The detection and classification method of the device based on the online detection and classification of chemical fiber silk ingot tripwire defects

A grading method and wire ingot technology, applied in the field of on-line detection of trip wire defects, can solve the problems of low accuracy, detection lag, and serious false detection by automatic detection systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described below in conjunction with the drawings and specific embodiments:

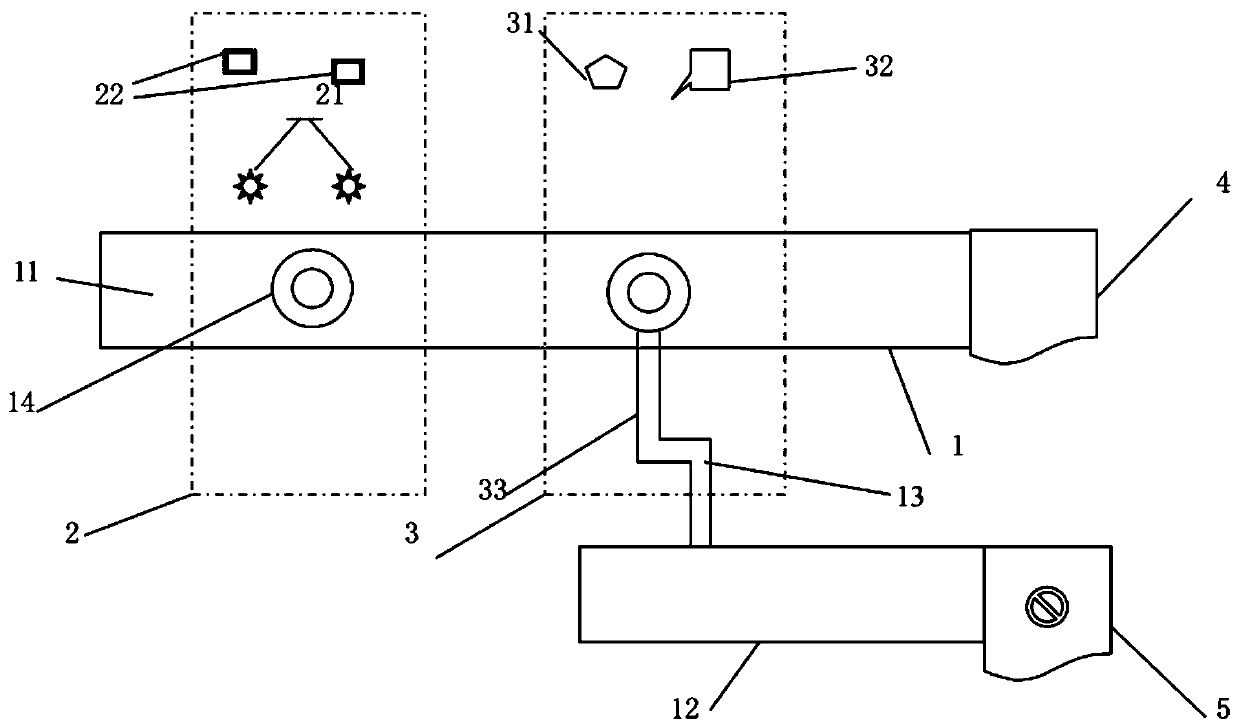

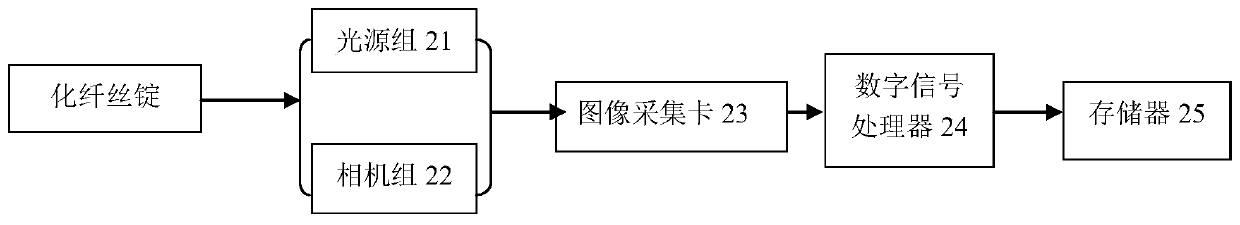

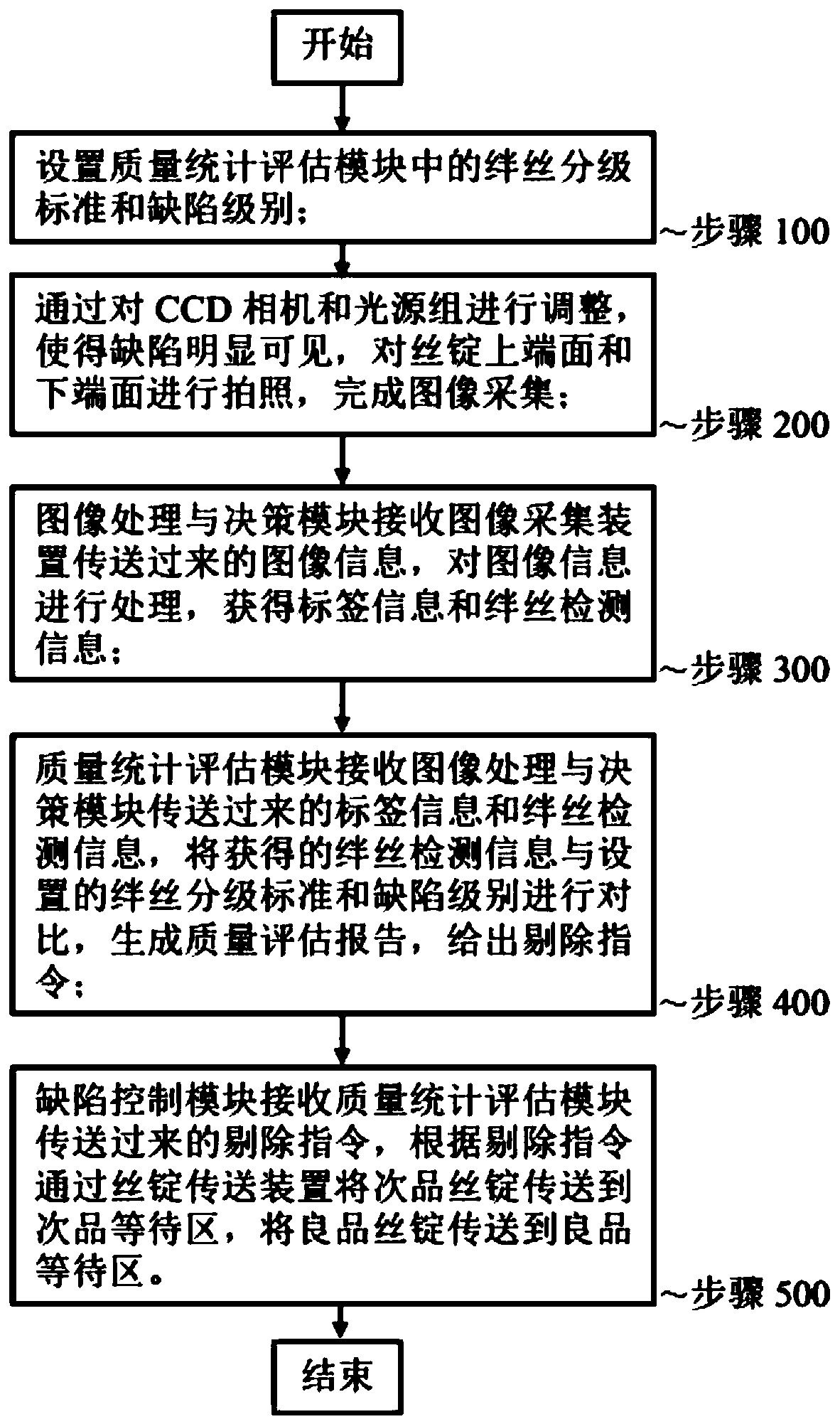

[0084] Such as figure 1 The embodiment shown is a device for online detection and classification of chemical fiber spindles' tripped wire defects. It includes a spindle conveying device 1, an image acquisition device 2 located on the spindle conveying device, and a defect rejection module 3, and a silk spindle conveying device Connected good product waiting area 4 and defective product waiting area 5; the defect rejection module includes an image processing and decision-making module 31, a quality statistical evaluation module 32, and a defect control module 33; the silk spindle conveying device includes a main conveyor belt 11 and an auxiliary conveyor belt 12. Conveying distribution device 13, tray 14 and tray fastening device; the tray is fastened on the main conveyor belt and the auxiliary conveyor belt by the tray fastening device, and the main conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com