Wax ripeness stage corn seed flour fermented feed and preparation method and application thereof

A technology of fermented feed and wax ripening period, applied in the direction of bacteria, application, animal feed, etc. used in food preparation, can solve the problems of mildew, rancidity, etc., achieve the form of black feces, reduce the ratio of material to meat, and has good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

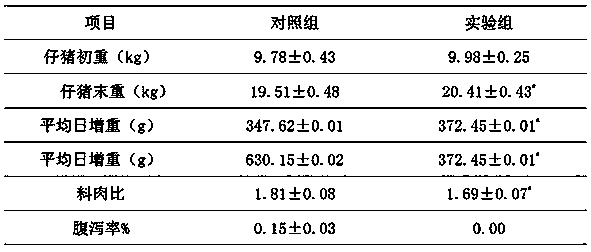

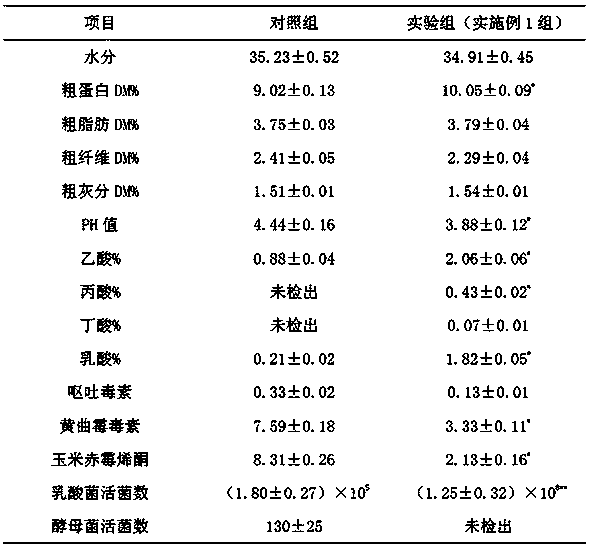

Embodiment 1

[0028] Preparation of corn seed powder fermented feed in the wax ripening stage in this example: Harvest wax ripe corn in the field, and threshing, the moisture content was determined to be 34.5%. A wet corn pulverizer is used for pulverization, and the aperture of the sieve is 6mm on one side and 8mm on the other side. The crushed corn flour is conveyed by conveyor belt. Set up a small nozzle at the position where the conveyor belt is close to the discharge port of the pulverizer, and the small nozzle is used to spray the compound bacteria liquid. The spraying amount of the composite bacterial solution is calculated as 2%, that is, 1 ton of corn flour is sprayed with 20kg of the composite bacterial solution. The preparation method of the compound bacteria liquid: according to the proportion by weight, take 1g Lactobacillus buchneri (100 billion cfu / g), 1g Pentosococcus (10 billion cfu / g), 0.5g Lactobacillus plantarum (10 billion cfu / g) g), 0.15g of Pediococcus lactis (10 bi...

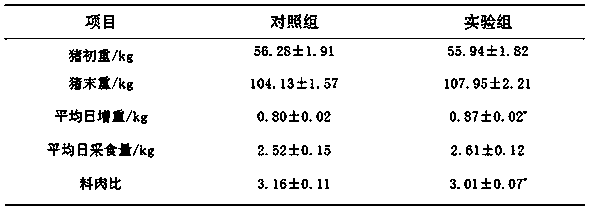

Embodiment 2

[0034]The preparation of the fermented feed of corn seed meal in the wax ripening stage in this example: the wax ripe corn was harvested in the field and threshed, and the moisture content was determined to be 30%. A wet corn pulverizer is used for crushing, and the aperture of the sieve is 7mm on one side and 7mm on the other side. The crushed corn flour is conveyed by conveyor belt. Set up a small nozzle at the position where the conveyor belt is close to the discharge port of the pulverizer, and the small nozzle is used to spray the compound bacteria liquid. The spraying amount of the composite bacterial solution is calculated as 1.5%, that is, 1 ton of corn flour is sprayed with 15kg of the composite bacterial solution. The preparation method of the compound bacteria liquid: according to the proportion by weight, take 1g Lactobacillus buchneri (100 billion cfu / g), 1g Pentosococcus (10 billion cfu / g), 0.5g Lactobacillus plantarum (10 billion cfu / g) g), 0.15g of Pediococcu...

Embodiment 3

[0037] The preparation of the fermented feed of corn seed meal in the wax ripening stage in this example: the wax ripe corn was harvested in the field and threshed, and the moisture content was determined to be 30%. A wet corn pulverizer is used for pulverization, and the aperture of the sieve is 8mm on one side and 6mm on the other side. The crushed corn flour is conveyed by conveyor belt. Set up a small nozzle at the position where the conveyor belt is close to the discharge port of the pulverizer, and the small nozzle is used to spray the compound bacteria liquid. The spraying amount of the composite bacterial solution is calculated as 2.5%, that is, 1 ton of corn flour is sprayed with 55kg of the composite bacterial solution. The preparation method of the compound bacteria liquid: according to the proportion by weight, take 1g Lactobacillus buchneri (100 billion cfu / g), 1g Pentosococcus (10 billion cfu / g), 0.5g Lactobacillus plantarum (10 billion cfu / g) g), 0.15g of Pedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com