Chemical fiber filament spindle paper tube damage online detecting device and method

A detection device and detection method technology, applied in the direction of measurement device, material analysis by optical means, instrument, etc., can solve the problems of low accuracy, slow speed, false detection, etc., and achieve the effect of high-speed rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

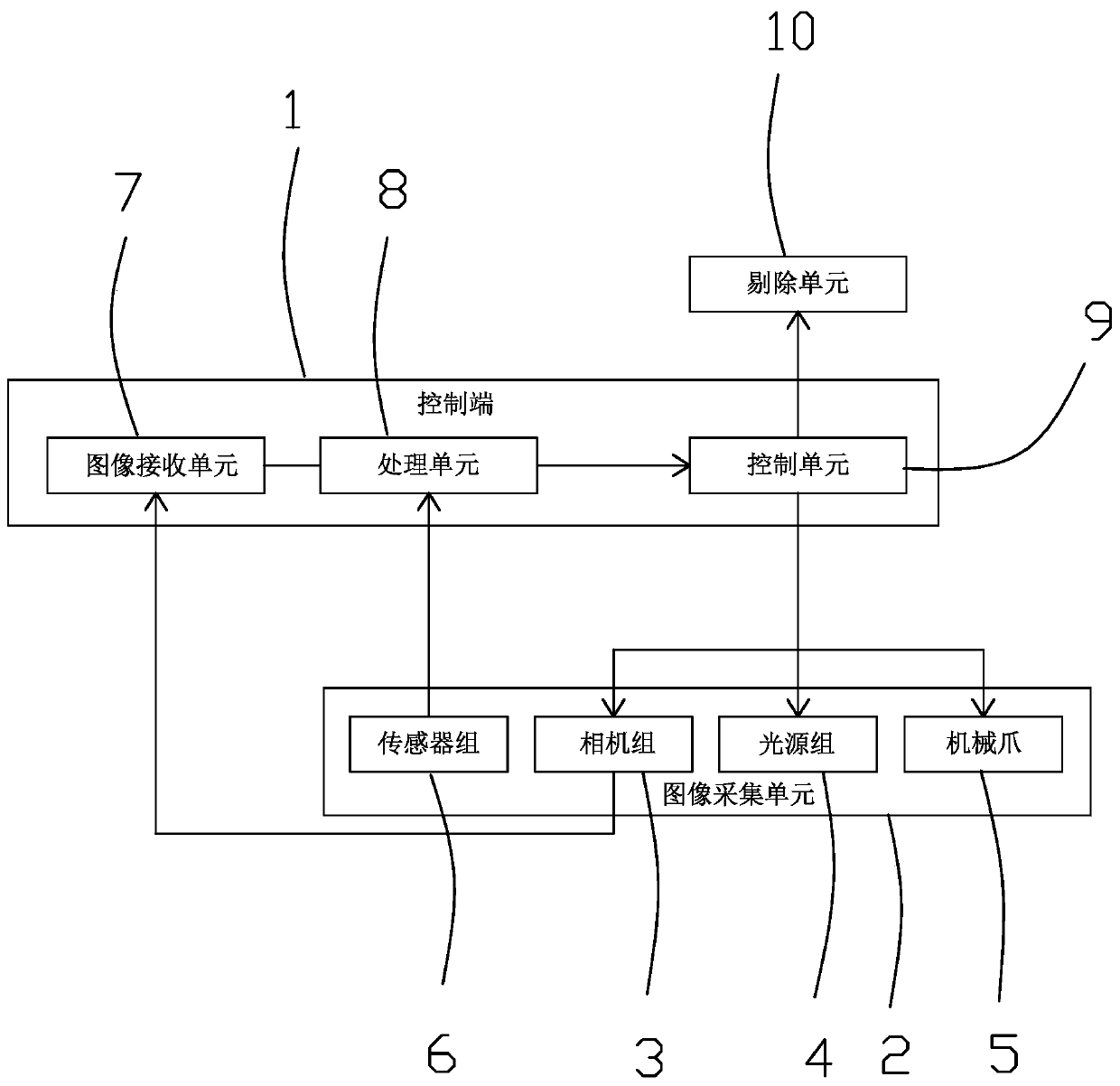

[0067] In this embodiment, an on-line detection device for the damage of a chemical fiber spindle paper tube, such as figure 1 As shown, including the transmission unit, the control terminal 1, where

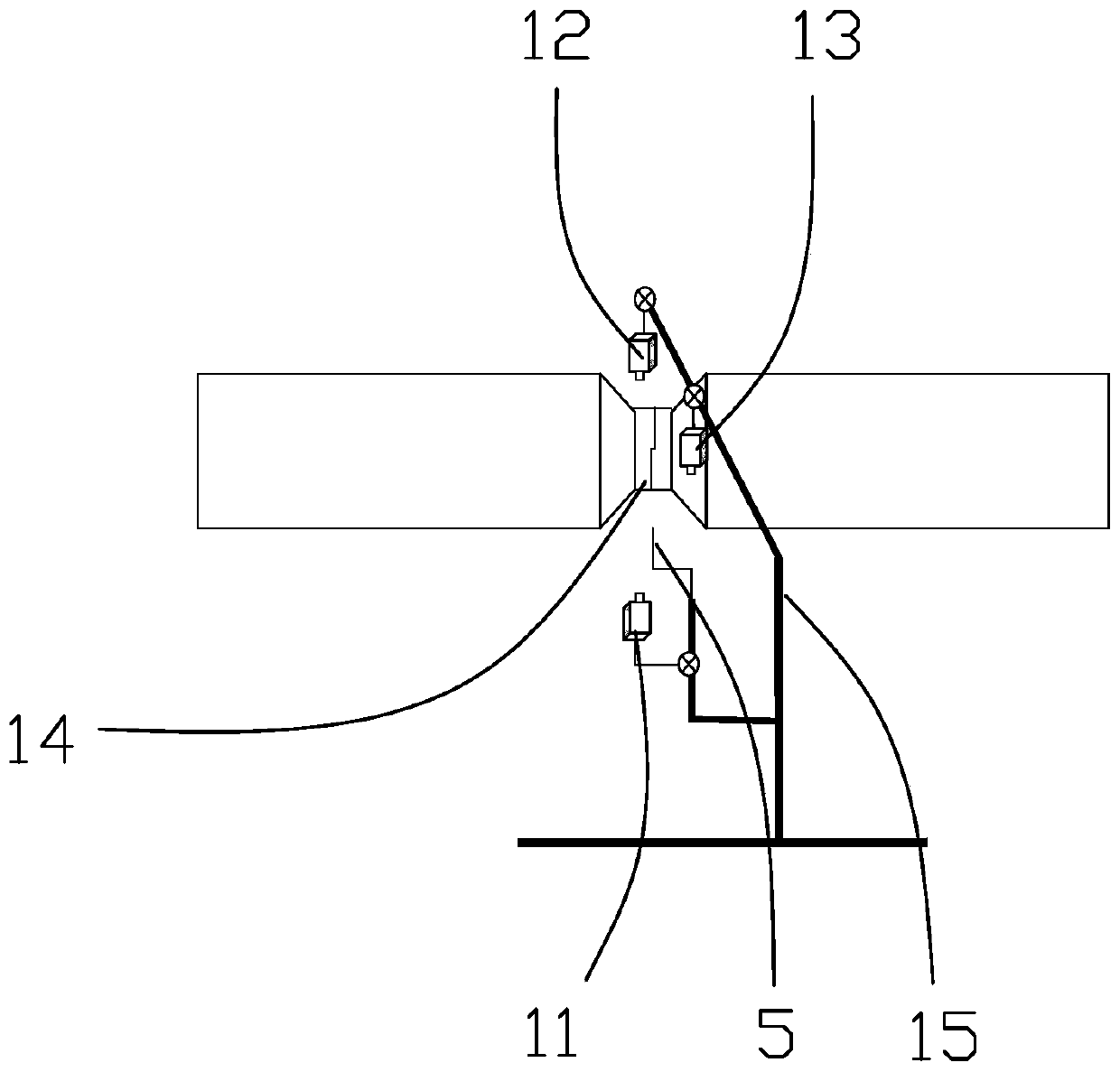

[0068] The transmission unit is used to transport the paper tubes, the detection area on the transmission unit is provided with a rejecting unit 10 for sorting the paper tubes, and an image acquisition unit 2 is located around the rejecting unit for image acquisition of the paper tubes; the paper tubes are placed in the automatic production line There are two different states before winding and after winding. For the state before winding, there is no filament on the paper tube, and the paper tube enters the conveying unit in a horizontal rolling manner, while for the state after winding, the paper tube Filament is already attached to it, and the spindles are loaded from the tray into the transfer unit in an upright manner.

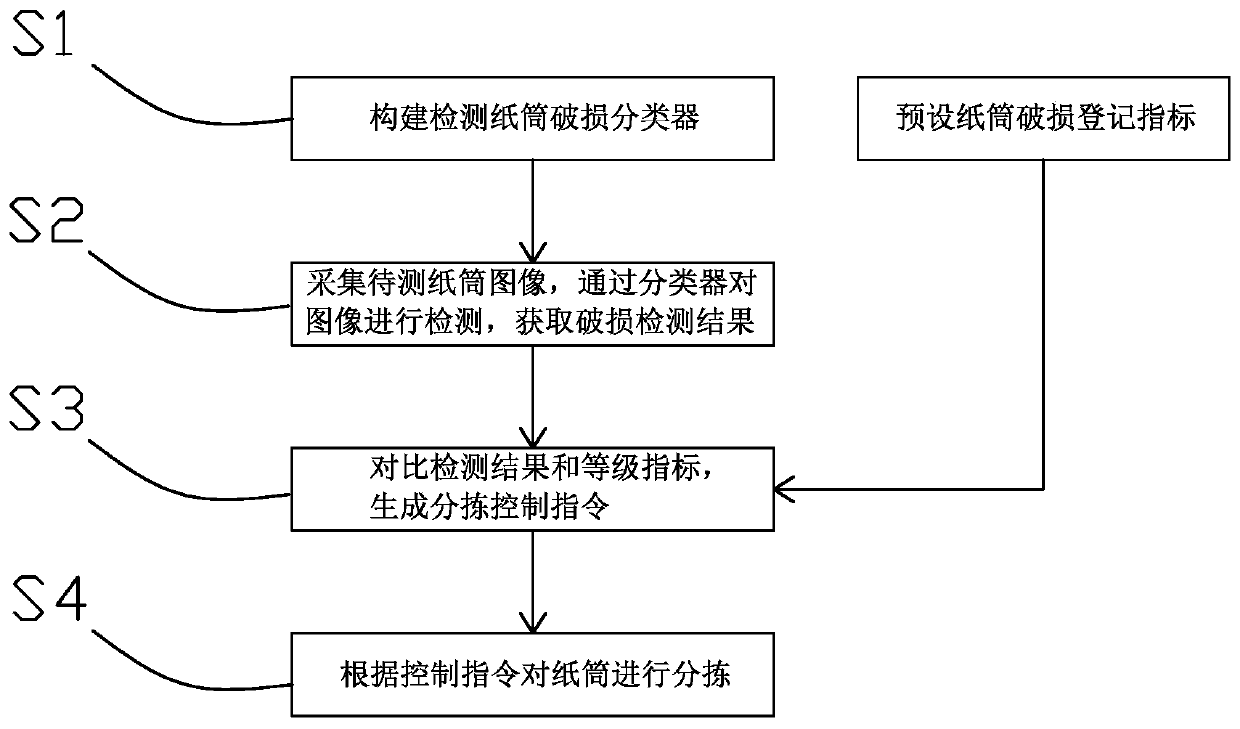

[0069] The control end has a classifier for detecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com