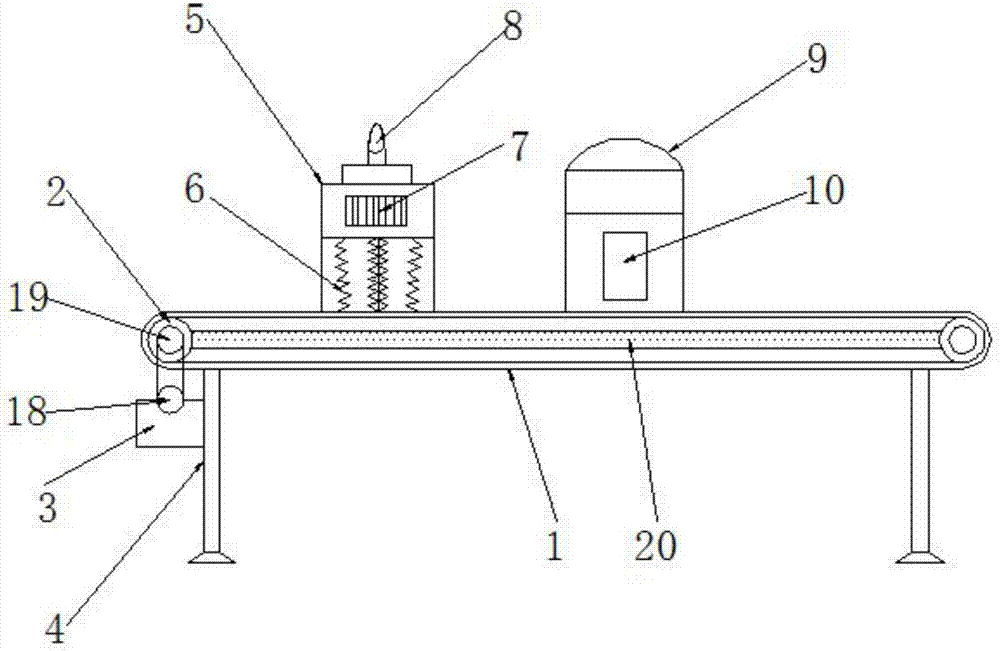

Detecting and removing machine for bubble cap capsule plate containing capsules

PendingCN107020250AEasy to detectAchieve cullingMaterial analysis by optical meansSortingEngineeringDetection rate

The invention discloses a detecting and removing machine for a bubble cap capsule plate containing capsules. The detecting and removing machine comprises a machine frame and at least one set of capsule detecting and removing assembly. Each set of the capsule detecting and removing assembly comprises a conveying device, a detecting device, a removing device and a control device. Each conveying device sequentially comprises an upper conveying device body and a lower conveying device body according to the direction of the capsules. Each detecting device comprises an industrial camera, a light source, a first counting sensor and a second counting sensor. Each industrial camera is installed on a camera support, and each light source is installed on a light source support. The camera supports and the light source supports are both installed on the machine frame. The industrial cameras and the light sources are both located above upper conveying belts. The first counting sensors, the second counting sensors and the industrial cameras are all connected with the corresponding control devices. Each removing device comprises a removing base and an overturning power device. By means of the detecting and removing machine, the detection rate of unqualified products is guaranteed.

Owner:赵亮

Garbage pickup device and cleaning robot thereof

InactiveCN108937737ARemoval in timeExtended service lifeCarpet cleanersFloor cleanersEngineeringLarge particle

The invention discloses a garbage pickup device and a cleaning robot thereof. The garbage pickup device comprises a rolling brush, a removing device, a dust storage box and cleaning motors; the rolling brush is fixedly arranged at the lower right end of a shell, the removing device is movably installed in a dovetailed groove formed in the portion, located above the rolling brush, of the shell, thelower end off the shell is provided with a main sucking port used for sucking large-particle garbage, the dust storage box is movably installed at the left end of the shell, a sucking motor is fixedly arranged between the dust storage box and the shell, and the cleaning motors are fixedly arranged at the lower end of the dust storage box. According to the garbage pickup device, through the arrangement of the removing device and an auxiliary sucking port, garbage winding the rolling rush can be timely removed, the cleaning effect of the device is improved, the load of the motors is lowered, and the service life of the motors is prolonged; through the formation of the main sucking port, the large-particle garbage can be effectively adsorbed, and the practicability is high; through the arrangement of the cleaning motors and cleaning discs, the ground is cleaned multiple times, and the cleaning effect of the device is effectively improved.

Owner:安徽爱依特科技有限公司

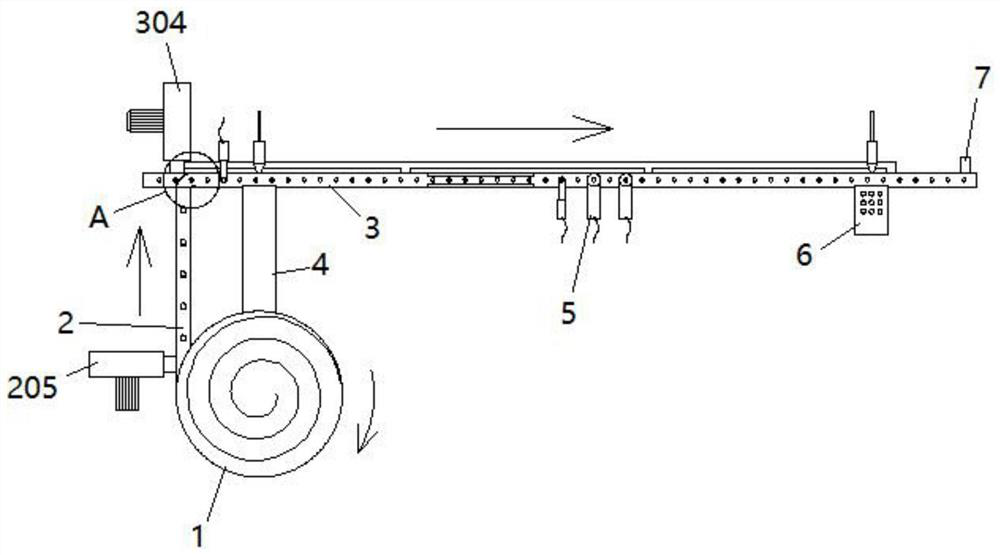

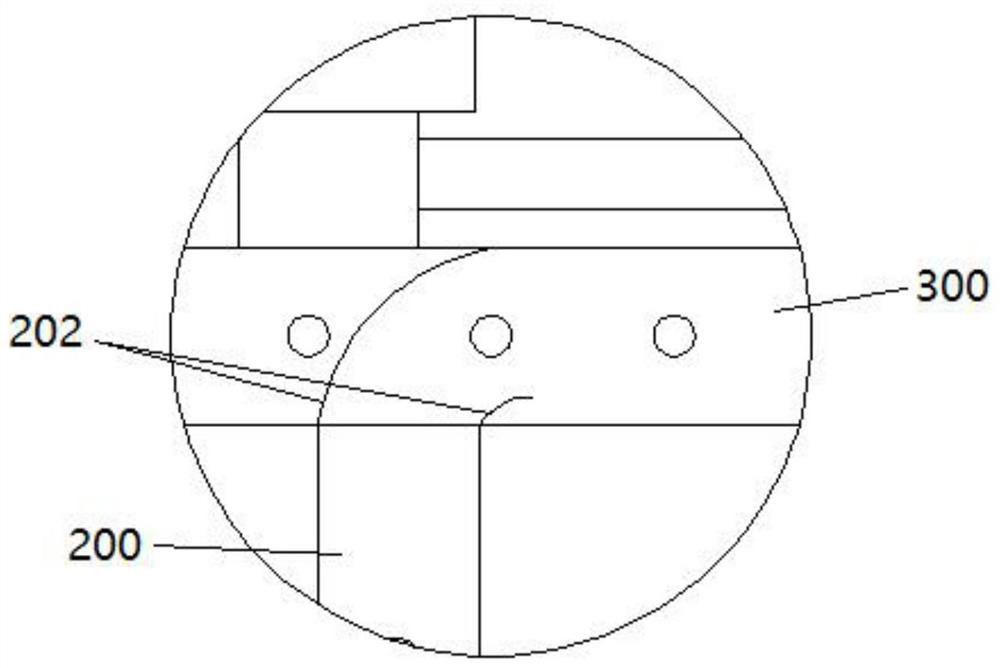

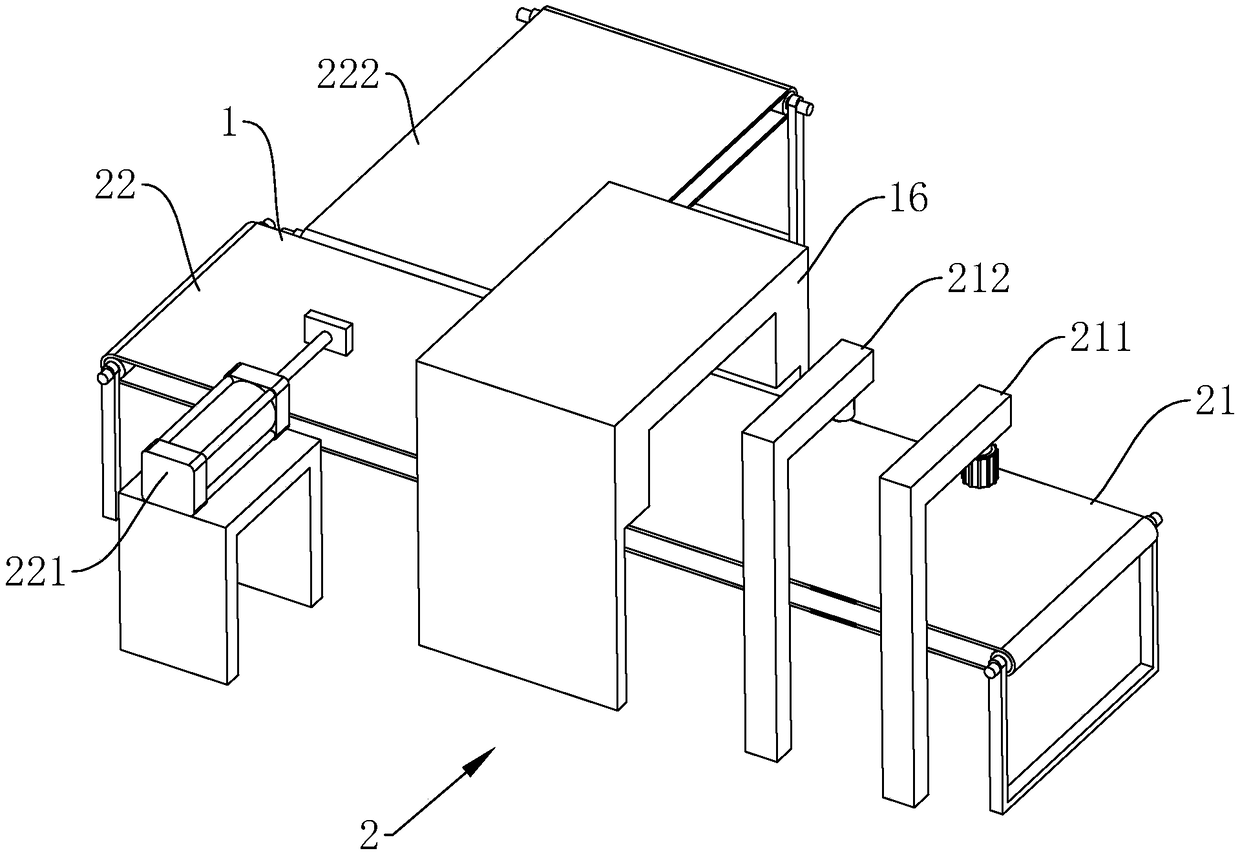

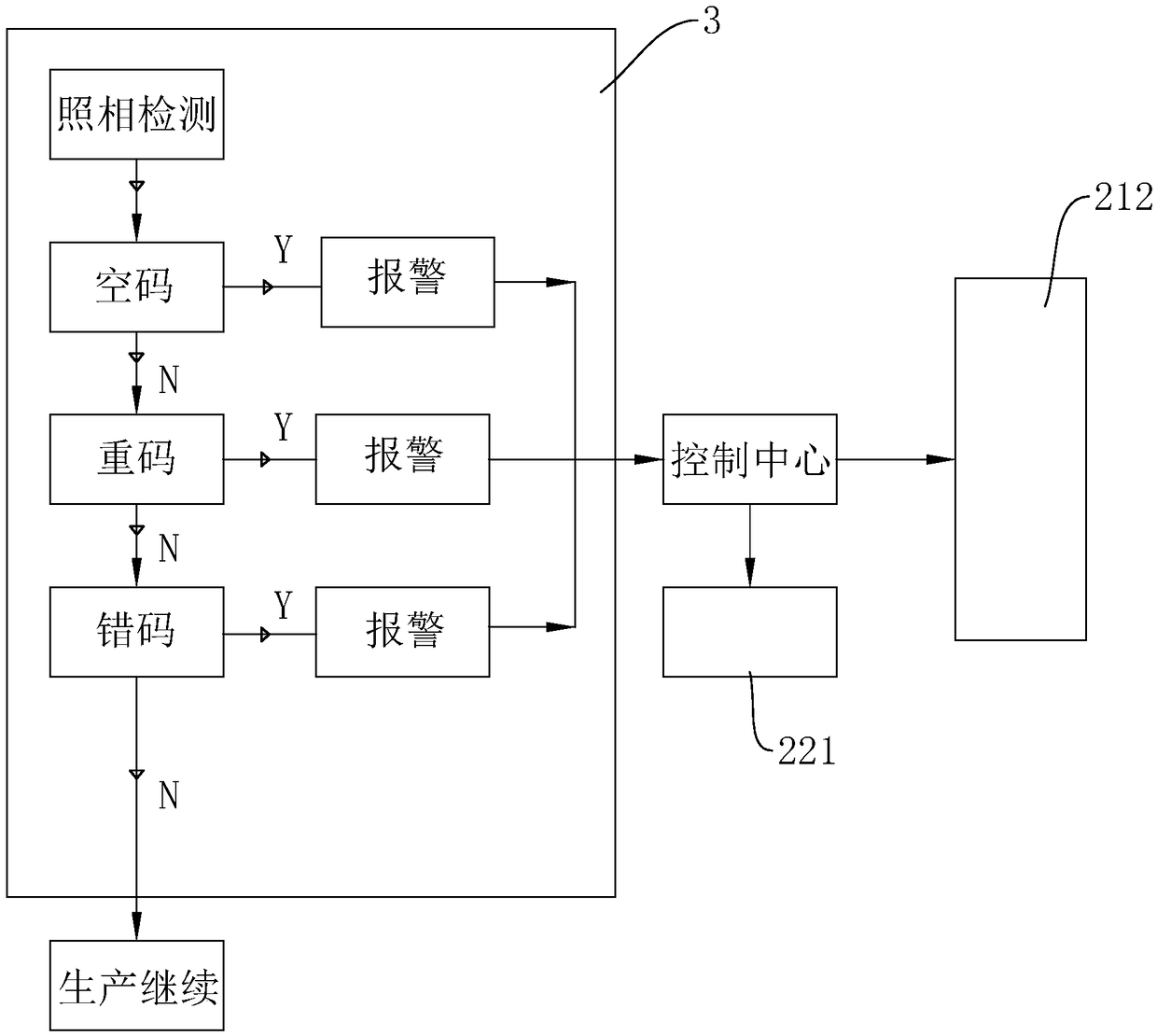

Two-dimensional code printing machine applied to bottle cap

InactiveCN111703838ASimple structureEasy to implementControl devices for conveyorsLaser beam welding apparatusProcess engineeringAssembly line

The invention discloses a two-dimensional code printing machine applied to a bottle cap. The two-dimensional code printing machine applied to the bottle cap comprises a vibrating disk, a first conveying mechanism, a second conveying mechanism, a back blowing mechanism, a two-dimensional code printing and detecting mechanism, a defective product removing mechanism and an encoder used for detectingthe conveying speed of a conveying belt, wherein the first conveying mechanism mainly comprises a conveying panel and a plurality of air blowing holes formed in the conveying panel and used for blowing air backwards, the second conveying mechanism mainly comprises the conveying belt and a plurality of air suction holes formed in the conveying belt, the back blowing mechanism mainly comprises a first photoelectric switch, a first spray head and a material return pipe, the two-dimensional code printing and detecting mechanism mainly comprises a second photoelectric switch, a laser printer and acamera; and the defective product removing mechanism mainly comprises a second spray head and a material receiving pipe. On the basis of fusing the laser printer, the printing precision can be ensured, the rate of certified products is improved, and automatic, convenient and assembly line type production is achieved.

Owner:ANHUI BAISHIJIA PACKING CO LTD

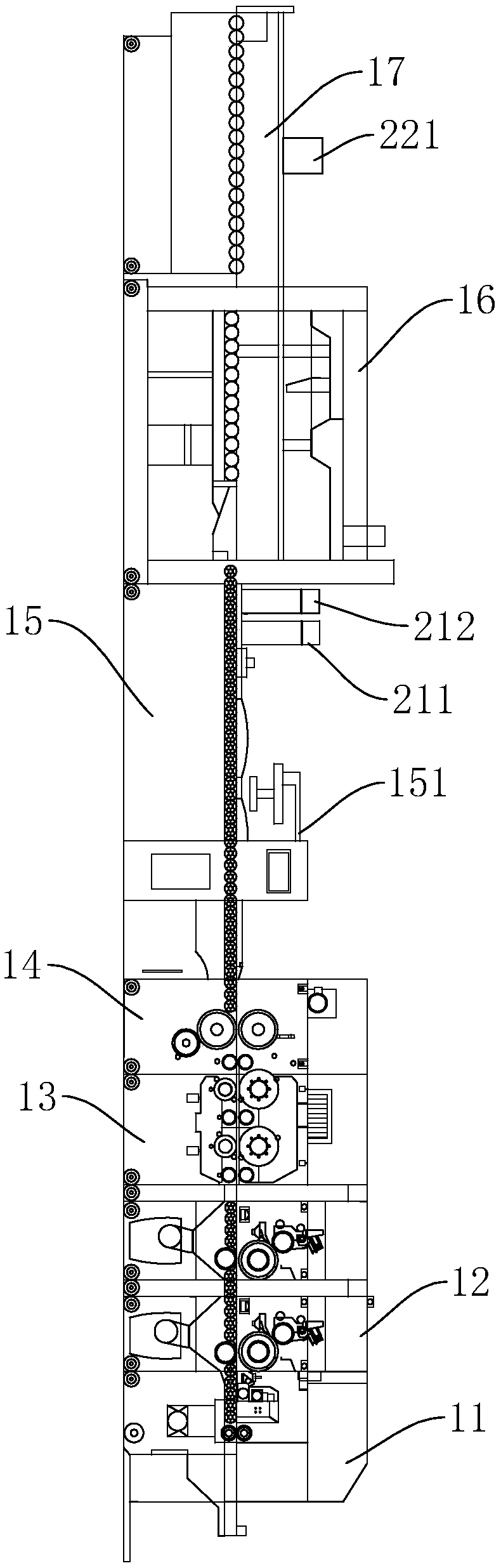

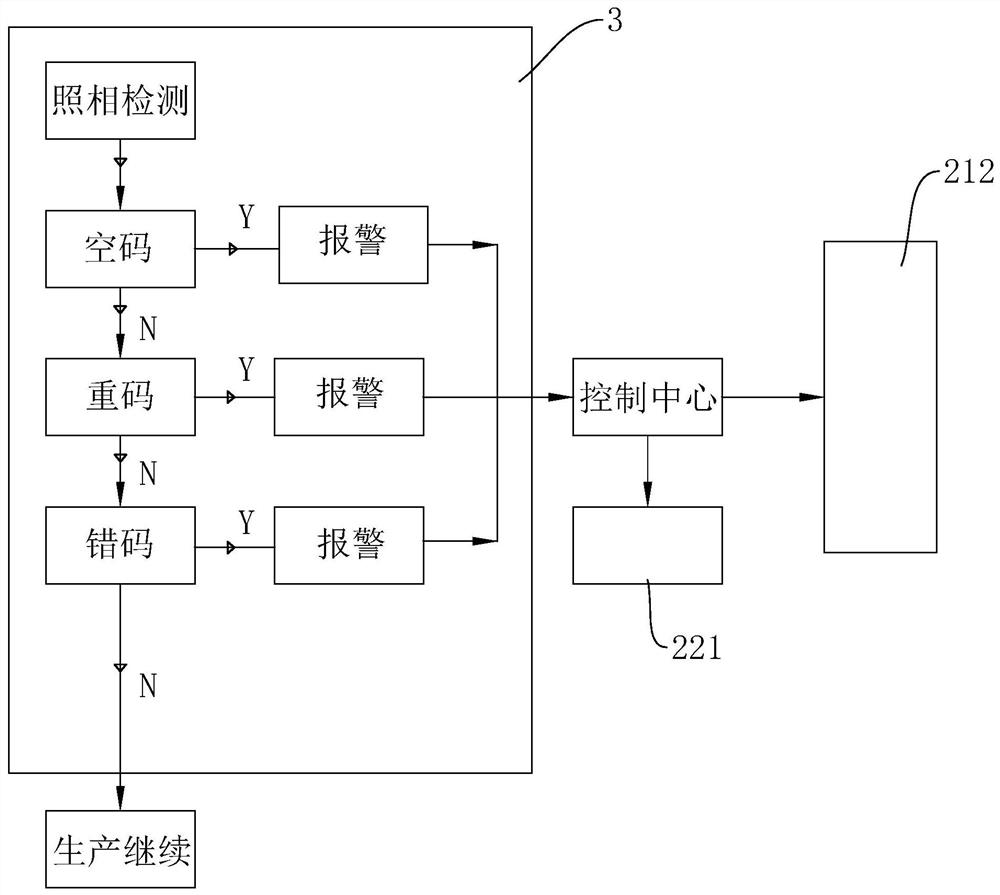

Corrugated case printing-adhering production line with high-speed code-spraying function

ActiveCN109334102ARemoval in timeIncrease productivityPaper-makingBox making operationsProduction lineError reporting

The invention discloses a corrugated case printing-adhering production line with a high-speed code-spraying function, belongs to the field of corrugated case production, and aims to provide the corrugated case production line capable of on-line rejecting defective code-spraying products, saving manpower and material resources, and improving the production efficiency. The invention has the technical scheme that the corrugated case printing-adhering production line with the high-speed code-spraying function comprises a tank feeding conveyor belt, a paper feeding part, a printing part, a slottingand line pressing part, a die cutting part, a folding and case-adhering part, a stacking part and a counting and bundling part, wherein the paper feeding part, the printing part, the slotting and line pressing part, the die cutting part, the folding and case-adhering part, the stacking part and the counting and bundling part are sequentially arranged along the conveying direction of the tank feeding conveyor belt; a code spraying mechanism is arranged on the folding and case-adhering part; a defective product rejection part is further arranged additionally and comprises a detection platform and a rejection platform; the detection platform is located between the folding and case-adhering part and the stacking part; a detection device for detecting abnormal codes is arranged on the detection platform; and after the rejection platform is arranged on the counting and bundling part along the conveying direction of the tank feeding conveyor belt, a rejection device is arranged on the rejection platform, so that when the detection device sends out an error reporting command, the rejection device receives the command and rejects the defective products.

Owner:合肥丹盛包装有限公司

Anti-interference cigarette appearance quality online detection device and method

InactiveCN111000286AAvoid false detectionAvoid cullingCigarette manufactureEngineeringMechanical engineering

Owner:阚晖 +1

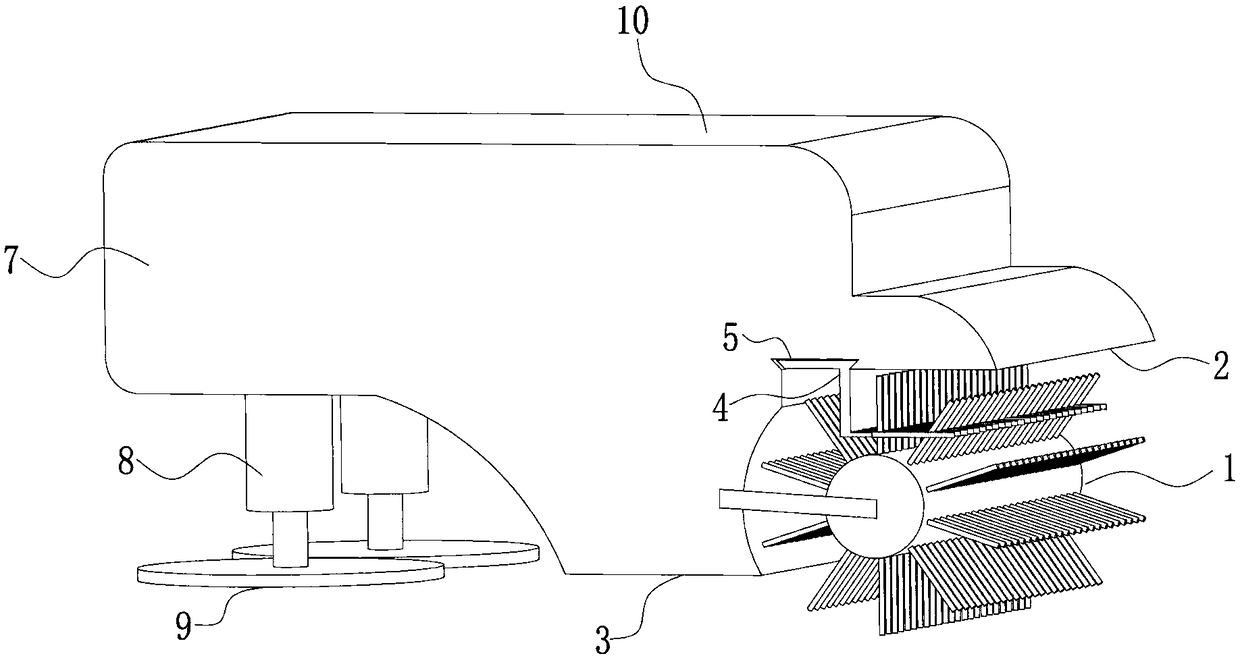

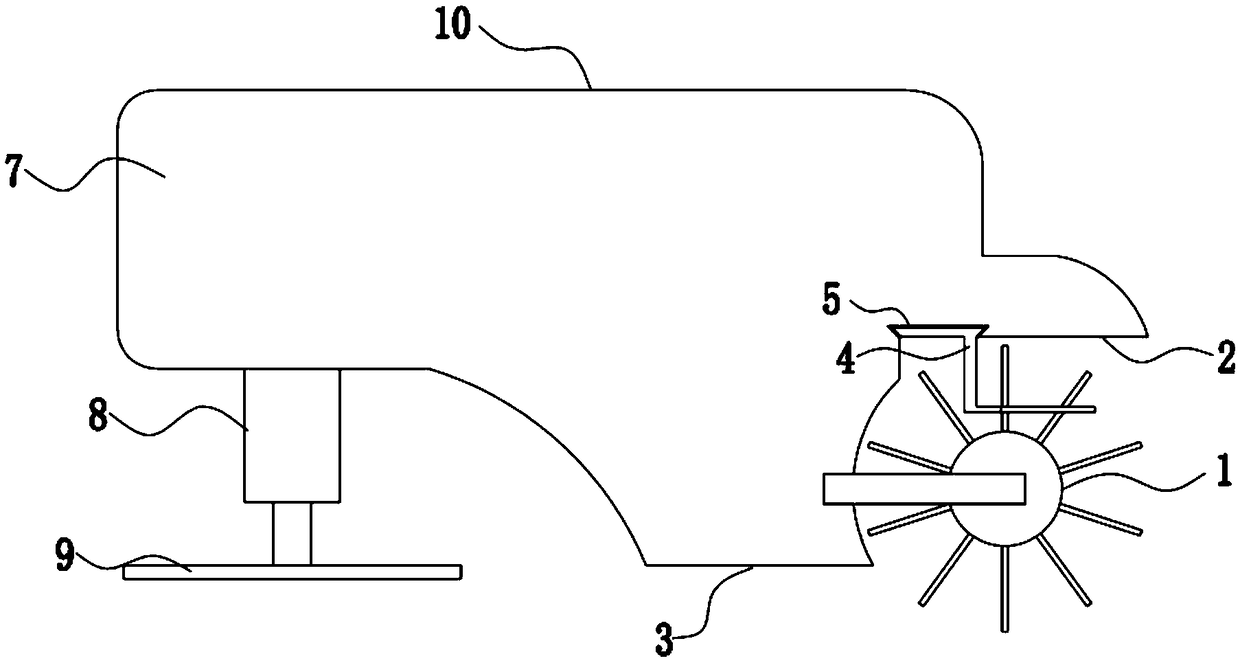

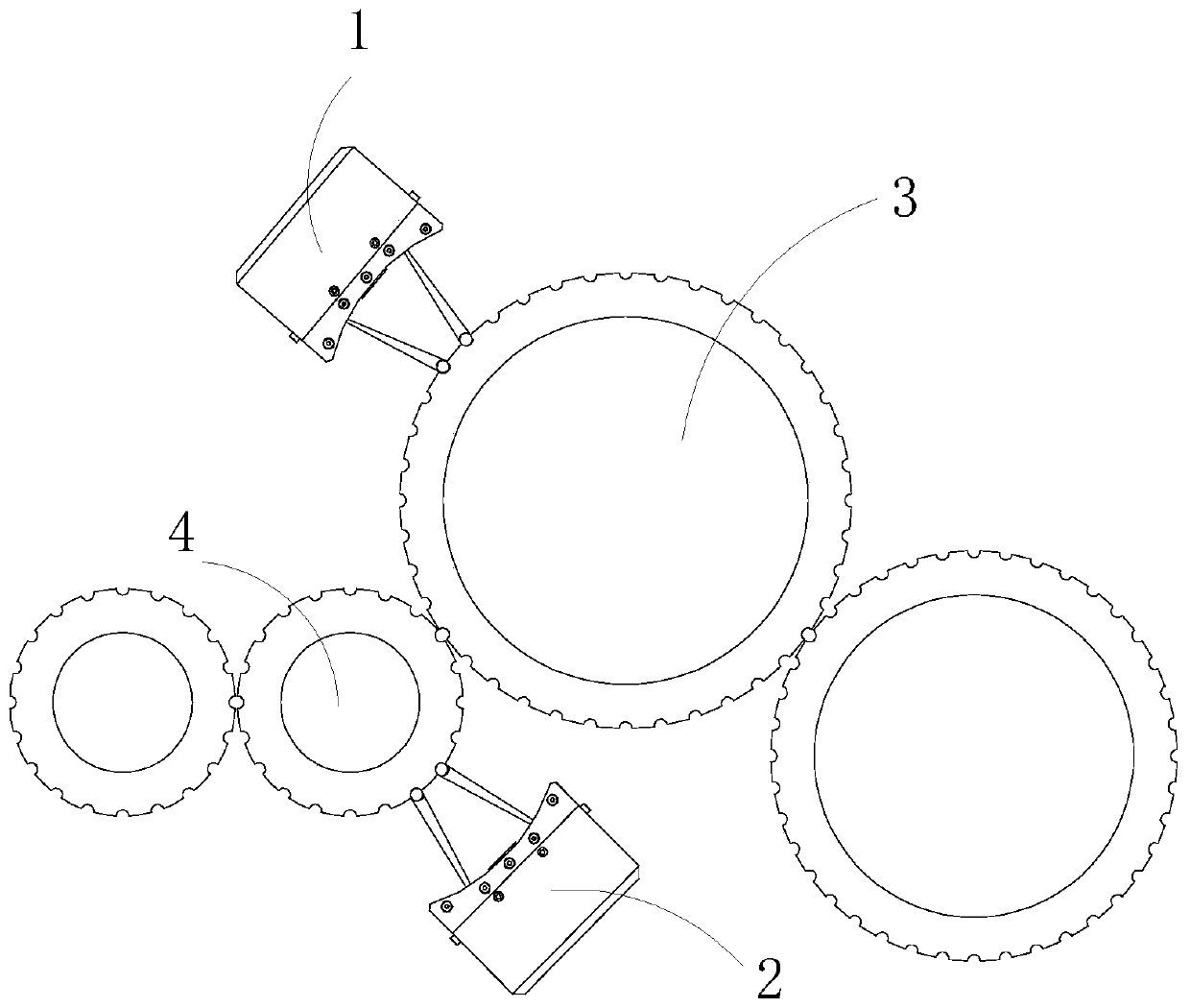

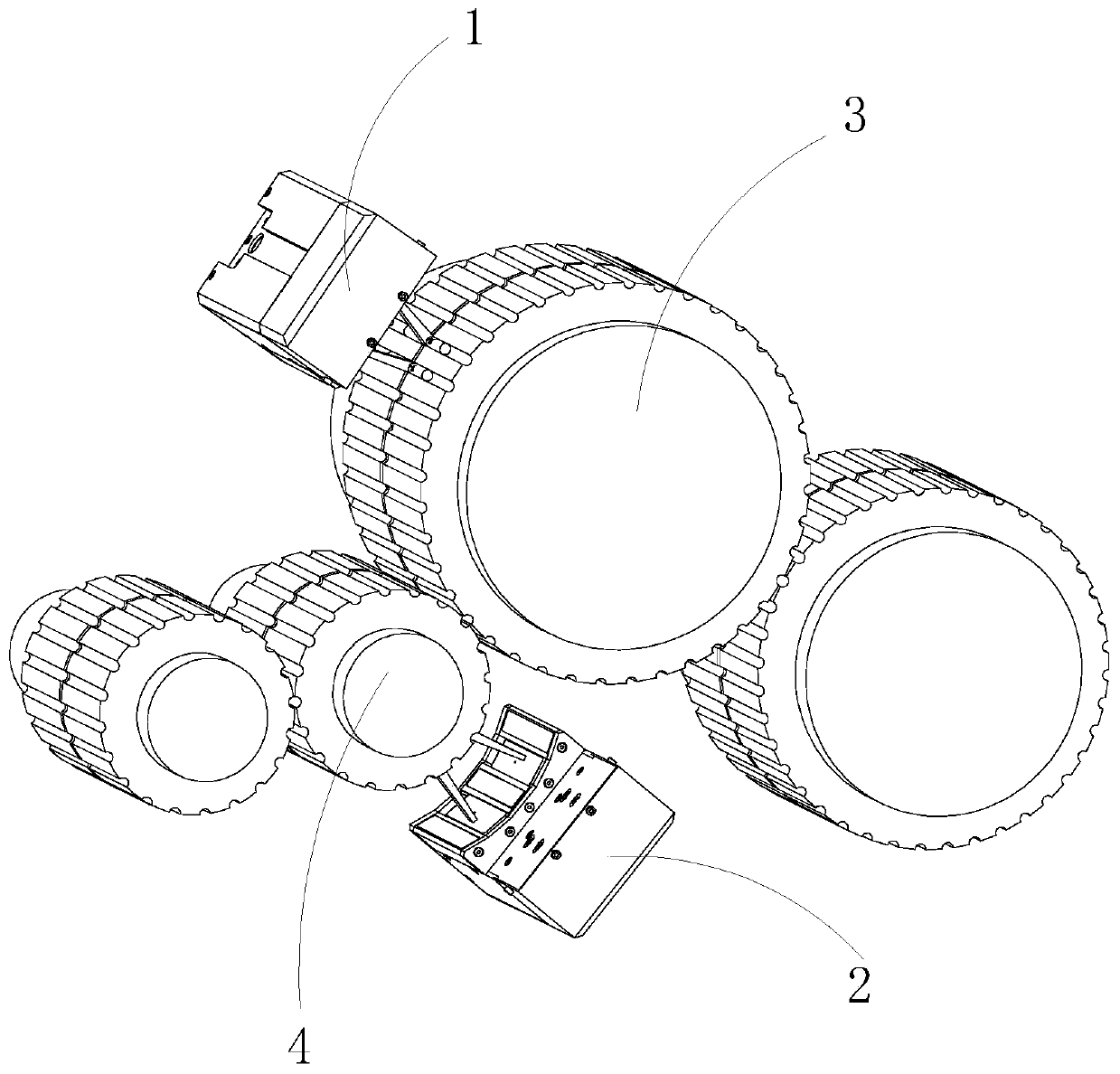

Capsule real-time inspection method with double detection

ActiveCN105241890AImprove drug qualityRemoval in timeOptically investigating flaws/contaminationSortingEngineeringMaster controller

The invention relates to a capsule real-time inspection method with double detection, which comprises the following steps: 1) providing a capsule real-time test platform with double detection, which includes a near-infrared detection mechanism, a visible light detection mechanism and a main controller, wherein the near-infrared detection mechanism and the visible light detection mechanism respectively perform defect detection to every capsule and the main controller is respectively connected to the near-infrared detection mechanism and the visible light detection mechanism for determining a capsule rejection strategy according to a defect detection result from the near-infrared detection mechanism and the visible light detection mechanism; and 2) performing inspection with the test platform. According to the method, there are two detection methods are available to detect the capsules, thereby improving reliability of capsule test.

Owner:NANNING FRESH LIFE BIOTECH

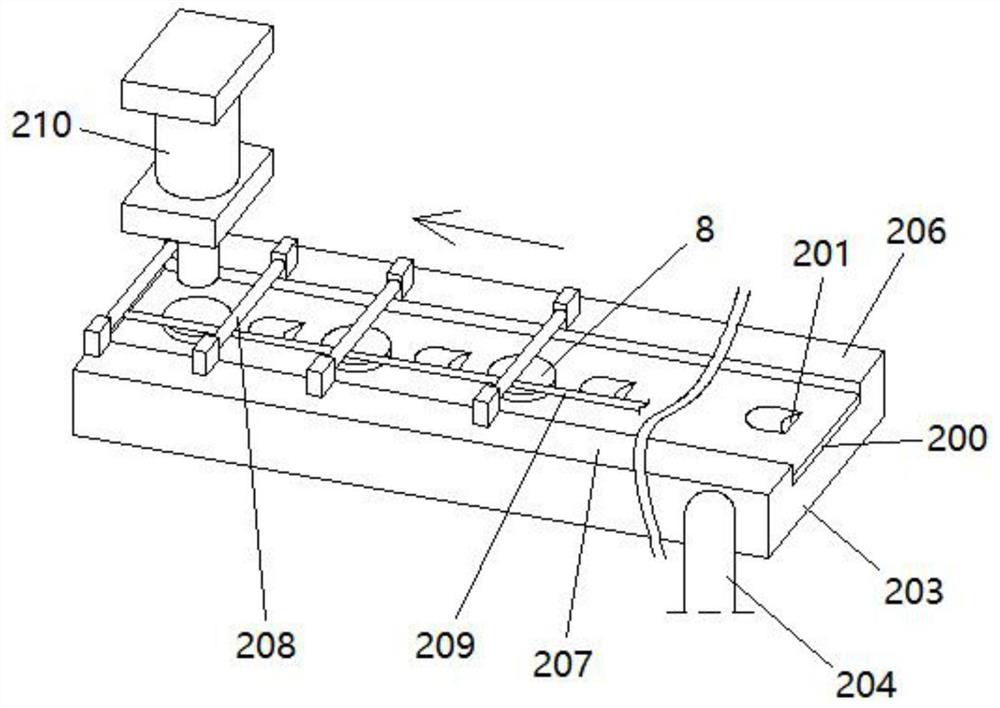

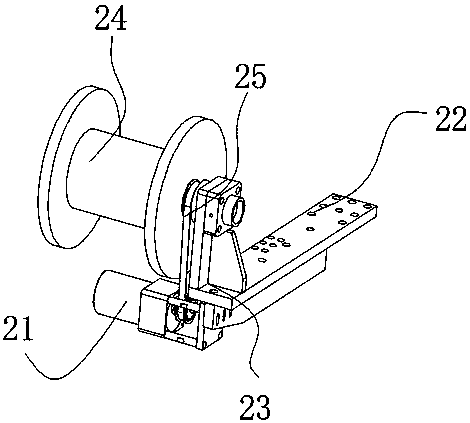

Two-dimensional code printing device for gaskets in bottle caps

ActiveCN111688363AImprove reliabilityImprove work efficiencyTypewritersCommerceProcess engineeringAssembly line

The invention discloses a two-dimensional code printing device for gaskets in bottle caps. The two-dimensional code printing device comprises a feeding mechanism, a material arranging mechanism, a linkage mechanism, a first conveying mechanism, a second conveying mechanism, a blowback mechanism, a two-dimensional code printing and detecting mechanism, a defective product eliminating mechanism andan encoder; the gaskets are conveyed to the second conveying mechanism by the feeding mechanism, the material arranging mechanism and the first conveying mechanism in sequence; the blowback mechanismblows back the gaskets with unsatisfactory distance to the material arranging mechanism; and the two-dimensional code printing and detecting mechanism prints a two-dimensional code on the surface of each gasket, detects the printed gaskets, and eliminates unprinted products and defective products in cooperation with the defective product eliminating mechanism. According to the two-dimensional codeprinting device for the gaskets in the bottle caps, automatic and assembly line type production can be realized, the two-dimensional code stored with product information can be printed on the surfaceof each gasket, the effects of information tracing, marketing popularization and the like can be achieved, the bottle cap built-in two-dimensional code formed thereby has better anti-counterfeiting effect, and the two-dimensional code printing device has the characteristics of high production efficiency, high rate of certified products, short production period, low cost and the like.

Owner:ANHUI BAISHIJIA PACKING CO LTD

Data information acquisition and monitoring method based on Internet of Things

InactiveCN110536110ASolve the problem of insufficient spot checksEasy to operateMemory record carrier reading problemsClosed circuit television systemsProduction lineData information

The invention discloses a data information acquisition and monitoring method based on the Internet of Things. The method comprises the steps of 1, printing a two-dimensional code and an RFID label ofa semi-finished product on each production line through an RFID label printer, tearing off an RFIF label and pasting the RFIF label on the surface of a semi-finished product to obtain a detailed coordinate and a to-be-moved station of each semi-finished product, and step 2, ensuring that stable operation is required when a factory runs through the RFID label, and installing a photoelectric detection sensor at each discharging position on a production line. The invention relates to the technical field of information acquisition, in the data information acquisition and monitoring method based onthe Internet of Things, each ach product is marked through the RFID tag; the semi-finished products are detected in each process through cooperation with the photoelectric detection sensor, detectiondata obtained after detection are uploaded to the product database, the purpose that each product is detected is achieved, the RFID label of the Internet of Things is used in cooperation in the wholeprocess, and the database is used in cooperation to facilitate tracing and retrieval of the products in the later period.

Owner:杭州诚億科技有限公司

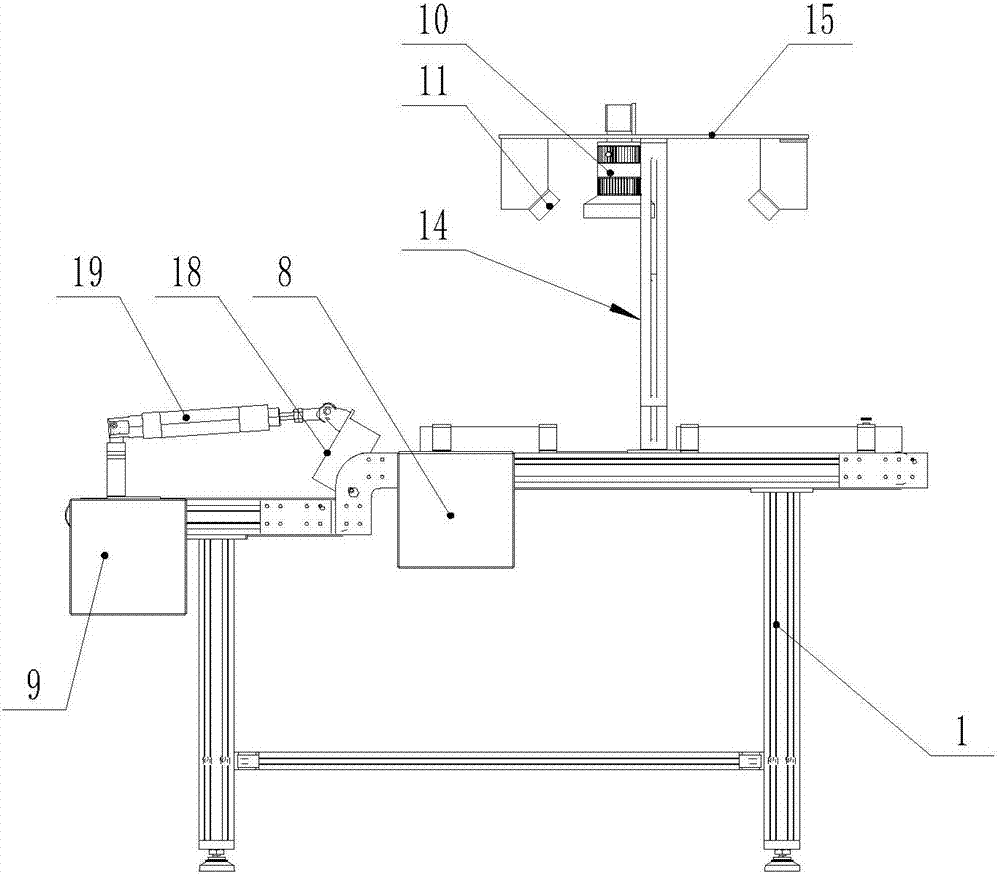

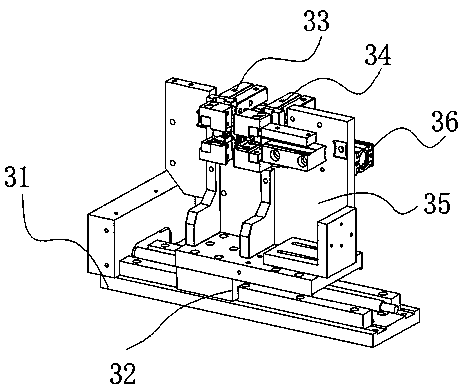

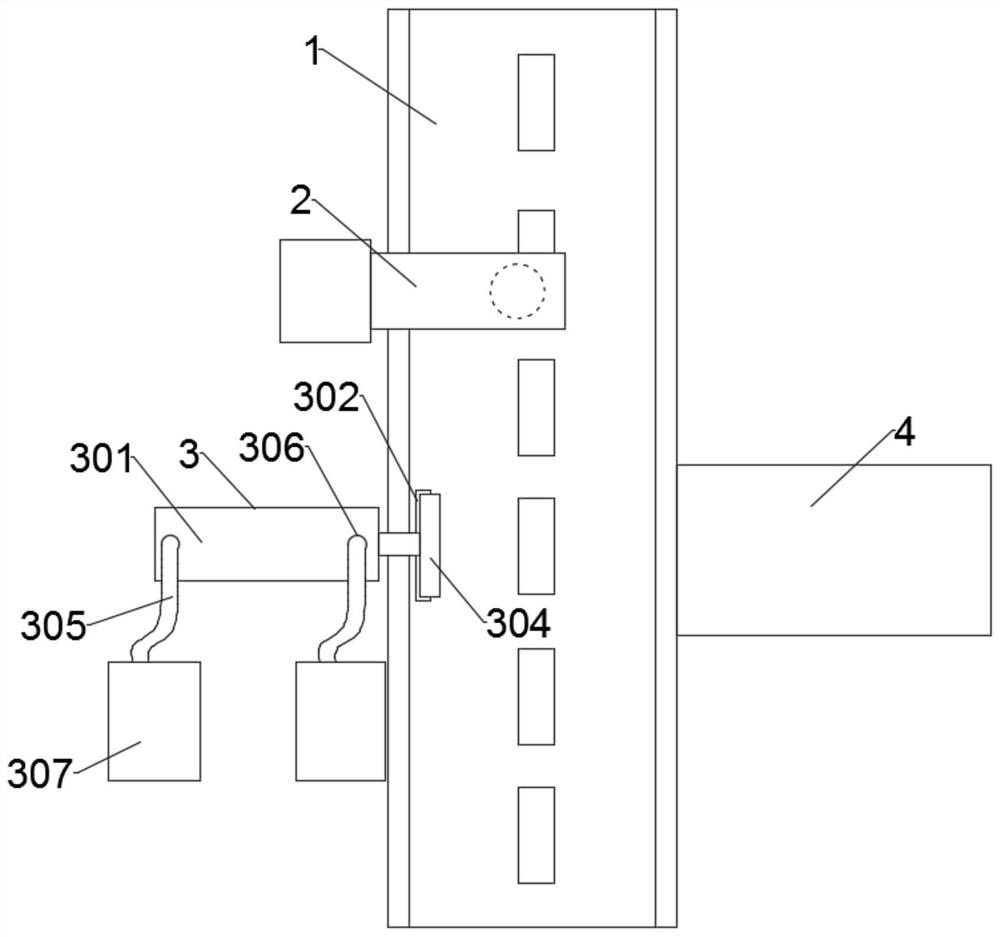

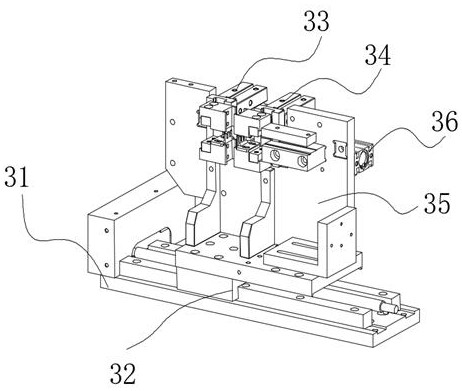

Binding post detection rejection apparatus for air-conditioning compressor

InactiveCN105403153AQuick checkFast detection and rejectionUsing optical meansSortingEngineeringAir conditioning

The invention discloses a binding post detection rejection apparatus for an air-conditioning compressor. The apparatus is characterized by comprising a frame, the frame is provided with a feeding device, a transmission device, a detection device, a rejection device and a control device, wherein the feeding device and the detection device are successively arranged on the frame from the left to the right, the outlet of the feeding device is connected with the transmission device, the transmission device comprises a plurality of clamping manipulators, the detection device comprises an elevating frame and a detection tool, the detection tool comprises a block body, the block body is provided with detection inserting holes, the detection inserting holes are respectively corresponding to binding posts in terms of position and dimension, and the rejection device comprises a rejection slideway and a rejection collection part. According to the invention, the binding post detection rejection apparatus for the air-conditioning compressor, through arrangement of the feeding device, the transmission device, the detection device and the control device, can rapidly detect the binding posts, thereby saving the time and also improving the detection efficiency.

Owner:SUZHOU YUANSHUO PRECISION MOLD

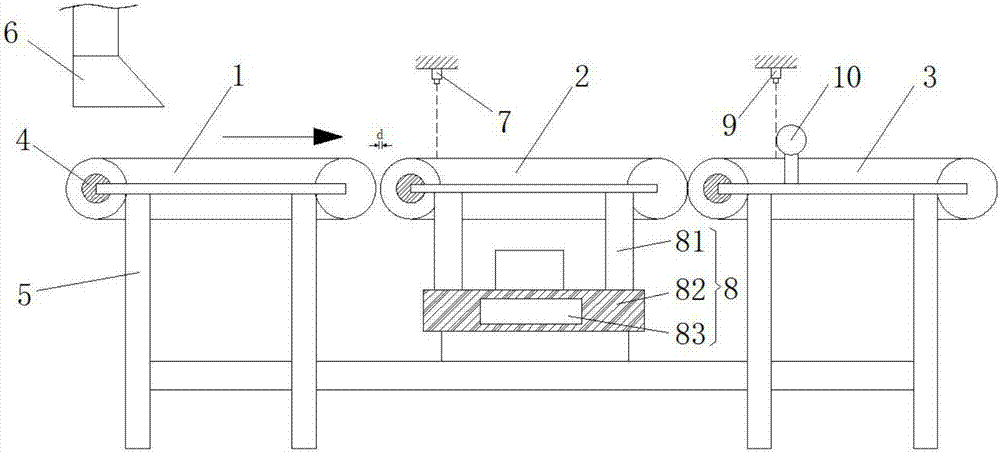

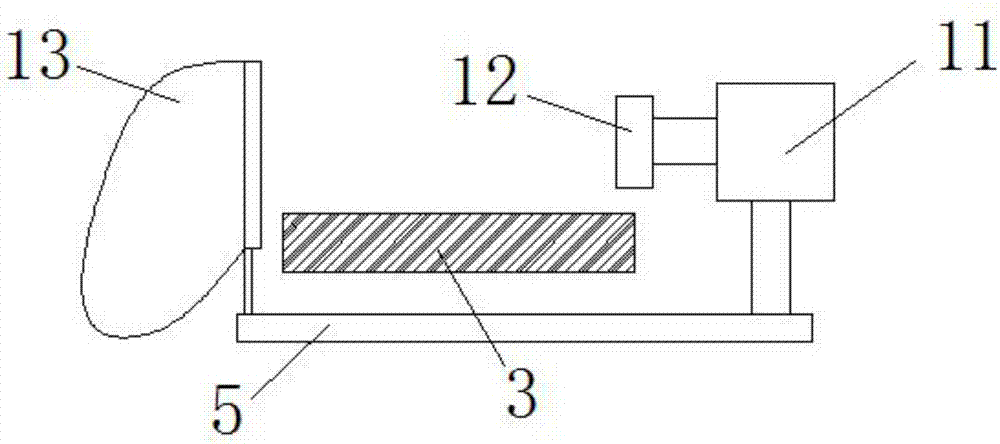

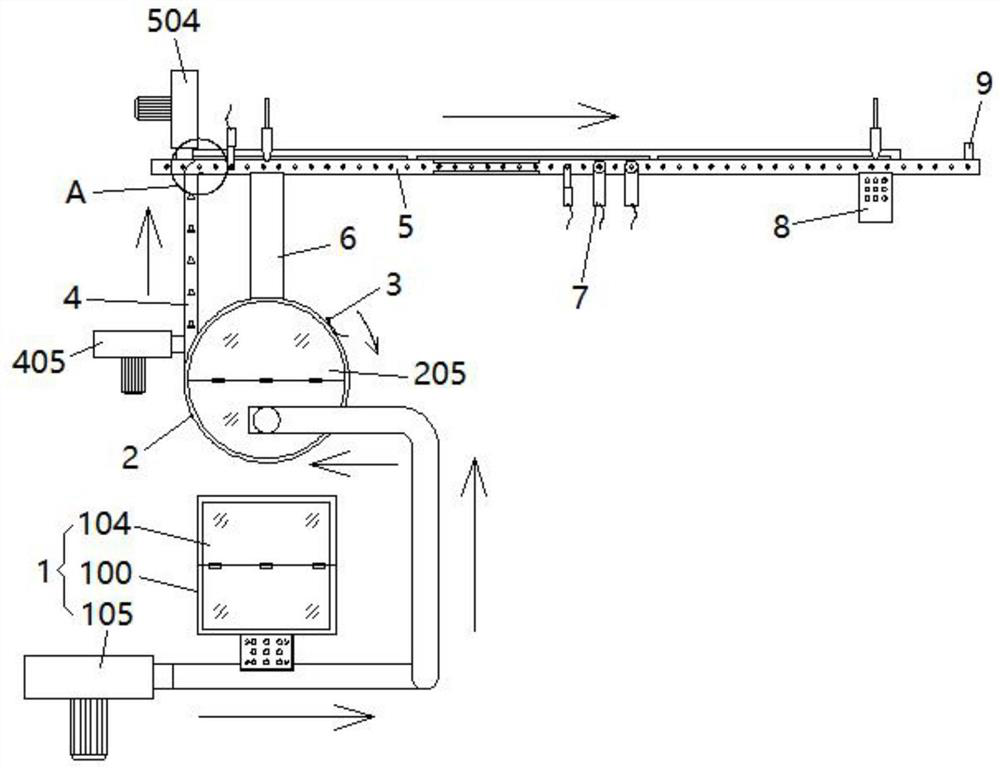

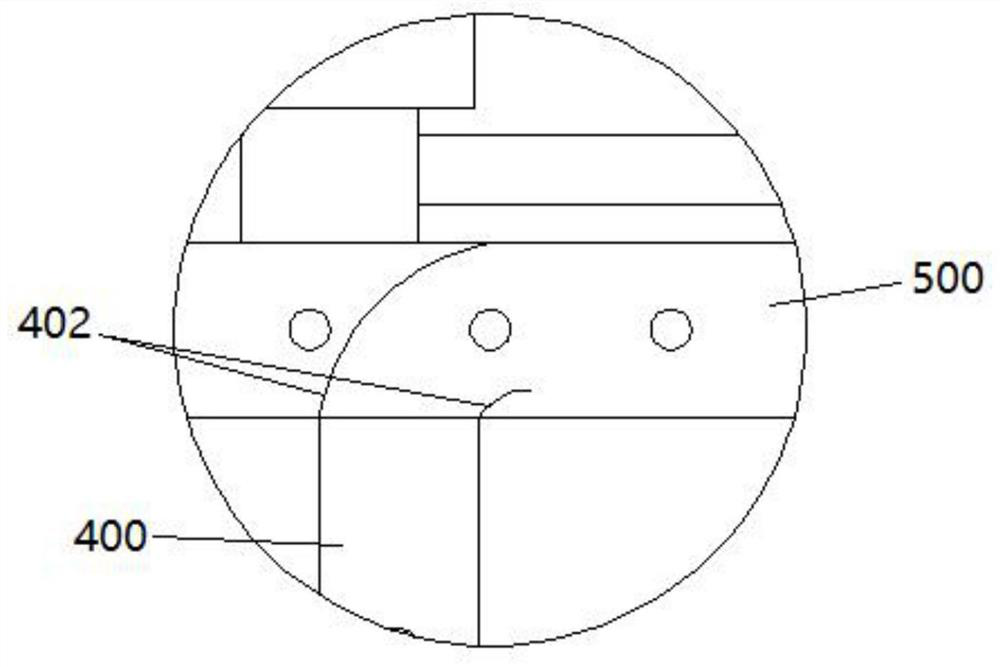

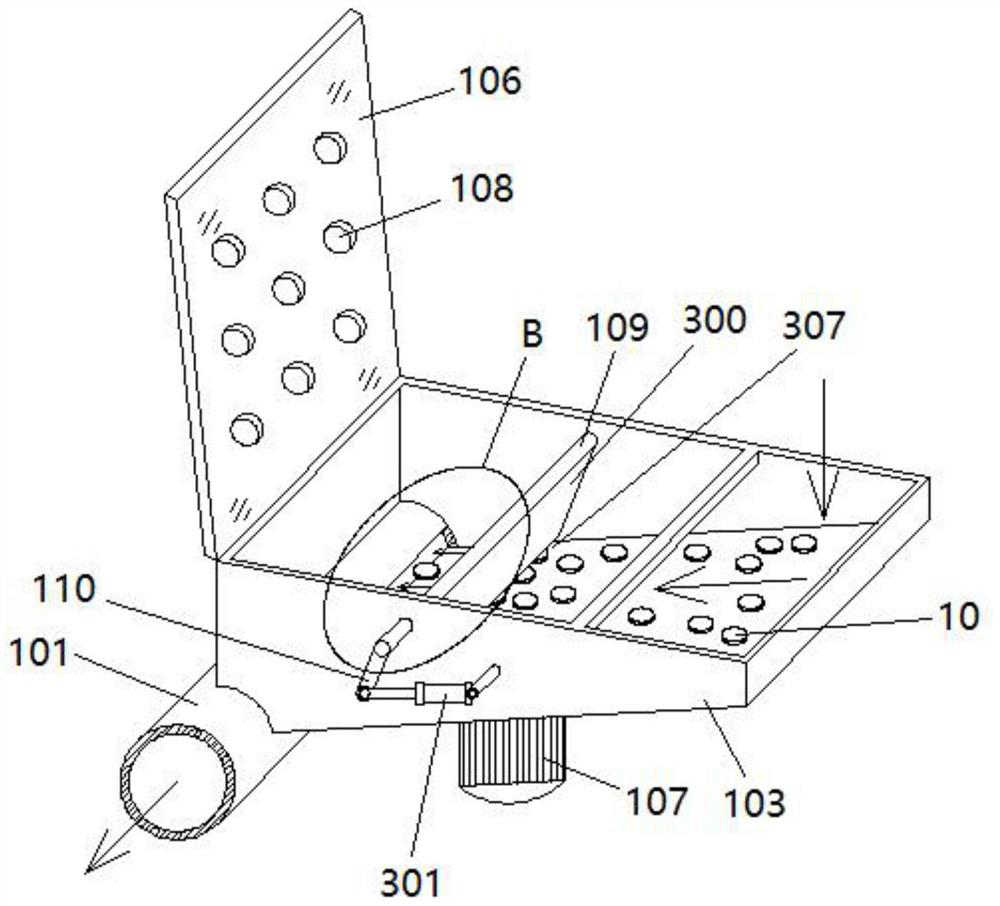

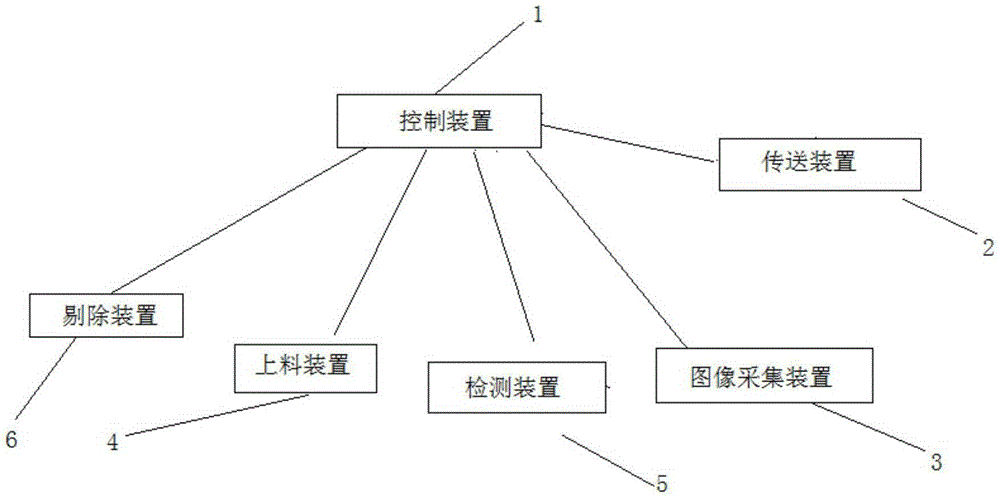

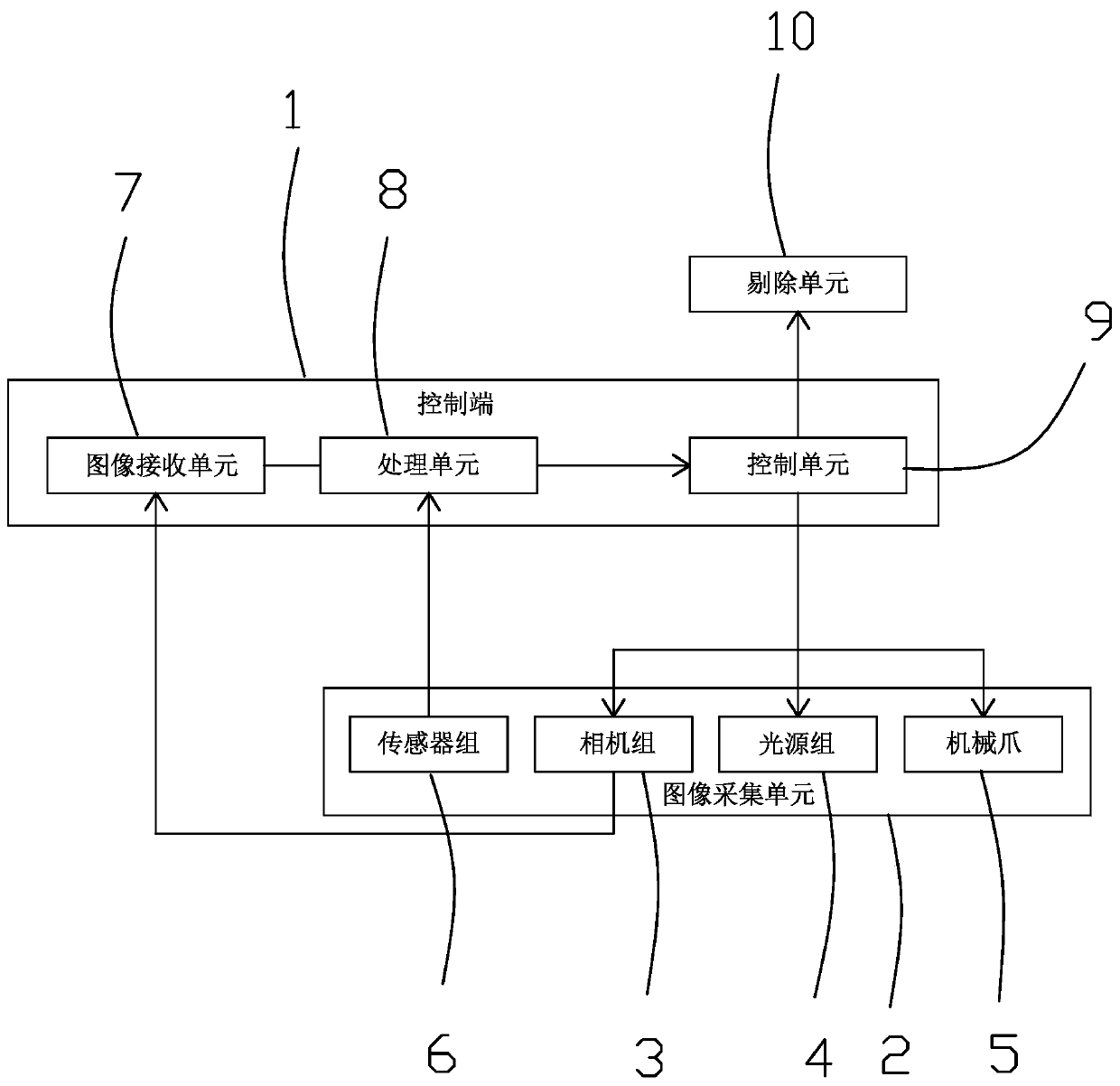

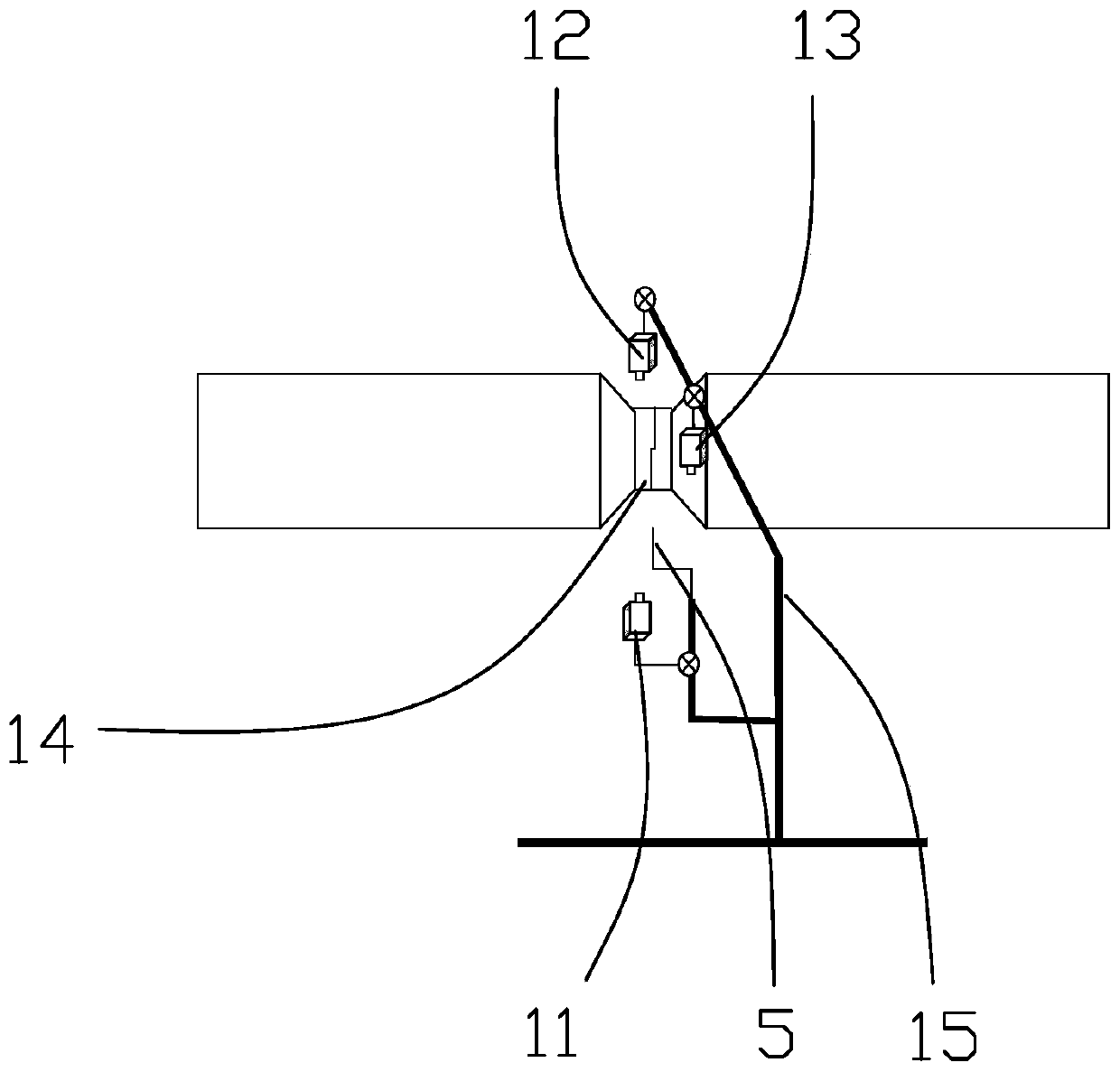

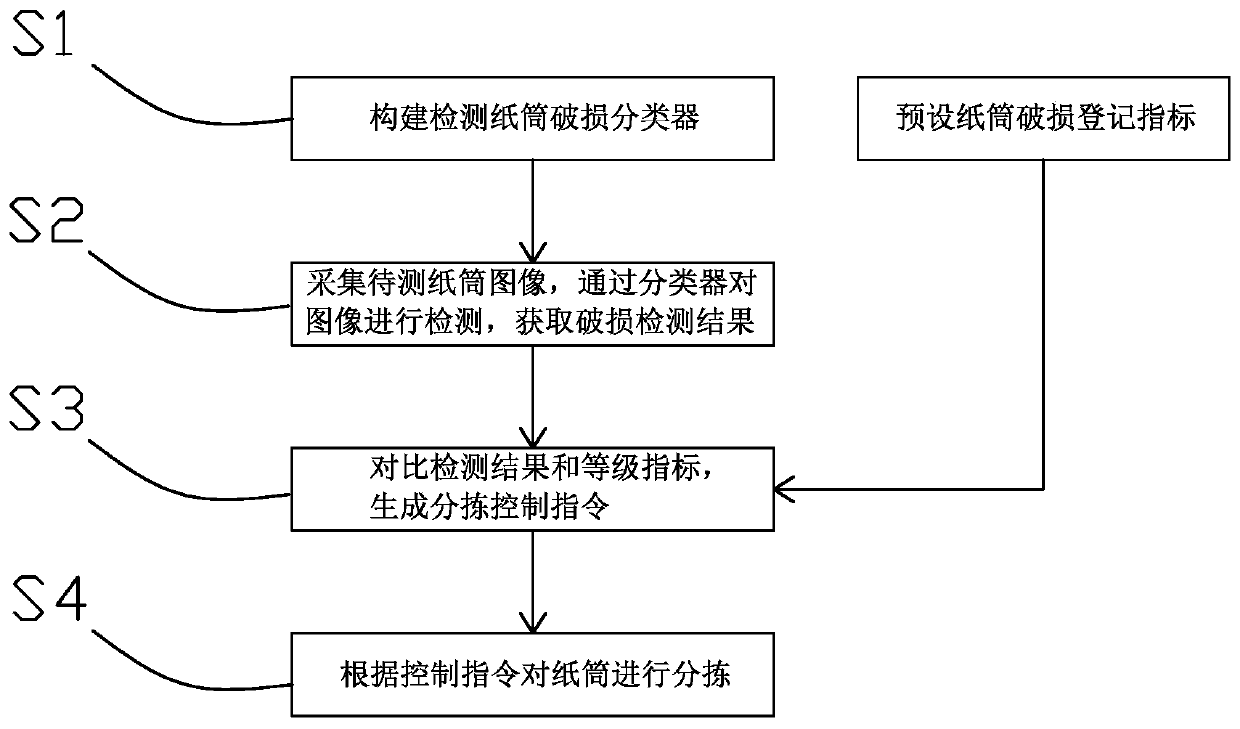

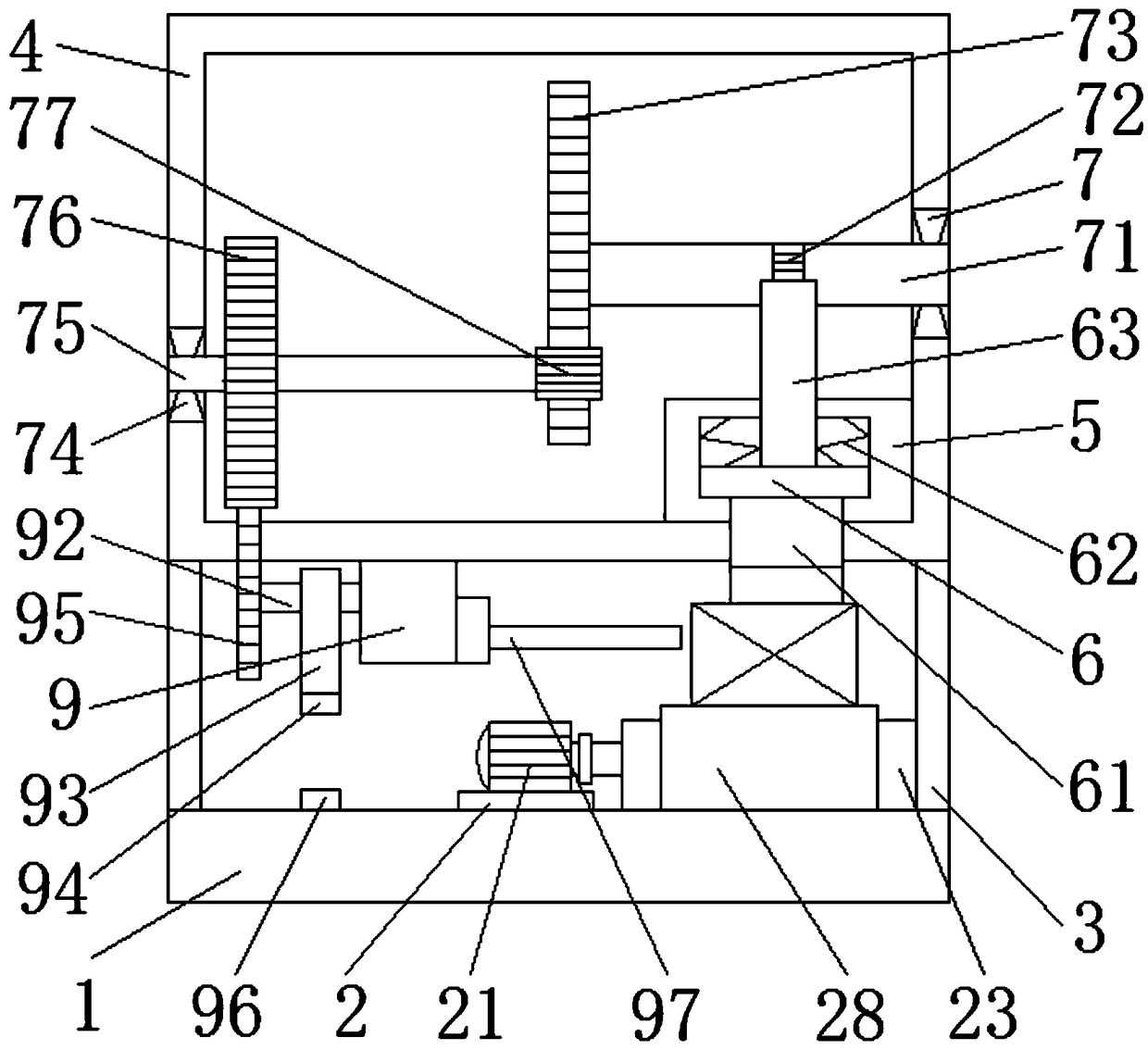

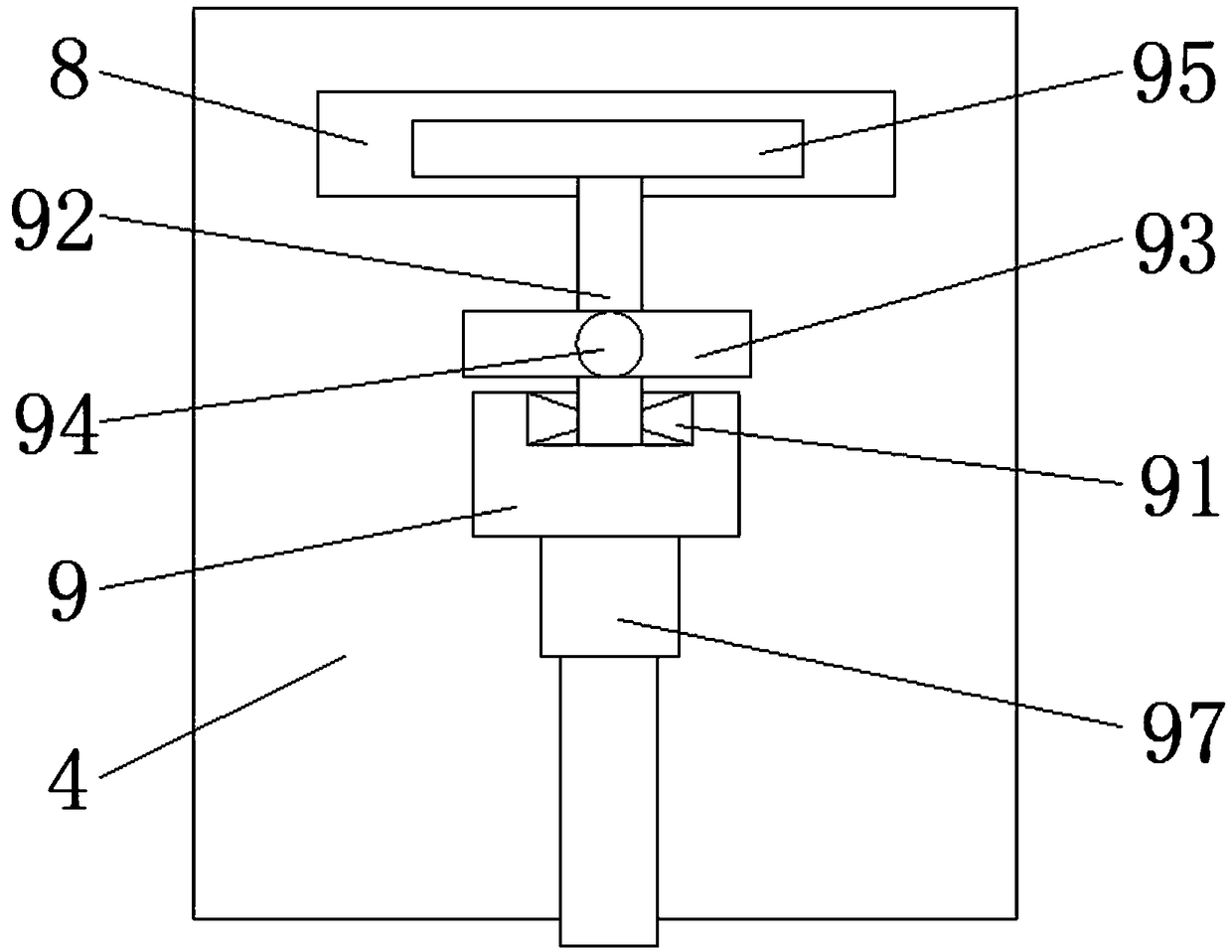

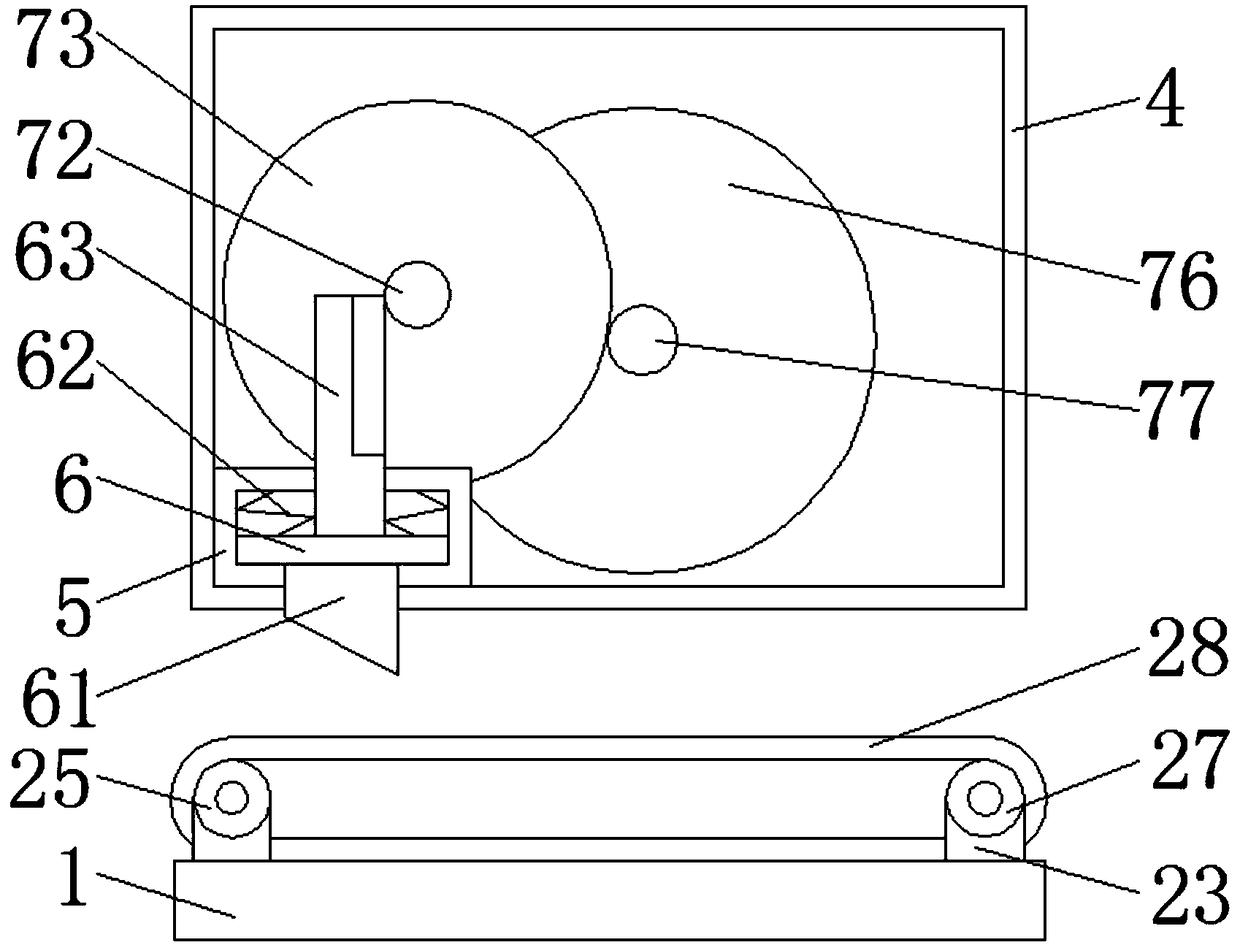

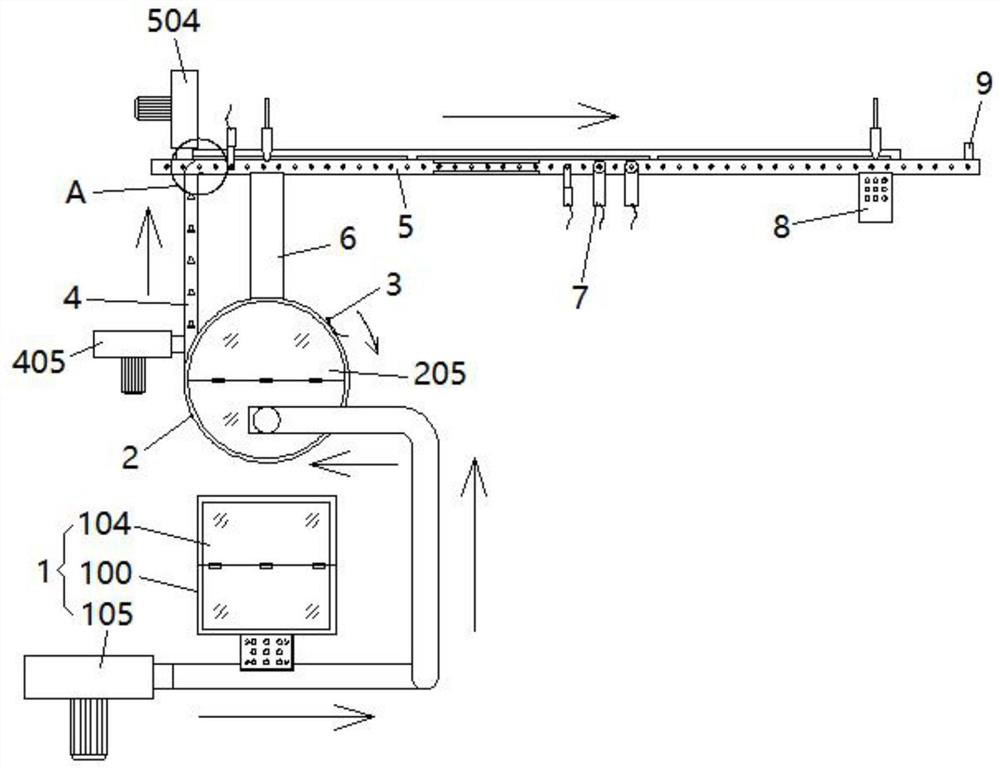

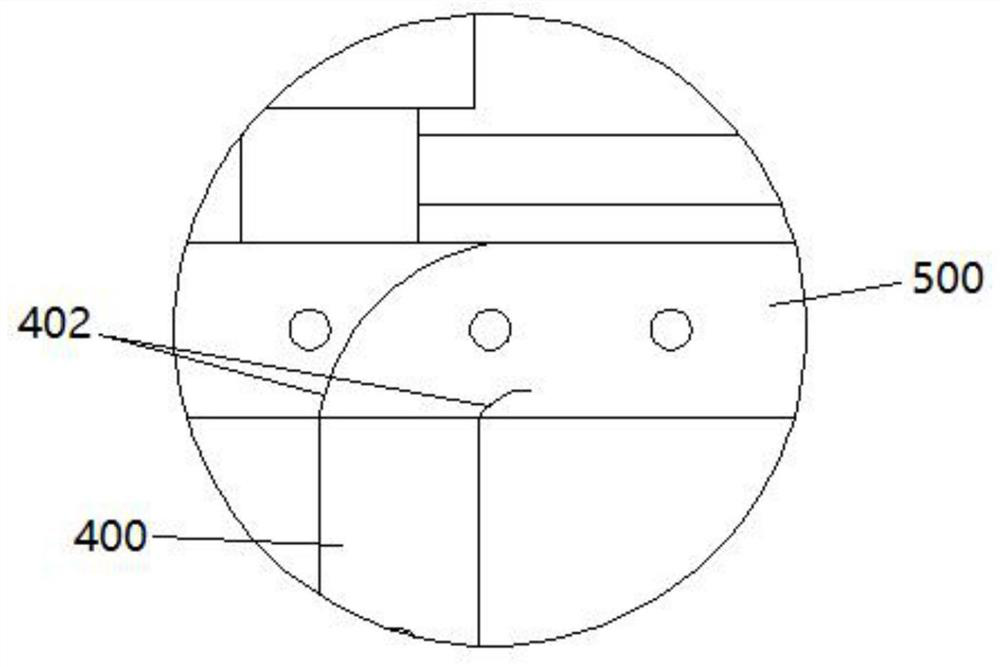

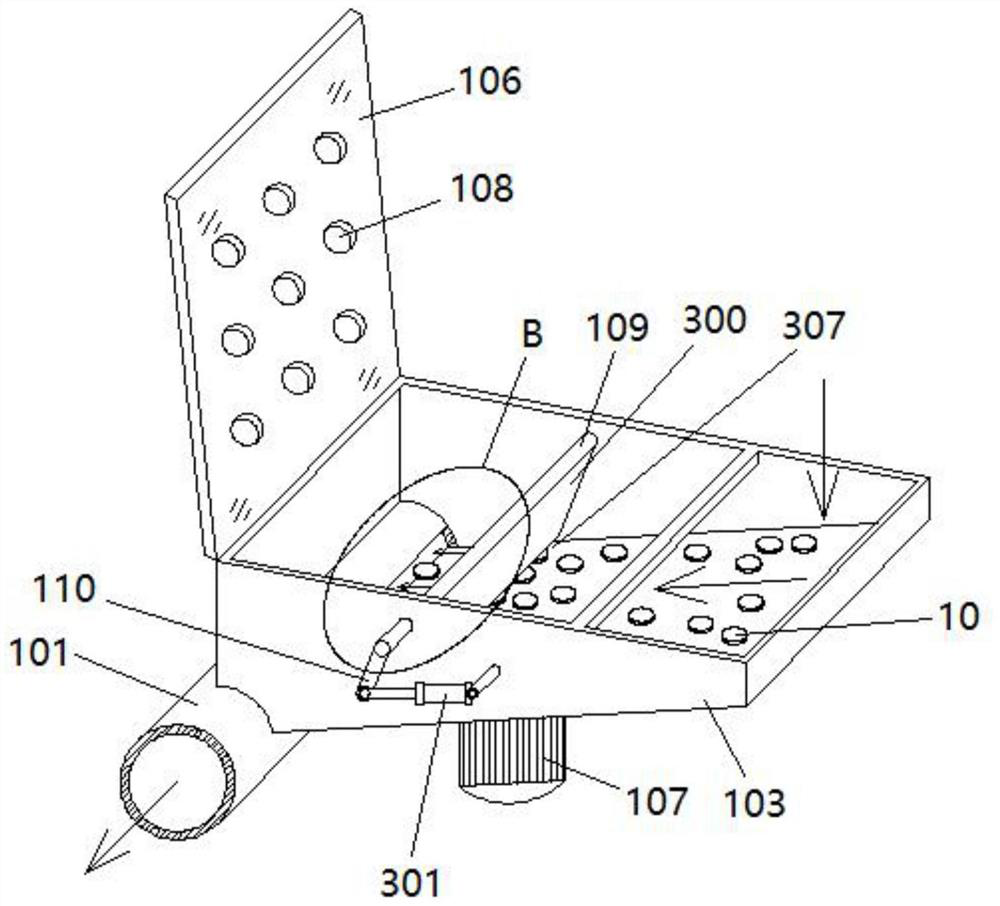

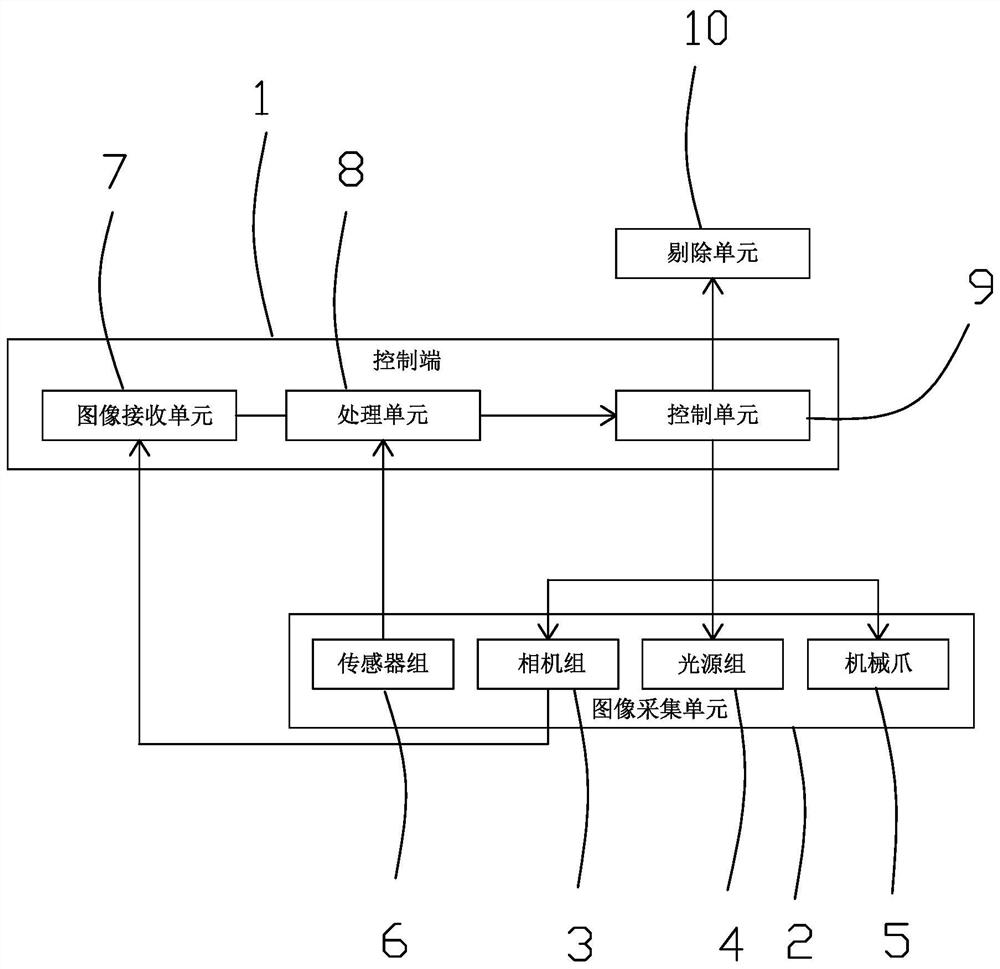

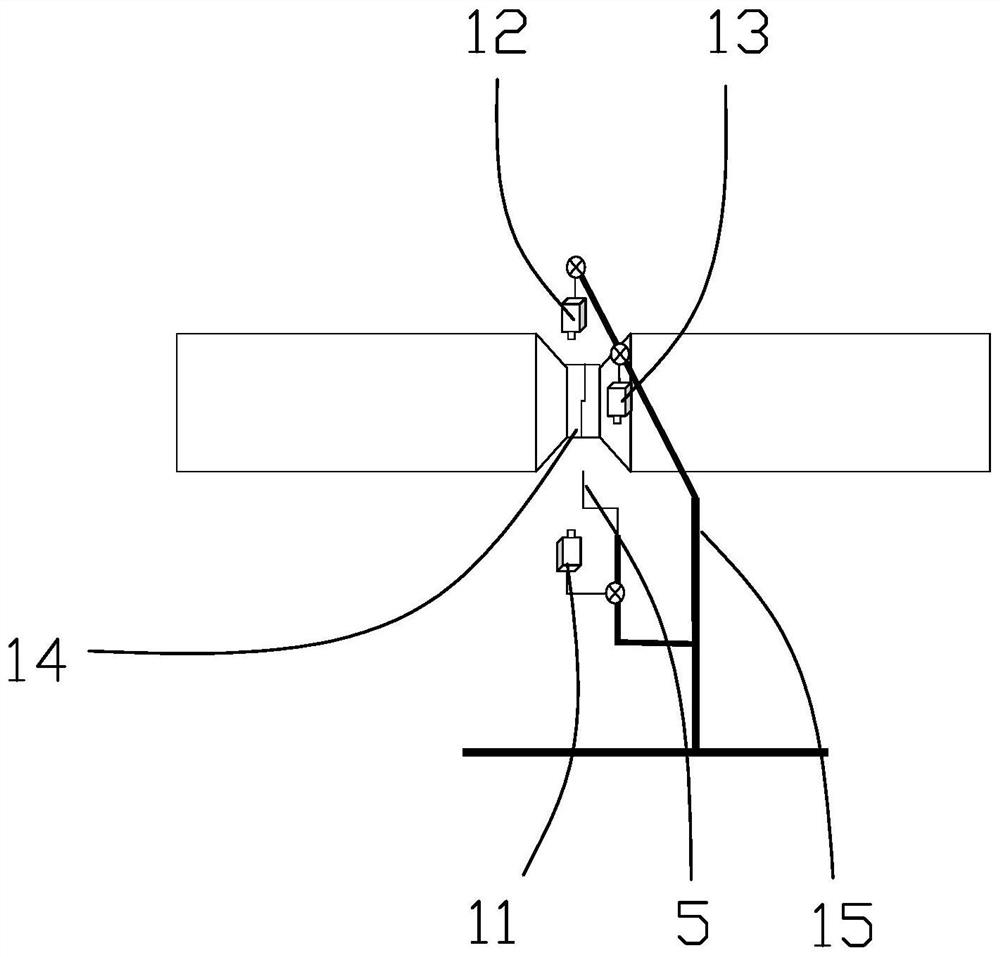

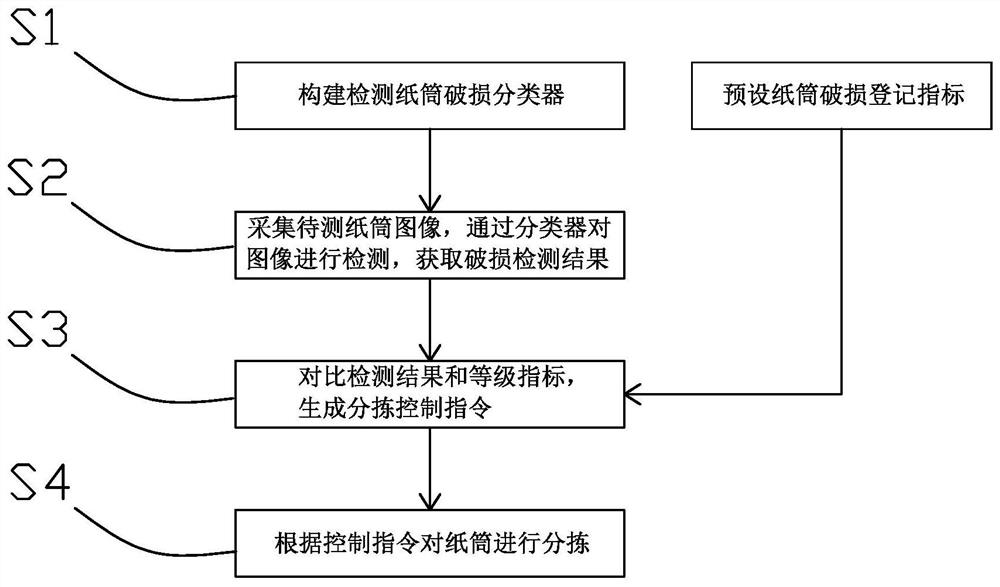

Chemical fiber filament spindle paper tube damage online detecting device and method

ActiveCN110813795ADoes not affect normal productionRealize online automatic detectionMaterial analysis by optical meansSortingComputer hardwareFiber

The invention discloses a chemical fiber filament spindle paper tube damage online detecting device and method. The device comprises a transmitting unit, an image acquisition unit, a control terminal,a removing unit and a sorting unit, wherein the transmitting unit is used for conveying paper tubes; the removing unit sorts the paper tubes on the detecting area of the transmitting unit; the imageacquisition unit is used for carrying out image acquisition on the paper tubes; the control terminal is provided with a classifier for detecting damage of the paper tube; the control terminal receivesthe image information of the image acquisition unit; and the classifier detects the image information, outputs the detecting result, compares the detecting result with the set class index, and sendsa control command to the removing unit according to the comparing result to sort the paper tubes. The device does not affect normal production of paper tubes and filament spindles, realizes online automatic detection of damage of the paper tubes, and removes the damaged paper tubes timely, accurately and rapidly through unified coordination of the transmitting unit, the image acquisition unit andthe removing unit.

Owner:杭州慧知连科技有限公司

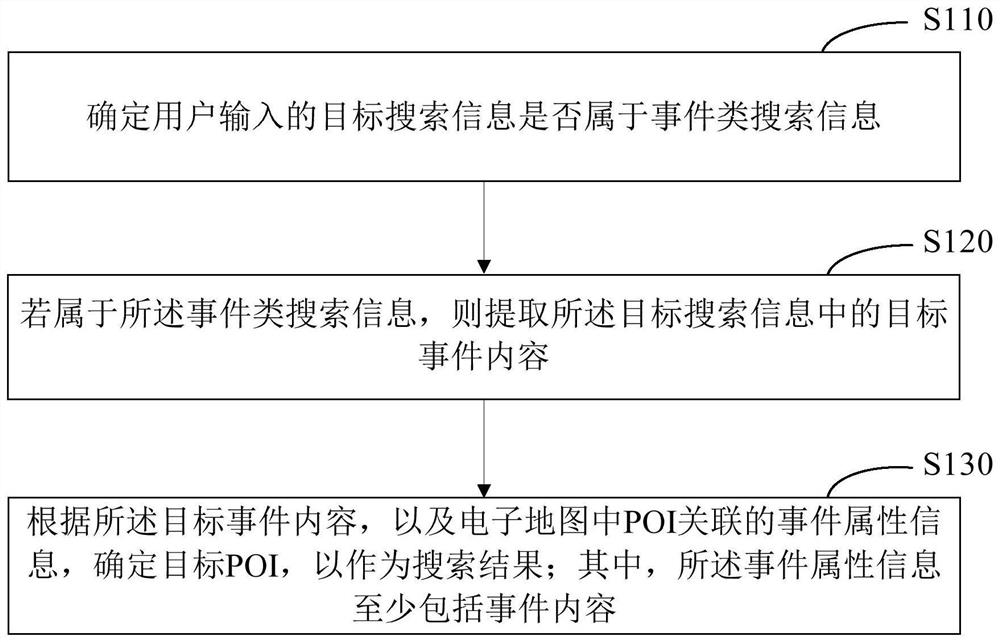

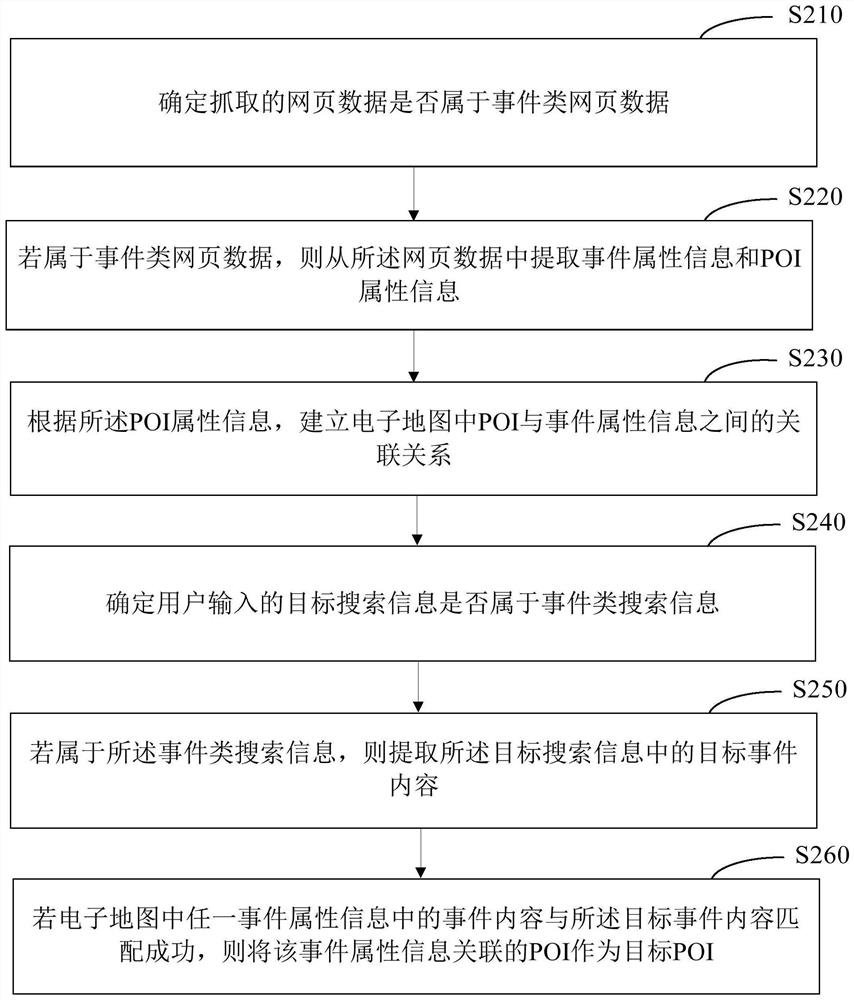

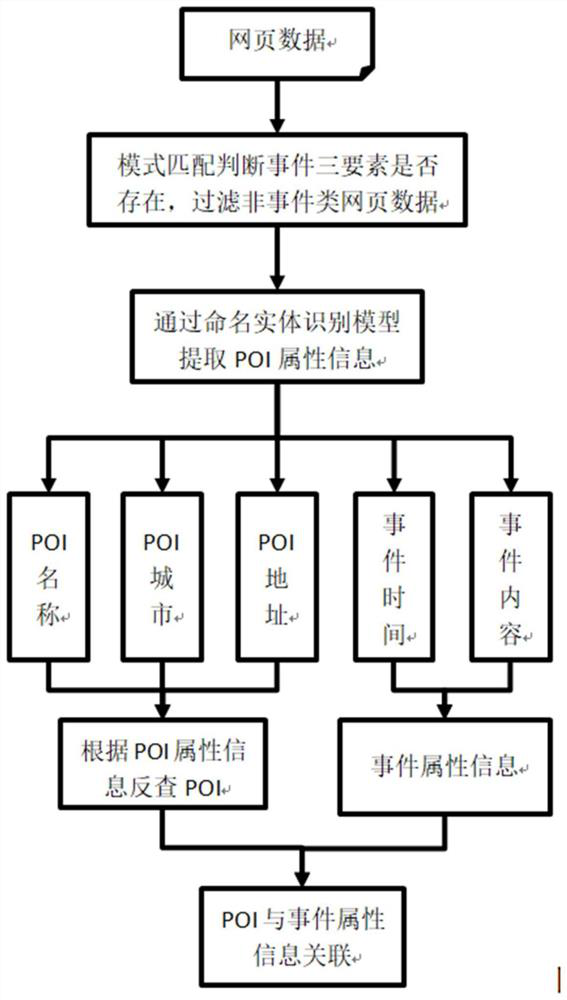

Electronic map searching method and device, equipment and medium

InactiveCN113094600AEliminate associationsAffect the experienceWeb data indexingNatural language data processingEngineeringData mining

The invention discloses an electronic map searching method and device, equipment and a medium, and relates to the technical field of electronic maps. According to the specific implementation scheme, the method includes determining whether target search information input by a user belongs to event type search information or not; if the target search information belongs to the event type search information, extracting target event content in the target search information; determining a target POI as a search result according to the target event content and event attribute information associated with the POI in an electronic map, wherein the event attribute information at least comprises event content. According to the embodiment of the invention, the POI service is provided for the event type search information, so that the search mode of the electronic map is enriched.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

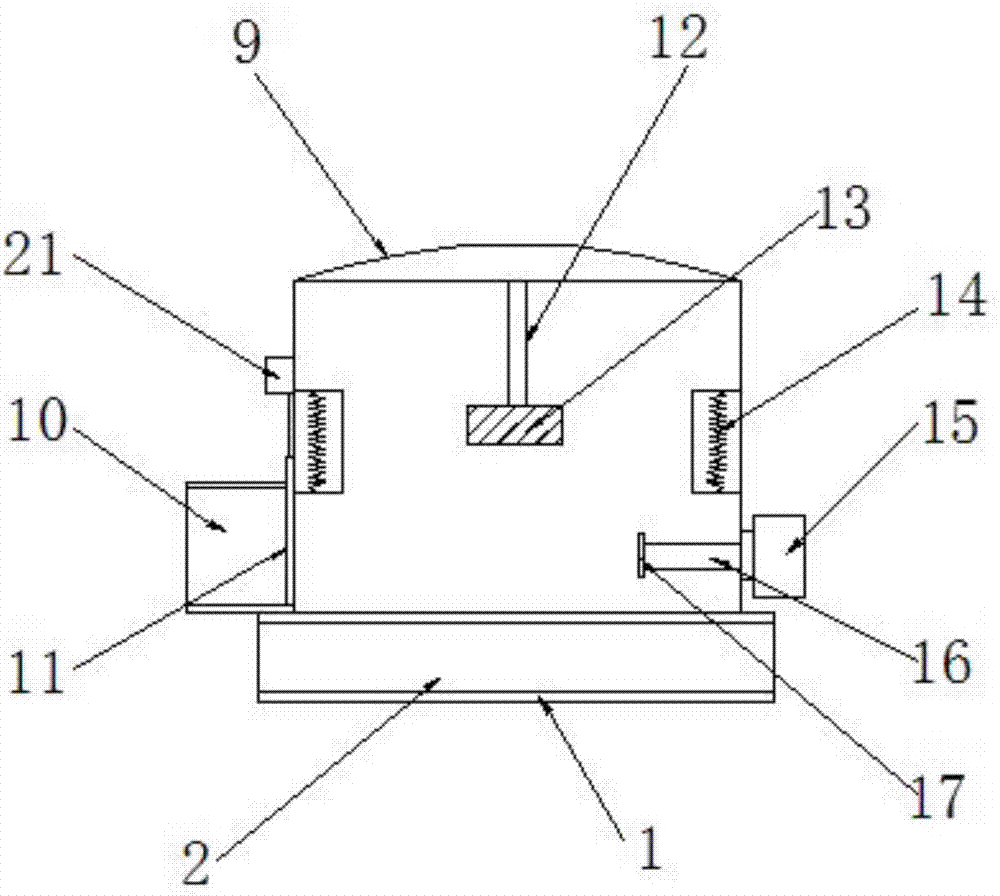

Comprehensive capsule detection device

The invention discloses a comprehensive capsule detection device. The device comprises a machine frame, a storage mechanism, a feeding mechanism, a conveying mechanism, a circumferential detection device, an end detection device and a removing mechanism; the storage mechanism is arranged on the machine frame, a plurality of first falling grooves are formed in the lower portion of the storage mechanism, a plurality of third falling grooves are formed in the feeding mechanism, a plurality of supporting grooves are formed in the conveying mechanism, a stirring plate is arranged below the supporting grooves, the stirring plate is movably arranged in the conveying mechanism, a plurality of first detection cameras are installed on the circumferential detection device, a plurality of second detection cameras are symmetrically mounted on the end detection device, a plurality of discharging channels are arranged on the removing mechanism, and removing grooves are formed in the discharging channels. According to the device, feeding is carried out by the feeding mechanism, the circumferential detection device and the end detection device can carry out image detection on the circumferential direction and the two ends of a capsule, so that the unqualified capsules are removed in time, and the quality of the capsules is guaranteed.

Owner:王麒凯

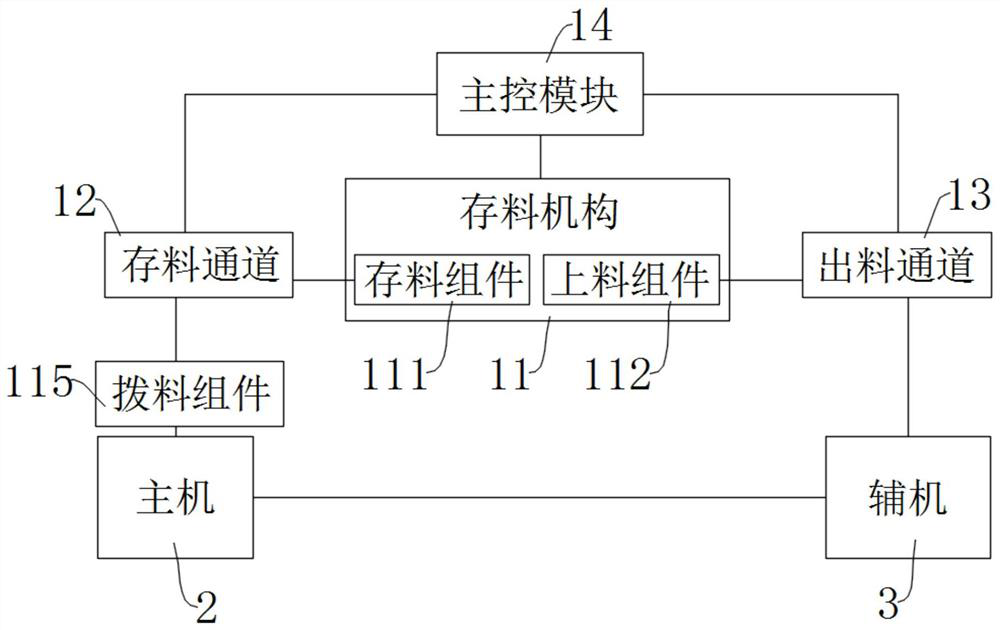

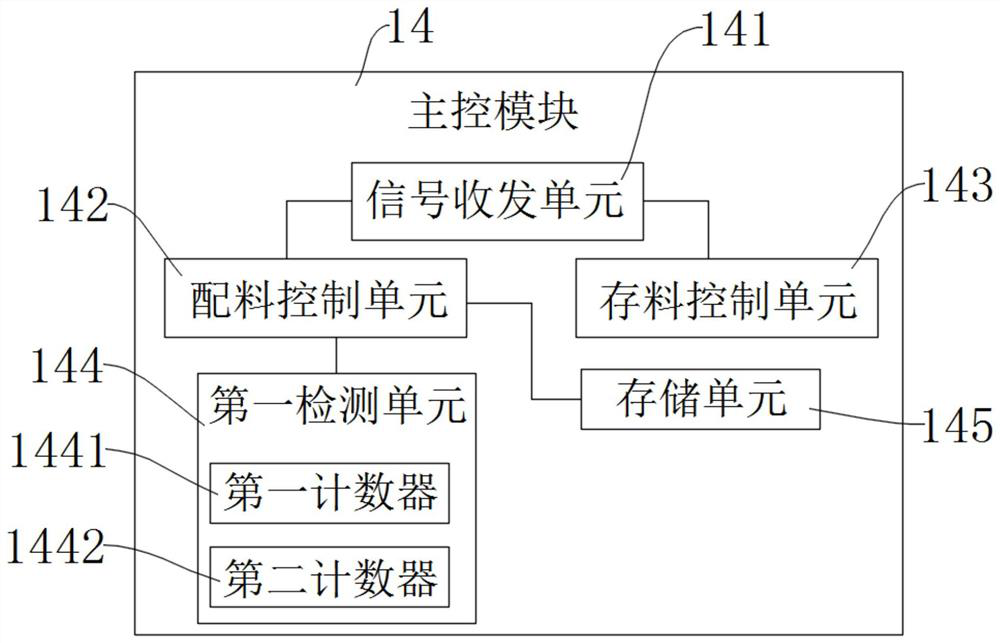

Emergency caching system applied to small cigarette packet processing

ActiveCN113145486AReasonable ingredientsImprove processing efficiencySortingPacket processingEngineering

The invention provides an emergency caching system applied to small cigarette packet processing. The emergency caching system comprises a main control module, a material storage channel, a discharging channel and a material storage mechanism, wherein the main control module is electrically connected with the material storage channel, the discharging channel and the material storage mechanism, one end of the material storage channel and one end of the discharging channel are connected with the material storage mechanism, the end, away from the material storage mechanism, of the material storage channel is connected with the main machine, and the end, away from the material storage mechanism, of the discharging channel is connected with an auxiliary machine. When the auxiliary machine fails, small packets of cigarettes conveyed by the main machine can be cached and reasonably distributed, and meanwhile, the quality of the distributed small packets of cigarettes can be improved, so that the problems that in the existing small cigarette packet processing process, the efficiency is low, material conveying is not reasonable enough, and the batching quality cannot be guaranteed are solved.

Owner:南京专注智能科技股份有限公司

Automatic metal removing mechanism for Chinese herbal medicine screening machine

The invention discloses an automatic metal removing mechanism of a traditional Chinese medicinal material screening machine, which comprises a conveyor belt, a rotating shaft, a motor, a pillar, a first detection mechanism, a coil, an alarm, an alarm light, a rejecting mechanism, a rejecting box, a baffle, a pole, A distance sensor, a second detection mechanism, a cylinder, a push rod, a rejecting plate, a main drive wheel, an auxiliary drive wheel, a bracket and an electric push rod. The metal automatic removal mechanism of the Chinese medicinal material screening machine of the present invention has changed the traditional detection and removal method, adopts the conveyor belt to convey the detection and removal, and adjusts the rotation speed of the conveyor belt through the motor, which can make the Chinese medicinal materials flow smoothly and improve the accuracy of the detection during the metal detection process. The rate is high, and the unqualified products are alarmed in time; the rejecting mechanism is equipped with a distance sensor and a rejecting confirmer, which can judge the position of unqualified products in Chinese herbal medicines and remove them in time, and ensure the rejecting rate and the pass rate of the product. Good economic and production benefits, suitable for popularization and use.

Owner:HUBEI HUMANWELL CHENGTIAN PHARMA

New energy automobile battery recycling, detection and reutilization device

PendingCN109099825ARemoval in timeReduce damage by corrosionSortingMechanical solid deformation measurementsNew energyElectrical battery

The invention discloses a new energy automobile battery recycling, detection and reutilization device, which comprises a base, wherein a transmission device is arranged on the upper surface of the base; the transmission device comprises a motor base; the lower surface of the motor base is fixedly connected to the upper surface of the base; the upper surface of the base is fixedly connected to supporting plates; the supporting plates are arranged on the two sides of the motor base; and the upper surfaces of the supporting plates are fixedly connected to a chassis. According to the new energy automobile battery recycling, detection and reutilization device, a detection device is arranged inside a transmission box, and the detection device comprises a limiting block, wherein the surface of the limiting block is in sliding insertion connection with the inner wall of the transmission box; an amplifying device is arranged in the chassis; the amplifying device comprises a first bearing; the outer ring of the first bearing is fixedly connected to the inner wall of the chassis; a through hole is arranged in the lower surface of the chassis; a removing device is arranged on the lower surfaceof the chassis; and the device has the characteristics of timely detecting and removing an expanded battery.

Owner:常州朝旭企业服务有限公司

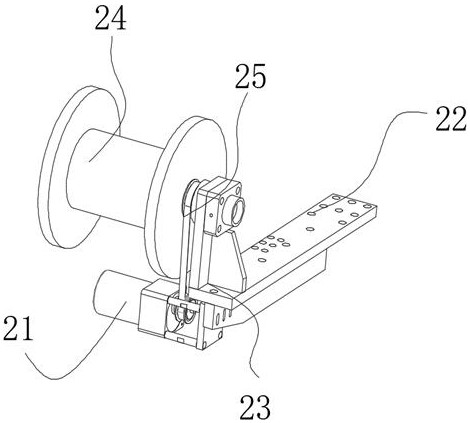

Full-automatic assembling and welding technology for LED lamp beads

ActiveCN111360349AReduce manual operationsImprove assembly quality and efficiencySoldering apparatusPretreated surfacesPhysicsSoldering

The invention discloses a full-automatic assembling and welding technology for LED lamp beads. The assembling technology comprises the steps that 1, lamp band accessories are fed and conveyed; 2, thelamp band accessories are stripped, positioned and separated; 3, LED lamp accessories are fed and conveyed; 4, a manipulator sucks the LED lamp accessories and conveys the LED lamp accessories to a turning mechanism; 5, the manipulator clamps and conveys the turned LED lamps to the lamp installing process; 6, the LED lamp accessories and the lamp band accessories are combined to form combined lampbands; 7, soldering is conducted on the self-combined lamp bands; 8, adhesive dispensing is conducted on the lamp bands obtained after soldering; 9, ultraviolet positioning and curing are conducted on the lamp bands obtained after adhesive dispensing; 10, pay-off tensioning is conducted on the lamp bands obtained after curing and positioning; and 11, winding take-up operation is conducted on theassembled lamp bands. According to the full-automatic assembling and welding technology for the LED lamp beads, the automatic assembling process of the LED lamp bands is achieved, the production efficiency and quality are improved, and the good market application value is achieved.

Owner:JIANGMEN CITY SEC LEE DI PHOTOELECTRIC LIGHTING CO LTD

Method for removing residual materials of cyclone separator by vibration

ActiveCN110052337AImprove separation efficiencyEasy to reuseSievingReversed direction vortexWaste materialLarge particle

The invention discloses a method for removing residual materials of a cyclone separator by vibration. A vibrating screen is additionally arranged behind the cyclone separator, the residual materials of the cyclone separator can be removed, the large particle size materials discharged from the bottom of the separator can be effectively recycled for second time, the large particle size materials aremixed with the small particle size materials, repeated utilization of the small particle size materials are increased, the waste materials deposited at the bottom of the equipment can be removed in time, the separation efficiency of the cyclone separator is improved, dust removal can be timely carried out, the dust removal efficiency is improved, and the energy-saving effect is further realized.

Owner:HUAQIAO UNIVERSITY

A two-dimensional code printing device for gaskets in bottle caps

The invention discloses a two-dimensional code printing device for gaskets in bottle caps, which includes a feeding mechanism, a material sorting mechanism, a linkage mechanism, a first and a second conveying mechanism, a blowback mechanism, a two-dimensional code printing and detection mechanism, Defective product rejecting mechanism and encoder; gaskets are sequentially transported to the second conveying mechanism by the feeding mechanism, material sorting mechanism and the first conveying mechanism, and the blowback mechanism blows back the gaskets whose spacing does not meet the requirements to the material sorting mechanism. The two-dimensional code printing and testing mechanism prints the two-dimensional code on the surface of the gasket, and detects the printed gasket, and cooperates with the defective product rejection mechanism to remove unprinted products and defective products. The invention can realize automatic and assembly line production, can print the two-dimensional code storing product information on the surface of the gasket, and can achieve information traceability, marketing promotion and other effects, and the bottle cap thus formed has a built-in two-dimensional code It has better anti-counterfeiting effect, and has the characteristics of high production efficiency, high authenticity rate, short production cycle and low cost.

Owner:ANHUI BAISHIJIA PACKING CO LTD

A real-time inspection method for capsules using double detection

ActiveCN105241890BImprove drug qualityRemoval in timeOptically investigating flaws/contaminationSortingReal time validationEngineering

The invention relates to a capsule real-time inspection method with double detection, which comprises the following steps: 1) providing a capsule real-time test platform with double detection, which includes a near-infrared detection mechanism, a visible light detection mechanism and a main controller, wherein the near-infrared detection mechanism and the visible light detection mechanism respectively perform defect detection to every capsule and the main controller is respectively connected to the near-infrared detection mechanism and the visible light detection mechanism for determining a capsule rejection strategy according to a defect detection result from the near-infrared detection mechanism and the visible light detection mechanism; and 2) performing inspection with the test platform. According to the method, there are two detection methods are available to detect the capsules, thereby improving reliability of capsule test.

Owner:NANNING FRESH LIFE BIOTECH

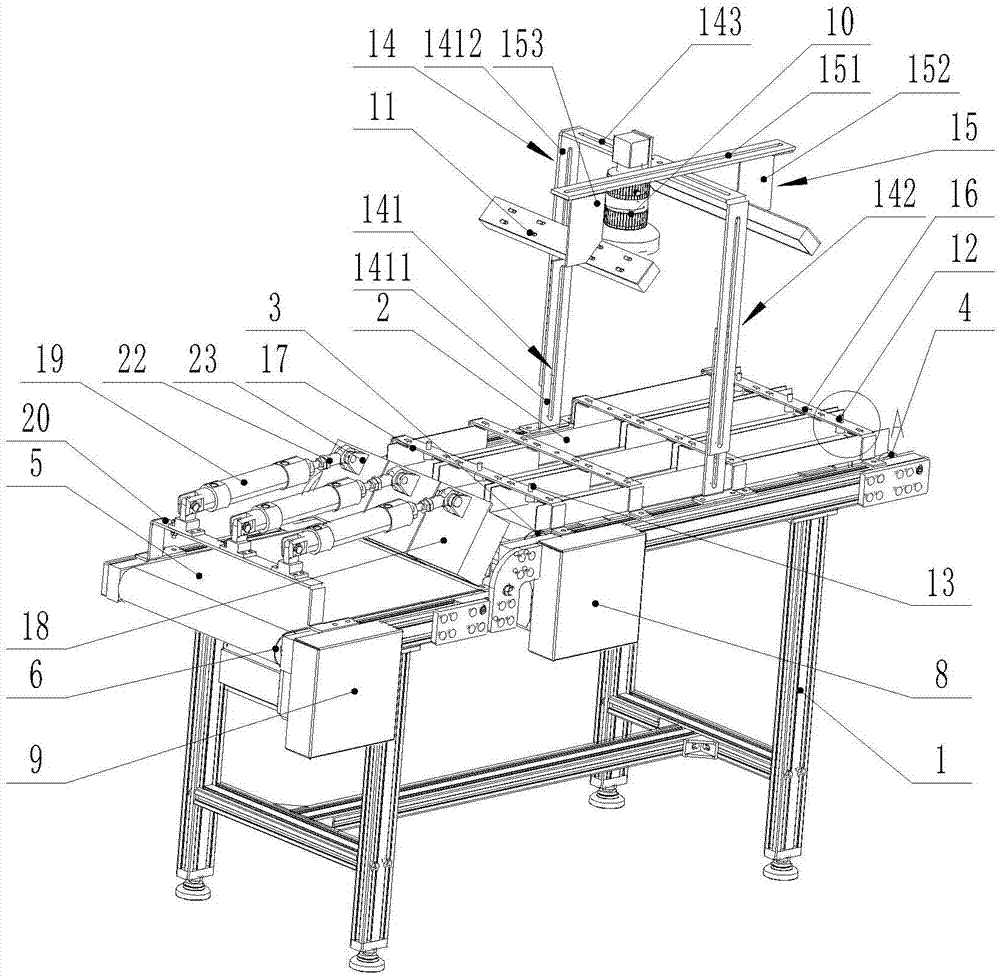

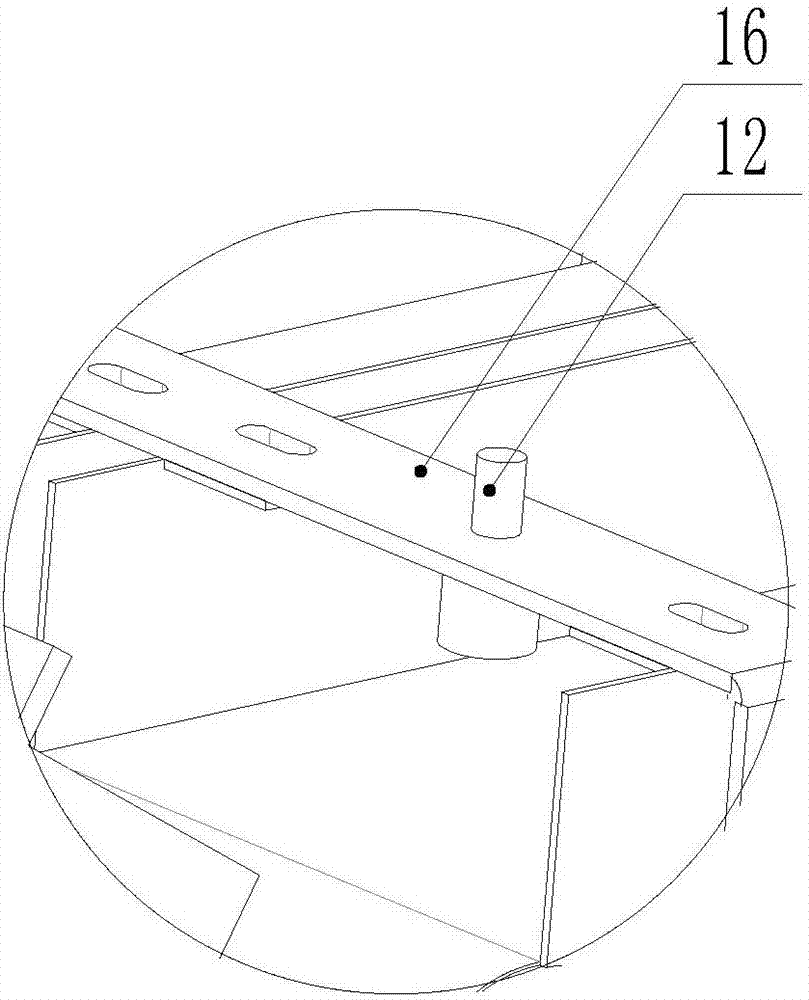

A visual detection-based rejection device and its implementation method

ActiveCN110712810BSolve the detection speed is slowImprove detection accuracyPackaging automatic controlProduction lineControl engineering

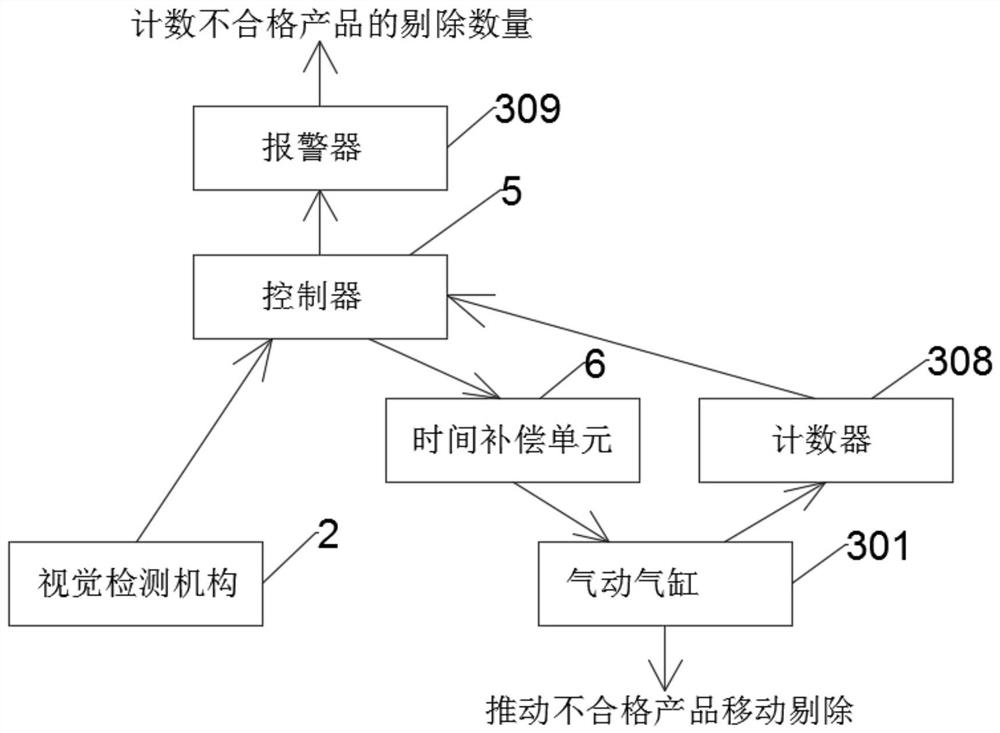

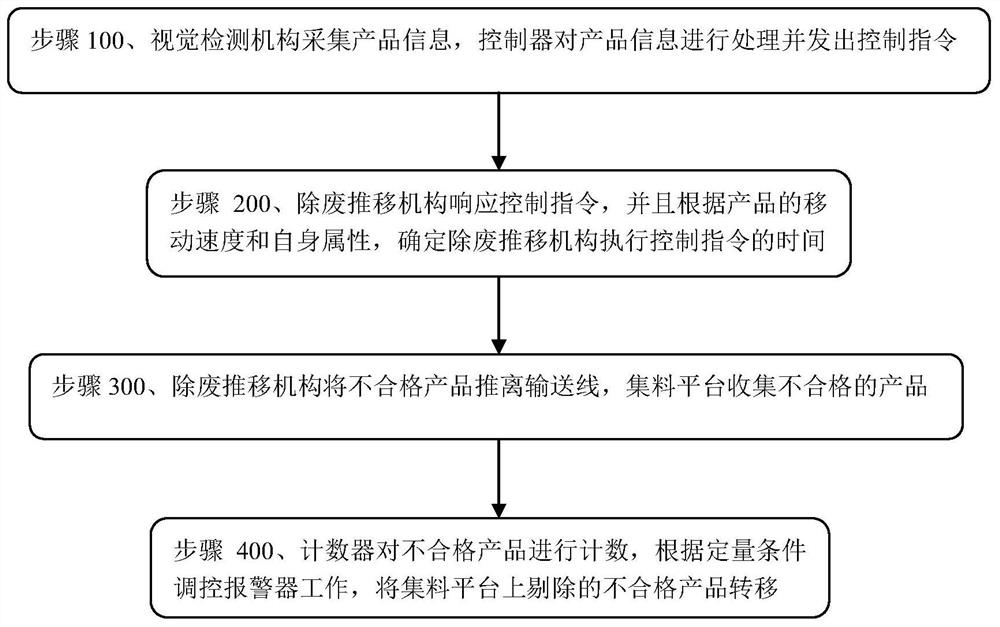

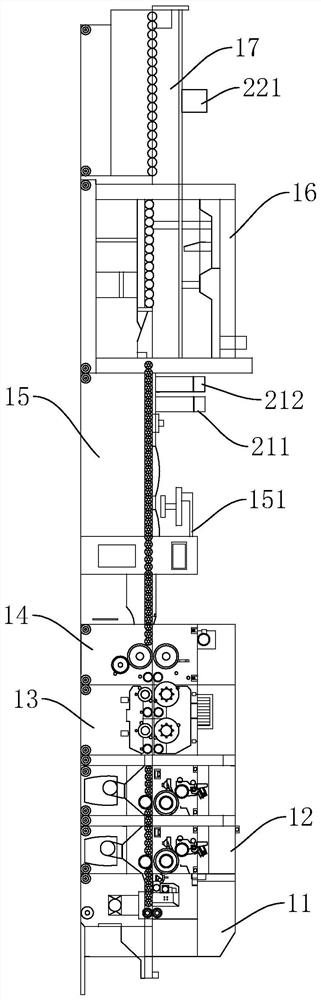

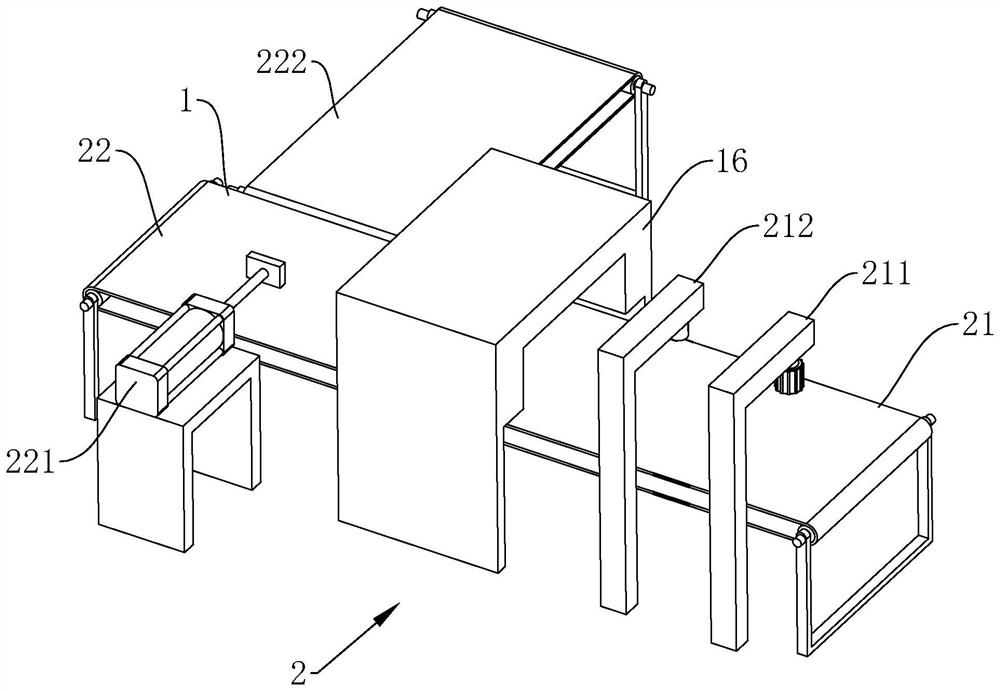

The embodiment of the present invention discloses a visual detection-based rejecting device and its implementation method, including a conveying line for power transmission of gift boxes, and a visual detection mechanism arranged on the conveying line. The two sides of the conveying line are respectively behind the visual detection mechanism There is a waste removal and pushing mechanism and a collecting platform. The visual detection mechanism is connected to the controller, and the visual detection mechanism is connected to the input end of the controller. The controller regulates the work of the waste removal and pushing mechanism according to the detection results of the visual detection mechanism. The organization pushes the unqualified products on the conveyor line to the collection platform for recycling; this solution effectively improves the detection speed and accuracy of the production line, greatly improves the output and quality, reduces labor costs, and prevents misjudgments caused by human eye fatigue , Improve production speed and packaging quality.

Owner:SHAN DONG DONG E E JIAO

A corrugated box printing and bonding production line with high-speed coding function

ActiveCN109334102BRemoval in timeIncrease productivityBox making operationsPaper-makingProduction lineError reporting

The invention discloses a corrugated case printing-adhering production line with a high-speed code-spraying function, belongs to the field of corrugated case production, and aims to provide the corrugated case production line capable of on-line rejecting defective code-spraying products, saving manpower and material resources, and improving the production efficiency. The invention has the technical scheme that the corrugated case printing-adhering production line with the high-speed code-spraying function comprises a tank feeding conveyor belt, a paper feeding part, a printing part, a slottingand line pressing part, a die cutting part, a folding and case-adhering part, a stacking part and a counting and bundling part, wherein the paper feeding part, the printing part, the slotting and line pressing part, the die cutting part, the folding and case-adhering part, the stacking part and the counting and bundling part are sequentially arranged along the conveying direction of the tank feeding conveyor belt; a code spraying mechanism is arranged on the folding and case-adhering part; a defective product rejection part is further arranged additionally and comprises a detection platform and a rejection platform; the detection platform is located between the folding and case-adhering part and the stacking part; a detection device for detecting abnormal codes is arranged on the detection platform; and after the rejection platform is arranged on the counting and bundling part along the conveying direction of the tank feeding conveyor belt, a rejection device is arranged on the rejection platform, so that when the detection device sends out an error reporting command, the rejection device receives the command and rejects the defective products.

Owner:合肥丹盛包装有限公司

A device and method for on-line detection of damage to a chemical fiber spindle paper tube

ActiveCN110813795BDoes not affect normal productionRealize online automatic detectionMaterial analysis by optical meansSortingGraphicsFiber

The invention discloses an on-line detection device and method for damage of a chemical fiber silk ingot paper tube. It includes a transmission unit, an image acquisition unit, a control terminal, a rejecting unit and a sorting unit. The transmission unit is used to convey the paper tubes, the rejecting unit sorts the paper tubes in the detection area on the transmission unit, and the image acquisition unit sorts the paper tubes Image acquisition, the control end has a classifier for detecting damaged paper tubes, the control end receives the image information of the graphic acquisition unit, the image information is detected by the classifier and outputs the detection result, the detection result is compared with the set grade index, and according to the comparison result to the The rejecting unit issues a control command to sort the paper tubes. The invention does not affect the normal production of paper tubes and silk spindles, and realizes online automatic detection of paper tube damage. Through the unified coordination of the conveying unit, image acquisition unit and rejecting unit, the timely, accurate and high-speed removal of damaged paper tubes is realized.

Owner:杭州慧知连科技有限公司

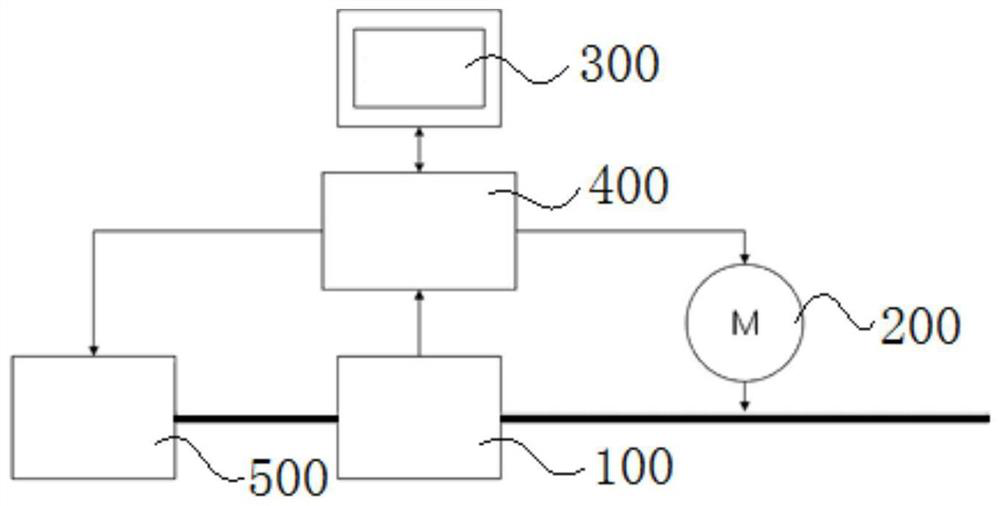

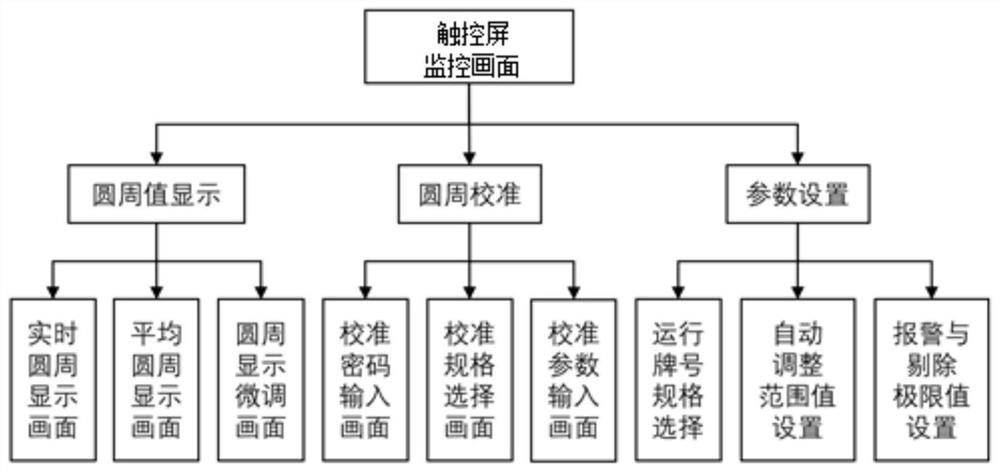

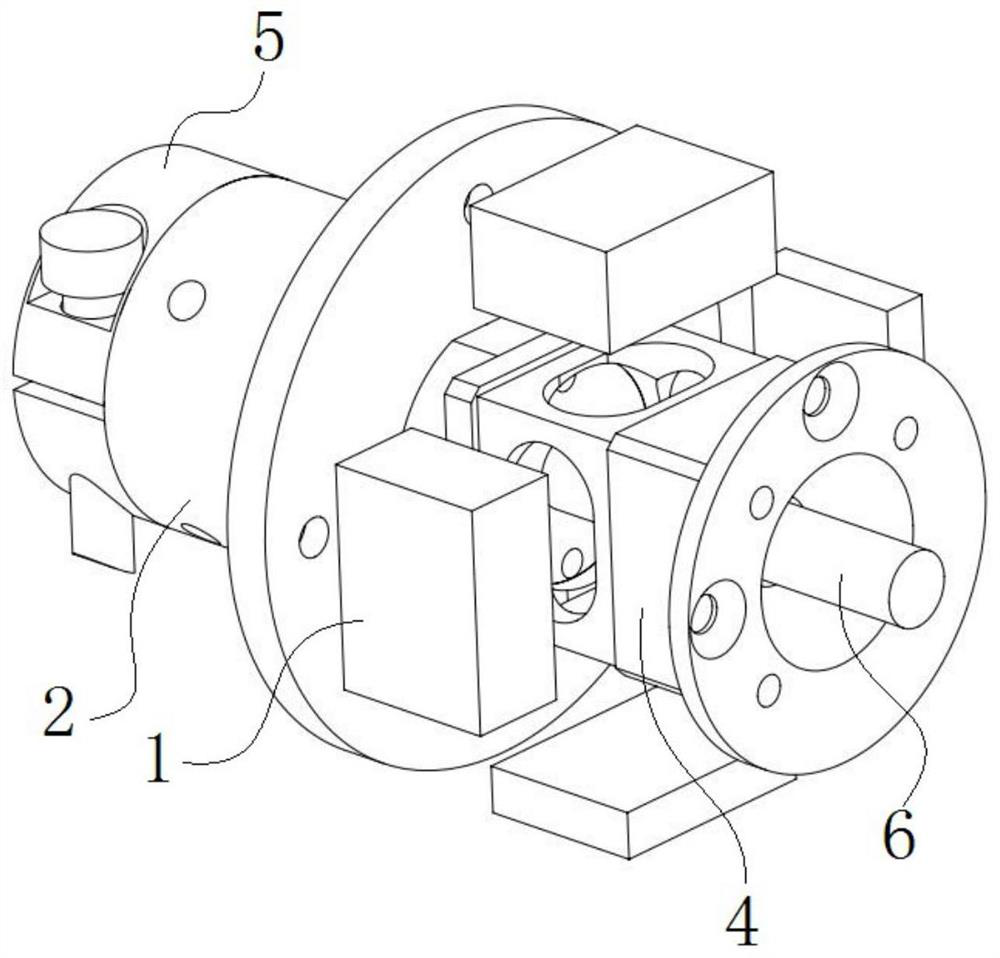

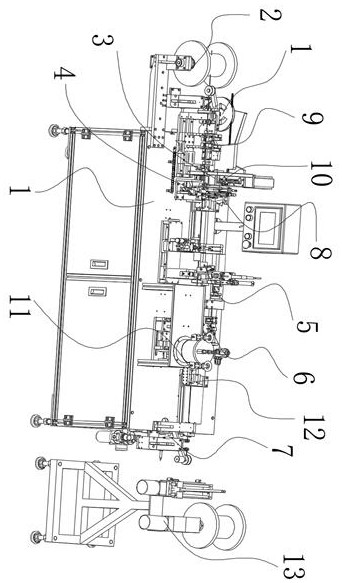

Cigarette filter stick circumference detection device and system

PendingCN112857239ARemoval in timeMake sure the production is qualifiedUsing optical meansComputer hardwareContinuous scanning

The invention relates to the technical field of cigarette production equipment, and in particular, relates to a cigarette filter stick circumference detection device and system. The device comprises a detection mechanism, a diameter adjusting mechanism, a touch screen and a PLC, wherein the detection mechanism, the diameter adjusting mechanism and the touch screen are electrically connected with the PLC; the diameter adjusting mechanism is located at the previous station of the detection mechanism, is controlled by the PLC and is used for adjusting the circumference size of the filter stick; the touch screen is used for displaying detection data and inputting an operation command to the PLC; and the detection mechanism is controlled by the PLC and is used for detecting the circumference of the filter stick and feeding back data to the PLC. A laser detector continuously scans and detects the circumference of the filter stick, a detection result is output to the PLC in an analog signal mode after being processed by a signal amplifier, the PLC receives an analog signal and converts the analog signal into the diameter or circumference value of the filter stick through calculation, and the circumference of the filter stick is adjusted in real time through the diameter adjusting mechanism; and meanwhile, the diameter or circumference value of the filter stick is displayed in real time through the touch screen.

Owner:CHINA TOBACCO GUANGDONG IND

A fully automatic assembly and welding process for led lamp beads

ActiveCN111360349BImprove assembly qualityImprove assembly efficiencySoldering apparatusPretreated surfacesEngineeringLED lamp

The invention discloses a fully automatic assembly and welding process of LED lamp beads. The assembly process is as follows: step S1, feeding and conveying process of accessory lamp strips; step S2, process of stripping, positioning and separating the accessory lamp strips; step S3, feeding of accessory LED lamps The conveying process; step S4, the process of picking up and transferring the manipulator to the turning mechanism; step S5, the process of picking up, transferring and turning the LED light that has been turned over by the manipulator, and entering the light installation process; step S6, the process of combining the accessory LED light and the light strip to form a light strip; step S7, pairing The self-assembled light strips are soldered; step S8, dispensing the soldered light strips; step S9, performing ultraviolet positioning and curing on the glue-dispensed light strips; step S10, curing and positioning the light strips Carry out the wire-releasing and tensioning process; step S11, wind and take-up the assembled light strip; the present invention realizes automatic assembly of LED light strips, improves production efficiency and quality, and has good market application value.

Owner:JIANGMEN CITY SEC LEE DI PHOTOELECTRIC LIGHTING CO LTD

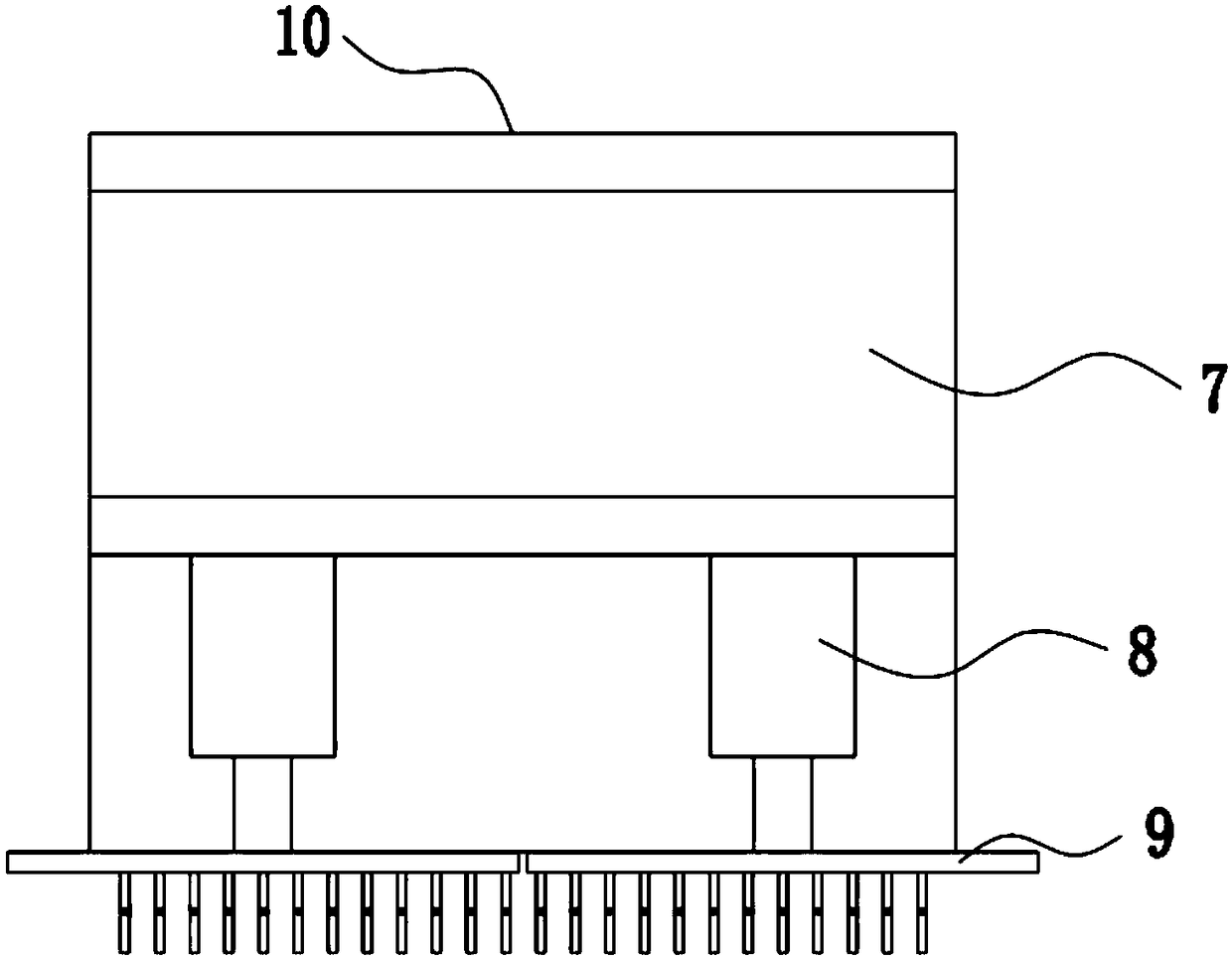

Capsule real-time inspection platform with dual detection

ActiveCN105234094BImprove drug qualityRemoval in timeMaterial analysis by optical meansSortingTime capsuleMaster controller

The invention relates to a real-time capsule checkout platform through double detection. The real-time capsule checkout platform through double detection comprises a near-infrared detecting mechanism, a visible light detecting mechanism and a master controller, wherein the near-infrared detecting mechanism and the visible light detecting mechanism performs defect detection on each capsule, the master controller is connected with the near-infrared detecting mechanism and the visible light detecting mechanism, and a capsule rejecting strategy is determined on the basis of defect detection results of the near-infrared detecting mechanism and the visible light detecting mechanism. By means of the real-time capsule checkout platform through double detection, to-be-checked capsules can be detected through two detecting modes, and the reliability of capsule detection is improved.

Owner:HAINAN BRIGHT FUTURE PHARMA

Real-time capsule checkout platform through double detection

ActiveCN105234094AImprove drug qualityRemoval in timeMaterial analysis by optical meansSortingTime capsuleMaster controller

The invention relates to a real-time capsule checkout platform through double detection. The real-time capsule checkout platform through double detection comprises a near-infrared detecting mechanism, a visible light detecting mechanism and a master controller, wherein the near-infrared detecting mechanism and the visible light detecting mechanism performs defect detection on each capsule, the master controller is connected with the near-infrared detecting mechanism and the visible light detecting mechanism, and a capsule rejecting strategy is determined on the basis of defect detection results of the near-infrared detecting mechanism and the visible light detecting mechanism. By means of the real-time capsule checkout platform through double detection, to-be-checked capsules can be detected through two detecting modes, and the reliability of capsule detection is improved.

Owner:HAINAN BRIGHT FUTURE PHARMA

The detection and classification method of the device based on the online detection and classification of chemical fiber silk ingot tripwire defects

ActiveCN109454006BDoes not affect normal productionClear "identityImage enhancementImage analysisFiberYarn

The invention discloses a device for on-line detection and classification of fiber tripping defects of chemical fiber spindles. The device comprises a spindle conveying device, an image acquisition device and a defect elimination module which are positioned on the spindle conveying device, and a good product waiting area and a bad product waiting area which are connected with the spindle conveyingdevice; the defect elimination module comprises an image processing and decision module, a quality statistical evaluation module and a defect control module; the image acquisition device comprises closed dark boxes, LED light source groups, CCD camera groups, image acquisition cards, digital signal processors and memories; the closed dark boxes are arranged above and below the silk ingot conveying device; and the LED light source groups, the CCD camera groups, the image acquisition cards, the digital signal processors and the memories are arranged in the closed dark boxes. The device has thefollowing beneficial effects that collected silk ingot images are processed by combining machine vision and an image processing technology, the interference number and morphological characteristics ofthe tripping fibers and interference fibers can be simultaneously detected, the fiber ingots with the fiber tripping defects can be detected by using detected fiber tripping information, and a sourcecan be traced by using statistical interference information.

Owner:杭州慧知连科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com