Real-time capsule checkout platform through double detection

A dual detection, capsule technology, applied in measuring devices, instruments, sorting, etc., can solve the problems of slow speed, low efficiency, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiment of the capsule real-time inspection platform using dual detection of the present invention will be described in detail below with reference to the accompanying drawings.

[0016] The severity of capsule defects indirectly determines the quality of its packaged medicines. Therefore, in order to improve the quality of medicines, we must first start from overcoming capsule defects. However, the capsule detection method in the prior art mainly adopts a manual method, which has low efficiency and low reliability.

[0017] In order to overcome the above deficiencies, the present invention builds a real-time inspection platform for capsules that adopts double detection. Through the double detection mode of near-infrared detection and visible light detection, it avoids the occurrence of missed detection of defective capsules. The introduction of the mechanism has greatly improved the automation level of capsule detection.

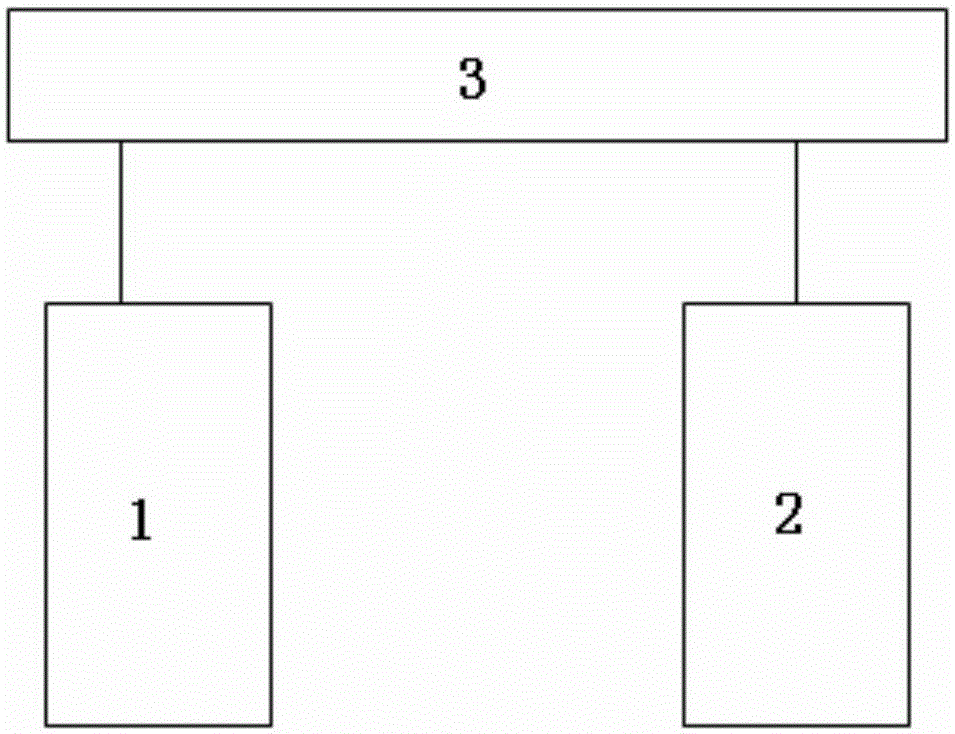

[0018] figure 1 It is a structural bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com