Process for Bayer process aluminum oxide production by replacing carbide slag with lime

A technology of calcium carbide slag and alumina, which is applied to the removal of alumina/hydroxide and solid waste, can solve the problems of high cost, adverse impact on the surrounding environment, and occupation of land, so as to solve the problem of difficult storage and realize the recycling of waste , The effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The process of using calcium carbide slag instead of lime for Bayer process alumina production includes the following steps:

[0020] (1) the waste calcium carbide slag that chemical plant produces PVC, moisture content is at 25% (wt%), and available calcium oxide content is sent to ash tank at 55% (wt%), through with settling tank once washing liquid ( The caustic concentration of the solution is mixed and stirred at 50g / L), and it is configured into a calcium carbide slag slurry with an effective calcium oxide content of 50g / L;

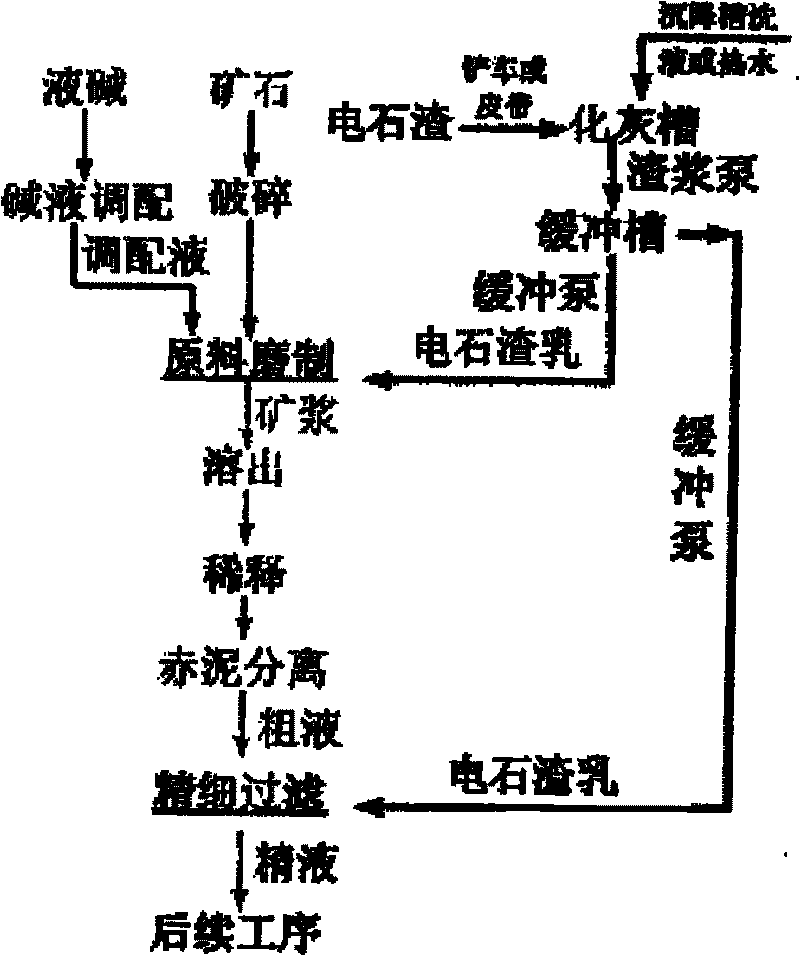

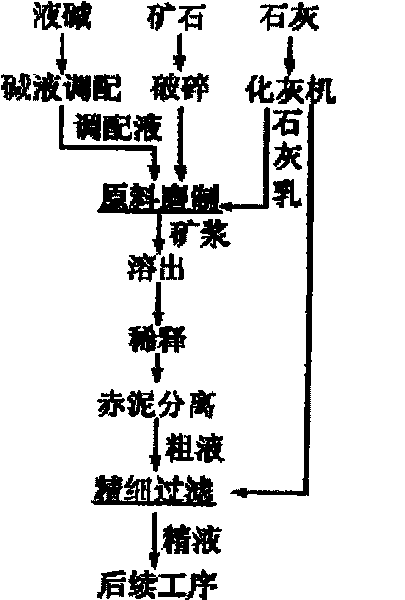

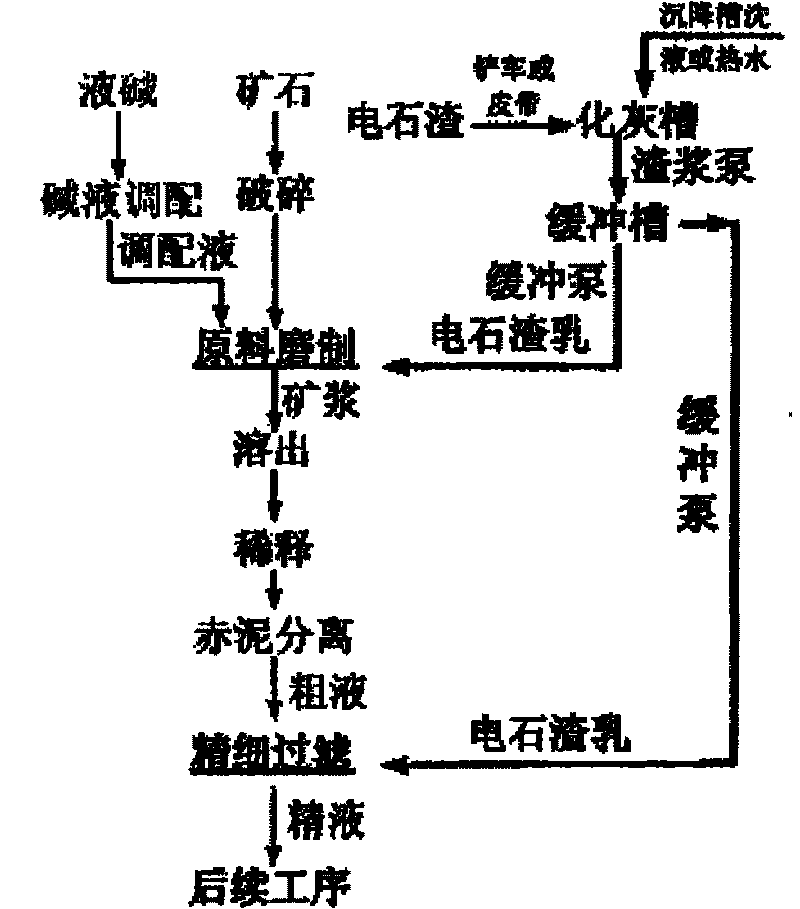

[0021] (2) The calcium carbide slag slurry is pumped to the buffer tank through the slurry pump. Part of the calcium carbide slag milk in the buffer tank is sent to the raw material grinding process through the buffer pump, and the other part is sent to the fine filtration process of the crude liquid after the sedimentation red mud is separated. filter aid;

[0022] (3) After causticizing the milk of lime and mixing it with lye, the crushed ...

Embodiment 2

[0026] The process of using calcium carbide slag instead of lime for Bayer process alumina production includes the following steps:

[0027] (1) The waste carbide slag of PVC produced by the chemical plant, with a moisture content of 40% (wt%) and an effective calcium oxide content of 60% (wt%), is sent to the ash tank, mixed with hot water, and configured Form calcium carbide slag slurry with an effective calcium oxide content of 300g / L;

[0028] (2) The calcium carbide slag slurry is pumped to the buffer tank through the slurry pump. Part of the calcium carbide slag milk in the buffer tank is sent to the raw material grinding process through the buffer pump, and the other part is sent to the fine filtration process of the crude liquid after the sedimentation red mud is separated. filter aid;

[0029] (3) After causticizing the milk of lime and mixing it with lye, the crushed ore and calcium carbide slag milk are put into the raw material mill for wet grinding. The amount of...

Embodiment 3

[0033] The process of using calcium carbide slag instead of lime for Bayer process alumina production includes the following steps:

[0034] (1) The waste carbide slag of PVC produced by the chemical plant, with a moisture content of 30% (wt%) and an effective calcium oxide content of 60% (wt%), is sent to the ash tank, through the secondary washing with the settling tank (the caustic alkali concentration of solution is at 100g / L) mixing and stirring, is configured into the calcium carbide slag slurry of effective calcium oxide content 150g / L;

[0035] (2) The calcium carbide slag slurry is pumped to the buffer tank through the slurry pump. Part of the calcium carbide slag milk in the buffer tank is sent to the raw material grinding process through the buffer pump, and the other part is sent to the fine filtration process of the crude liquid after the sedimentation red mud is separated. filter aid;

[0036] (3) After causticizing the milk of lime and mixing it with lye, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com